Collapse enhancer for water glass sand

A technology of water glass sand and reinforcing agent, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of poor collapsibility and deterioration of sand mold performance, and achieve the effects of improving collapsibility, reducing residual strength and increasing molding sand strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 74 grams of quartz powder and add it into the mixing bucket, and stir evenly. Take by weighing 9.8 grams of graphite powder with a particle diameter of 500 mesh, 0.2 grams of graphene, 10 grams of aluminum oxide powder with a particle diameter of 500 mesh, 5 grams of lithium-based bentonite, and 1 gram of organic silicon surfactant, and add them in the mixing tank successively and mix To uniformity, obtain the water glass collapsing enhancer.

Embodiment 2-5

[0037] Its preparation method is the same as that of Example 1, except that the raw material components and their addition amounts are the same, and the specific components and proportions are shown in Table 1.

[0038] Table 1

[0039]

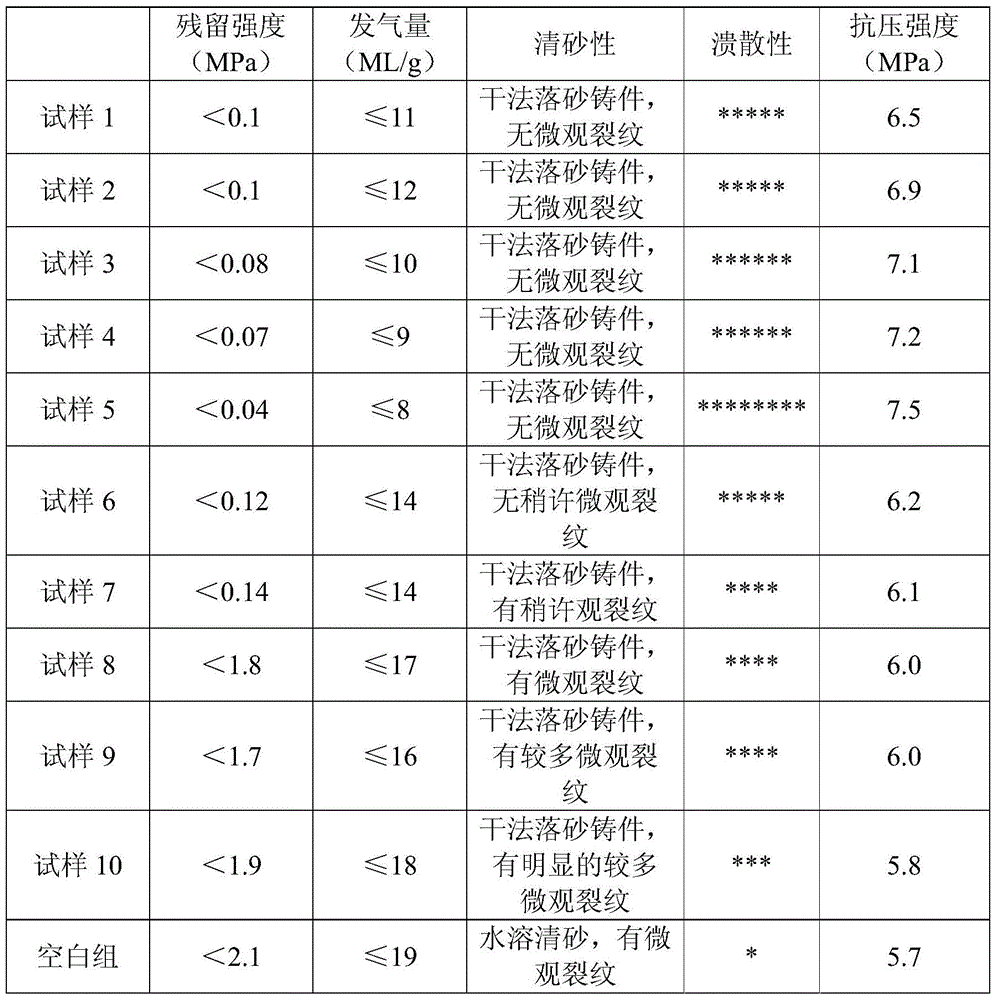

[0040] The water glass collapsing enhancer prepared in Examples 1-10 was added to standard sand and water glass respectively below, and samples 1-10 were prepared respectively to test its performance.

[0041] Take 10 parts of 2kg50 / 100 mesh Dalin standard sand, add 60g of sodium water glass to each part, and correspondingly add 20g of the water glass collapsing enhancer prepared in Example 1-10, stir with SHY resin sand sand mixer for 90 seconds After discharge, 10 parts of mixed material were obtained.

[0042] 10 parts of the mixture were heated at 160°C for 60 seconds (the core-making equipment is A1 warm core box sample machine produced by Suzhou Meiji Technology), and seven samples with a diameter of 50mm and a height of 50mm were p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com