Freezing-resisting soybean protein isolate and preparation method thereof

A technology for soybean protein isolate and freeze resistance, which is applied in the field of freeze-resistant soybean protein isolate and its preparation, can solve the problems of water retention of soybean protein isolate gel and the like, and achieves broad industrial application prospects, simple process, and no equipment required. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

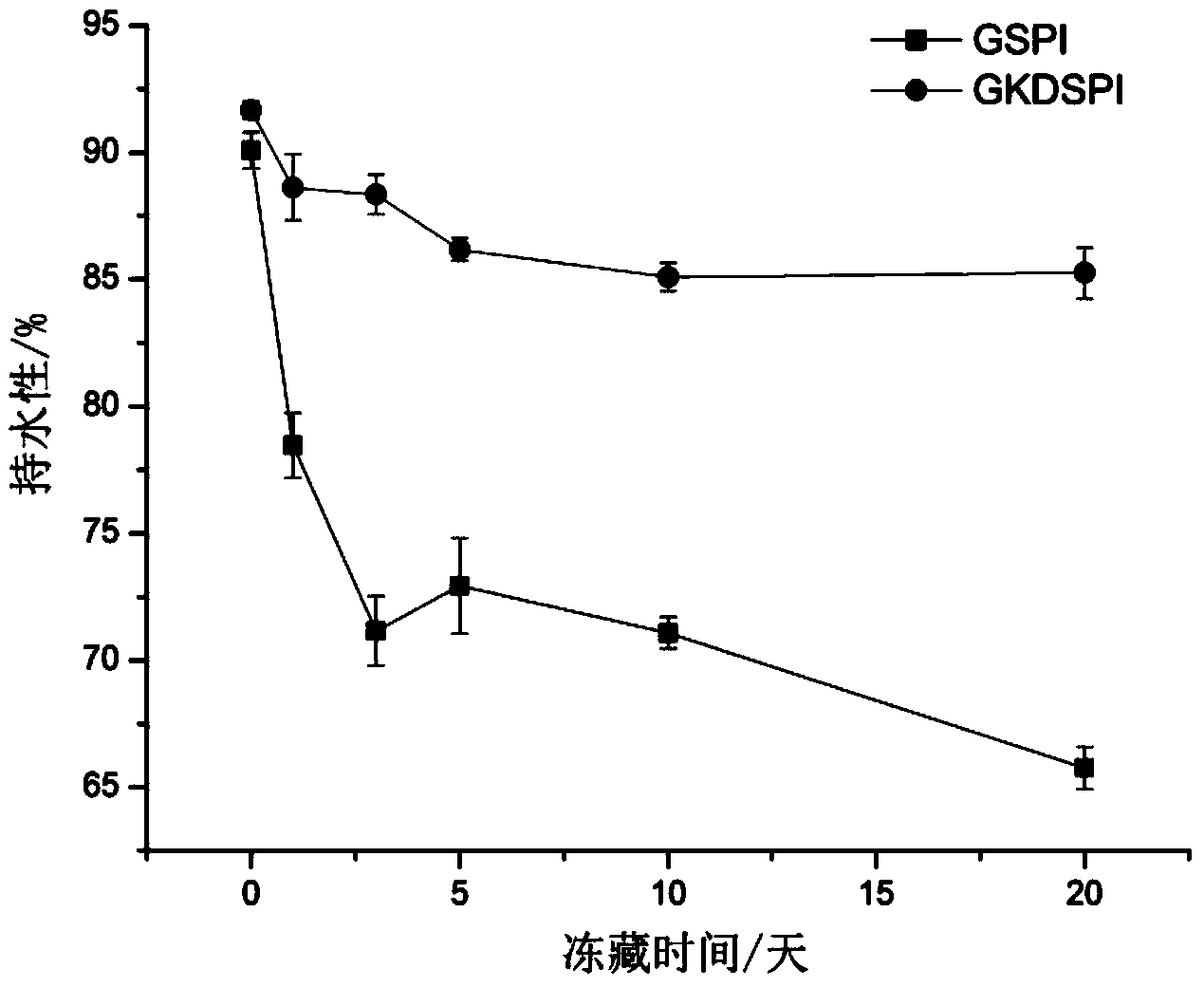

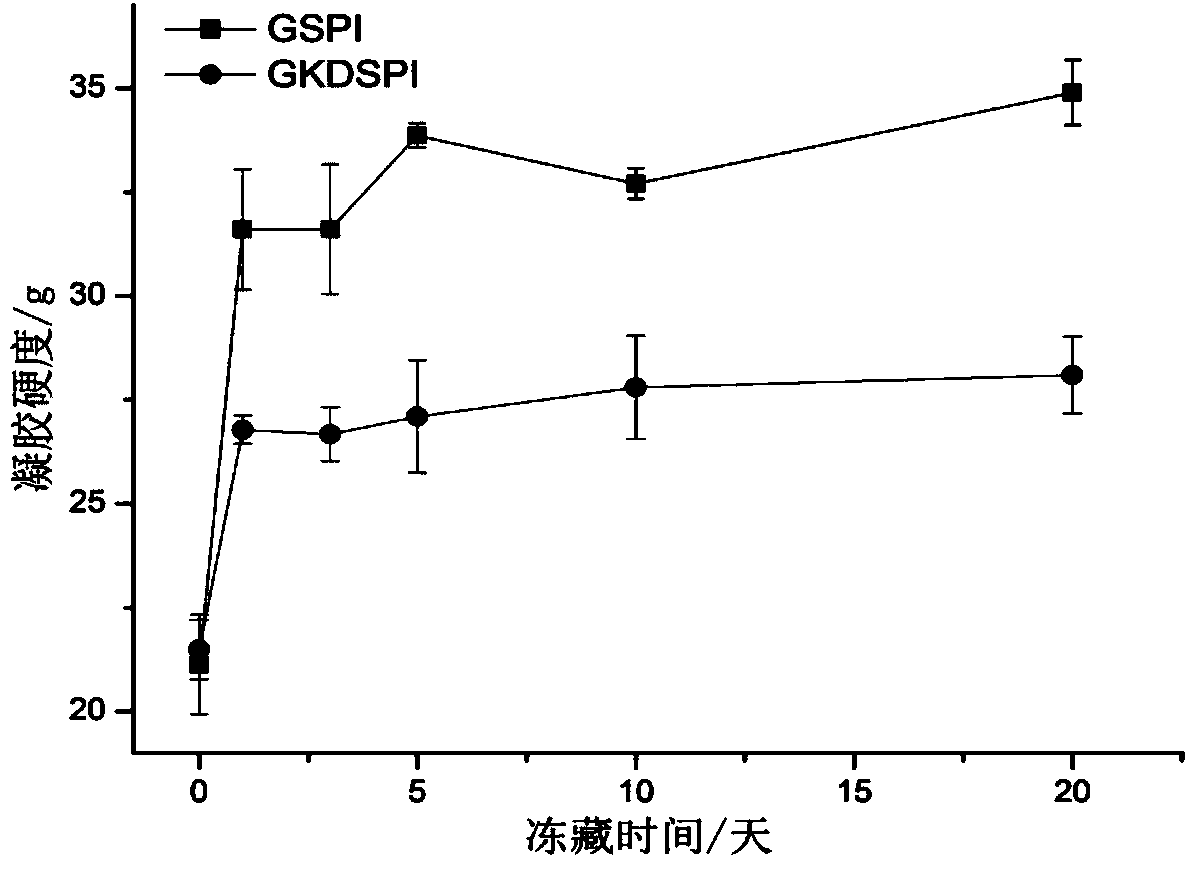

[0023] Embodiment 1 The preparation method of antifreeze soybean protein isolate

[0024] Soybeans and water were mixed according to the mass ratio of soybean meal and water of 1:15, and stirred at 50°C and pH 8.0 for 1.5h. Then filter the soybean meal aqueous solution with gauze, centrifuge the filtrate at 4000rpm for 20min, discard the precipitate, adjust the pH of the supernatant to 4.5 and let it settle for 30min, collect the precipitate by centrifugation and add water to redissolve to pH7.0. According to the mass ratio of pig bone gelatin and soybean protein isolate, gelatin is added to the soybean protein isolate solution in an amount of 1:10, after stirring evenly, transglutaminase is added in a ratio of 1:500 by enzyme to protein weight ratio, stirred and mixed After homogenization, react at 50°C for 2 hours; after the reaction stops, inactivate the enzyme in a boiling water bath for 5 minutes, adjust the acid, let it stand, and centrifuge to collect the protein precip...

Embodiment 2

[0025] Example 2 The preparation method of antifreeze soybean protein isolate

[0026] Soybeans and water were mixed according to the mass ratio of soybean meal and water of 1:15, and stirred at 50°C and pH 8.0 for 1.5h. Then filter the soybean meal aqueous solution with gauze, centrifuge the filtrate at 4000rpm for 20min, discard the precipitate, adjust the pH of the supernatant to 4.5 and let it settle for 30min, collect the precipitate by centrifugation and add water to redissolve to pH7.0. According to the mass ratio of fish scale gelatin and soybean protein isolate of 1:8, add gelatin to soybean protein isolate solution, stir well, add transglutaminase according to the ratio of enzyme to protein weight ratio of 1:600, stir and mix well Afterwards, react at 50°C for 2 hours; after the reaction stops, inactivate the enzyme in a boiling water bath for 5 minutes, adjust the acidity, let it stand, and centrifuge to collect the protein precipitate. The precipitate is redissolv...

Embodiment 3

[0027] Example 3 The preparation method of antifreeze soybean protein isolate

[0028] Soybeans and water were mixed according to the mass ratio of soybean meal and water of 1:15, and stirred at 50°C and pH 8.0 for 1.5h. Then filter the soybean meal aqueous solution with gauze, centrifuge the filtrate at 4000rpm for 20min, discard the precipitate, adjust the pH of the supernatant to 4.5 and let it settle for 30min, collect the precipitate by centrifugation and add water to redissolve to pH7.0. According to the mass ratio of fish skin gelatin and soybean protein isolate, gelatin is added to the soybean protein isolate solution in an amount of 1:15, after stirring evenly, transglutaminase is added in a ratio of 1:700 by enzyme to protein weight ratio, and stirred After homogenization, react at 40°C for 3 hours; after the reaction stops, inactivate the enzyme in a boiling water bath for 5 minutes, adjust the acid, let it stand, and centrifuge to collect the protein precipitate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com