Tobacco stem pressing and shredding technology

A processing technology and tobacco stem technology, which is applied in the field of tobacco stem pressing and shredded processing technology, to achieve the effects of uniform expansion, improved processing resistance, and improved sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

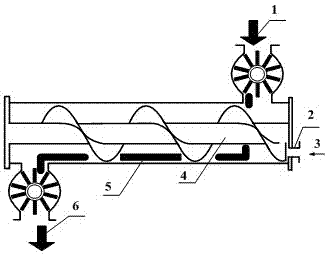

Image

Examples

Embodiment 1

[0039] A tobacco stem pressing and shredding process, including tobacco stem high-temperature, high-pressure and decompression pretreatment, tobacco stem microwave expansion, tobacco stem humidification and stem storage, tobacco stem heating and humidification, tobacco stem pre-pressing, secondary stem pressing, Three-stage pressing of stems, feeding of stem slices, shredding of stem slices, shaping and drying of cut stems, flavoring and storage of cut stems; details are as follows:

[0040] (1) High-temperature, high-pressure and decompression pretreatment of tobacco stems: put the tobacco stems into high-temperature and high-pressure equipment, and use saturated steam at a temperature of 100-190°C and a pressure of 1-1.2 bar to pretreat the tobacco stems for 4-6 minutes. Tobacco stems are conveyed by screw from high-pressure state and then released to normal pressure to realize expansion. The temperature of pretreated tobacco stems is 50°C-60°C, and the moisture content is co...

Embodiment 2

[0053] A tobacco stem pressing and shredding process, including tobacco stem high-temperature, high-pressure and decompression pretreatment, tobacco stem microwave expansion, tobacco stem humidification and stem storage, tobacco stem heating and humidification, tobacco stem pre-pressing, secondary stem pressing, Three-stage pressing of stems, feeding of stem slices, shredding of stem slices, shaping and drying of cut stems, flavoring and storage of cut stems; details are as follows:

[0054] (1) High-temperature, high-pressure and decompression pretreatment of tobacco stems: put the tobacco stems into high-temperature and high-pressure equipment, and use saturated steam at a temperature of 100-190°C and a pressure of 1-1.2 bar to pretreat the tobacco stems for 4-6 minutes. Tobacco stems are conveyed by screw from high-pressure state and then released to normal pressure to realize expansion. The temperature of pretreated tobacco stems is 50°C-60°C, and the moisture content is co...

Embodiment 3

[0067] A tobacco stem pressing and shredding process, including tobacco stem high-temperature, high-pressure and decompression pretreatment, tobacco stem microwave expansion, tobacco stem humidification and stem storage, tobacco stem heating and humidification, tobacco stem pre-pressing, secondary stem pressing, Three-stage pressing of stems, feeding of stem slices, shredding of stem slices, shaping and drying of cut stems, flavoring and storage of cut stems; details are as follows:

[0068] (1) High-temperature, high-pressure and decompression pretreatment of tobacco stems: put the tobacco stems into high-temperature and high-pressure equipment, and use saturated steam at a temperature of 100-190°C and a pressure of 1-1.2 bar to pretreat the tobacco stems for 4-6 minutes. Tobacco stems are conveyed by screw from high-pressure state and then released to normal pressure to realize expansion. The temperature of pretreated tobacco stems is 50°C-60°C, and the moisture content is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com