Outlet water collecting device for extrusion die for specially-shaped plastic materials

A technology of extrusion die and collection device, applied in the field of water outlet collection device of plastic profiled material extrusion die, can solve the problems of easy slippage of operators, ineffective operation of equipment, water affecting work, etc., so as to avoid splashing everywhere, reduce Mold cost, reduce the effect of processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

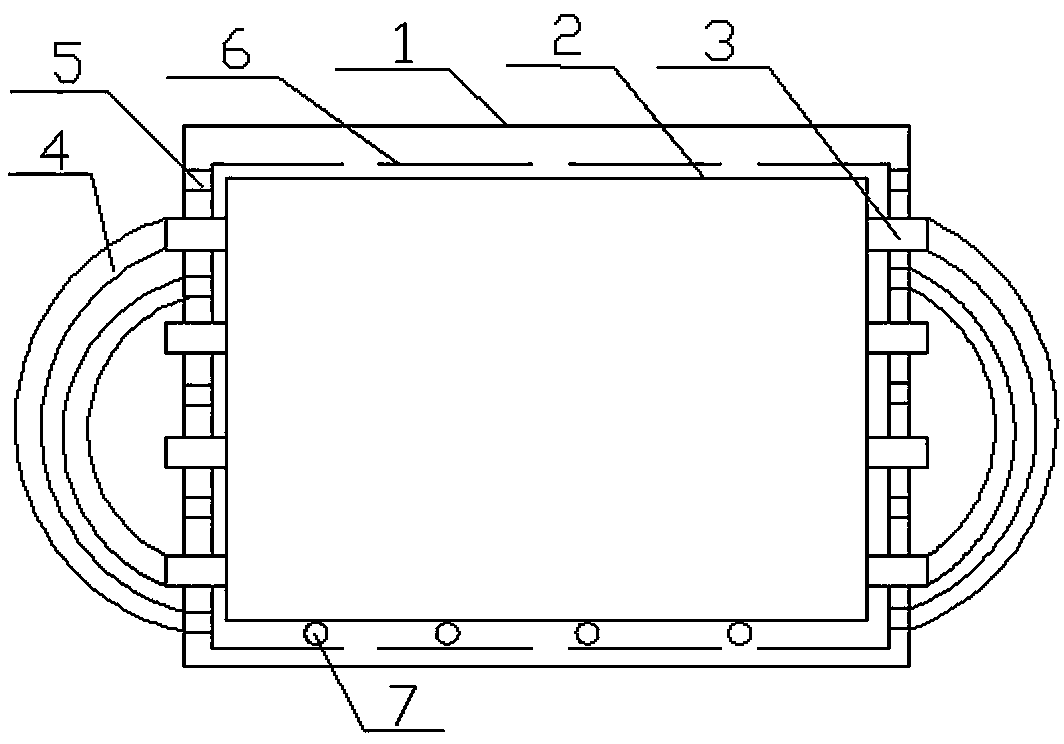

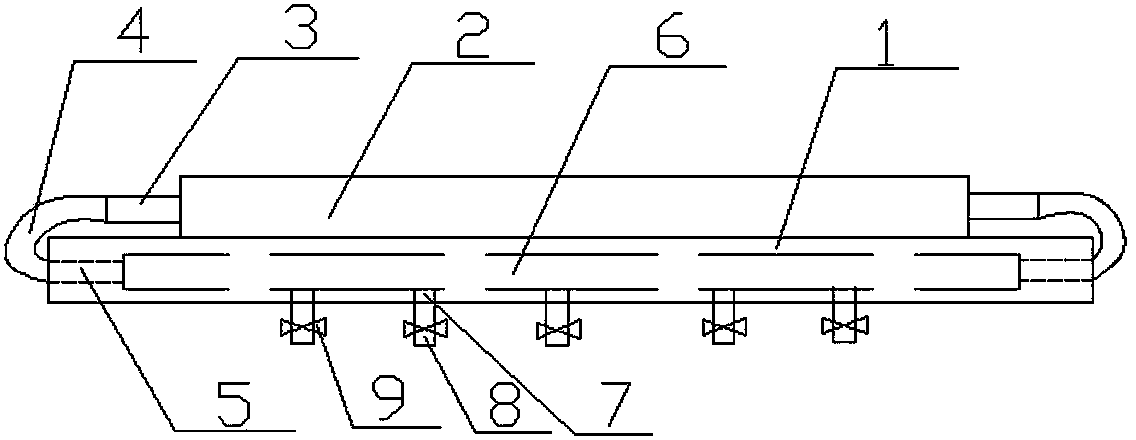

[0015] As shown in the figure, a plastic shaped material extrusion mold outlet water collection device includes a base plate 1 and a template 2 installed on the base plate 1, wherein there can be multiple templates 2, and each template 2 is equipped with multiple outlets Nozzle 3, each outlet nozzle 3 is connected with a water outlet pipe 4, the end of each outlet pipe 4 is connected with a water inlet hole 5 correspondingly arranged on the side wall of the bottom plate 1, and the outlet pipe 4 is connected with the water outlet nozzle 3 and The joints of the water inlet holes 5 are all provided with sealing gaskets, and the water in the outlet pipe 4 flows through the water inlet holes 5 and is collected into the water collecting chamber 6 arranged inside the bottom plate 1. The water hole 5 is a vertical diversion hole 7, and the water in the water collection chamber 6 flows out through a plurality of diversion holes 7 to reduce the pressure of the water flow by changing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com