Titanium dioxide/silicon dioxide nanometer composite material and preparation method and application thereof

A nano-composite material, silicon dioxide technology, applied in the application of titanium dioxide/silicon dioxide nano-composite material in photocatalytic degradation of organic dyes, titanium dioxide/silicon dioxide nano-composite material and its preparation field, can solve high cost, The actual utilization rate of titanium dioxide is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a preparation method of titanium dioxide / silicon dioxide nanocomposite material, the preparation method comprising:

[0023] A, the process of preparing nano-silica sol by sol method;

[0024] b, in the presence of a solvent, mixing the nano-silica sol, cetyltrimethylammonium bromide, and tetrabutyl titanate and carrying out a contact reaction to obtain a pale yellow precipitate;

[0025] c. The process of mixing the pale yellow precipitate, hydrochloric acid and acetone and refluxing to prepare a titanium dioxide / silicon dioxide nanocomposite material.

[0026] In step b, the amount of each substance can be selected in a wide range. In order to improve the yield of the light yellow precipitate and control the thickness of the coating layer on the outer surface of the titanium dioxide shell, preferably, relative to 100 parts by weight of the Nano silica sol, the consumption of described hexadecyltrimethylammonium bromide is 5-15 parts by weight, ...

Embodiment 1

[0044] 1) Preparation of white silicic acid sol: at 30°C, mix 28g of ethanol, 0.6g of ammonia water, 4.5g of water, and 1g of ethyl orthosilicate for 8 hours to obtain a white silicic acid sol, then centrifuge the white silicic acid sol, and use Distilled water, ethanol and distilled water washing;

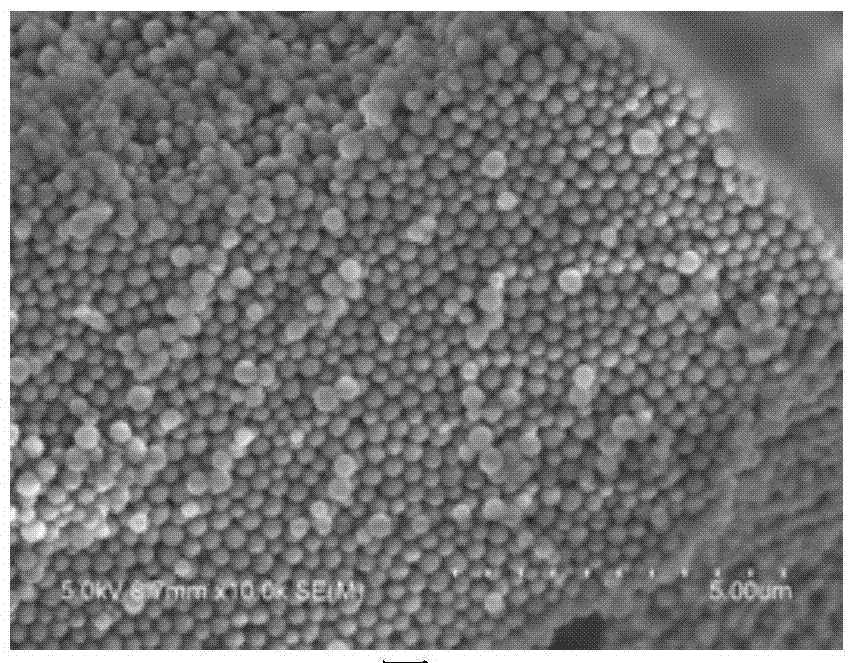

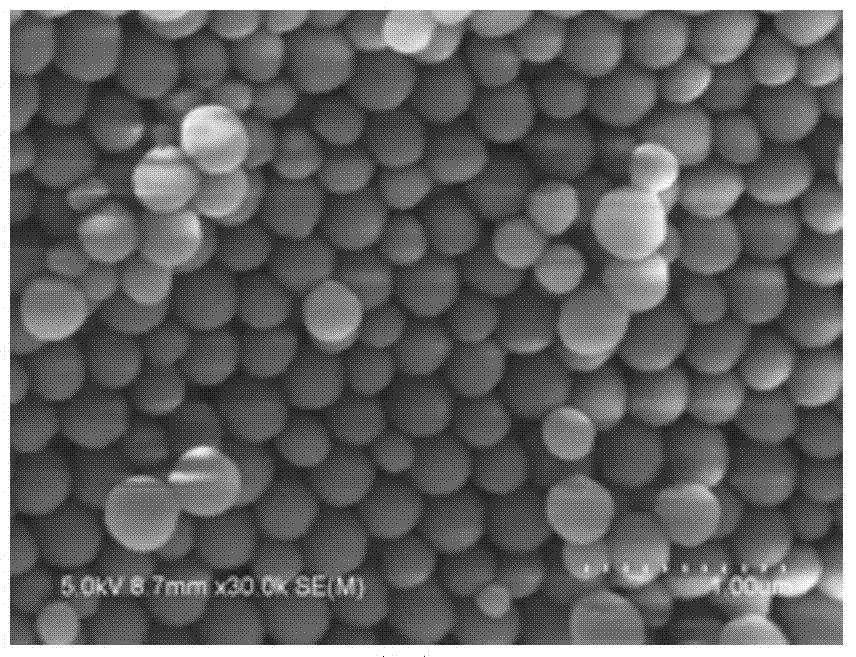

[0045] 2) Preparation of light yellow sol: mix 1g of white silicic acid, 18g of ethanol, 0.1g of cetyltrimethylammonium bromide, 0.04g of resorcinol, 0.14g of formaldehyde and 0.15g of ammonia water and mix them at 55°C After reacting for 2 hours, a light yellow sol was obtained, which was collected by centrifugation and washed with distilled water, absolute ethanol and distilled water in sequence. The light yellow sol was subjected to SEM detection, and the results were as follows figure 1 and figure 2 As shown in the figure, it can be seen that the nano-silica is spherical and the average particle size is 250nm.

[0046] 3) Preparation of light yellow precipitate: at 30°C, m...

Embodiment 2

[0051] 1) Preparation of white silicic acid sol: At 45°C, mix 30g of ethanol, 0.7g of ammonia water, 5g of water, and 1g of ethyl orthosilicate for 12 hours to obtain a white silicic acid sol, then centrifuge the white silicic acid sol, and successively wash with distilled water , ethanol and distilled water washing;

[0052] 2) Preparation of light yellow sol: mix 1g of white silicic acid, 30g of ethanol, 0.15g of cetyltrimethylammonium bromide, 0.06g of resorcinol, 0.18g of formaldehyde and 0.2g of ammonia water and mix them at 60°C After reacting for 3 hours, a light yellow sol was obtained, which was collected by centrifugation and washed with distilled water, absolute ethanol and distilled water in sequence.

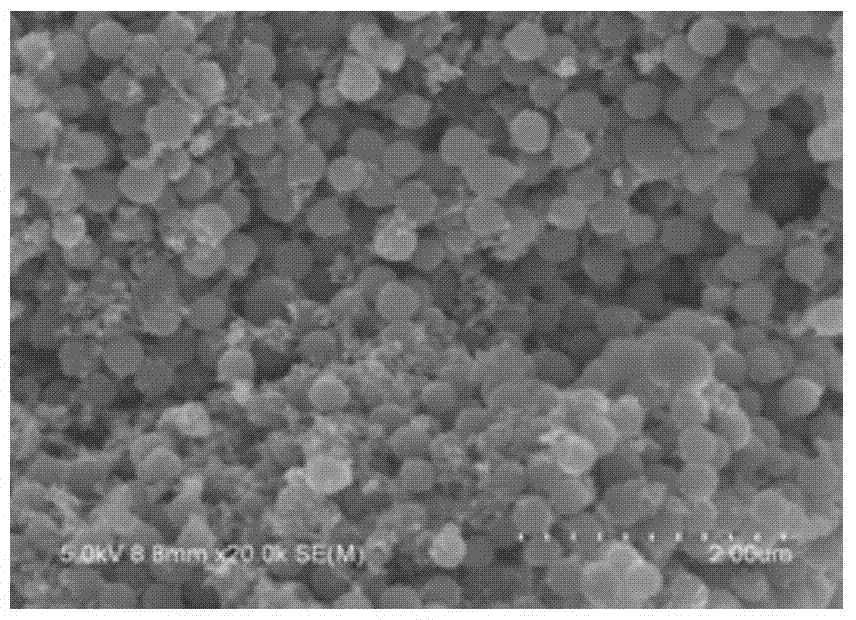

[0053] 3) Preparation of light yellow precipitate: at 35°C, mix 1 g of light yellow sol, 0.15 g of cetyltrimethylammonium bromide, 30 g of ethanol and 0.1 g of water, then add 0.3 g of tetrabutyl titanate to react 12h, a pale yellow precipitate was obtained. The l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com