Solar cell, method for manufacturing solar cell, and solar cell module

A solar cell and manufacturing method technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as complicated processes, and achieve the effects of easy electrode formation and excellent photoelectric conversion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

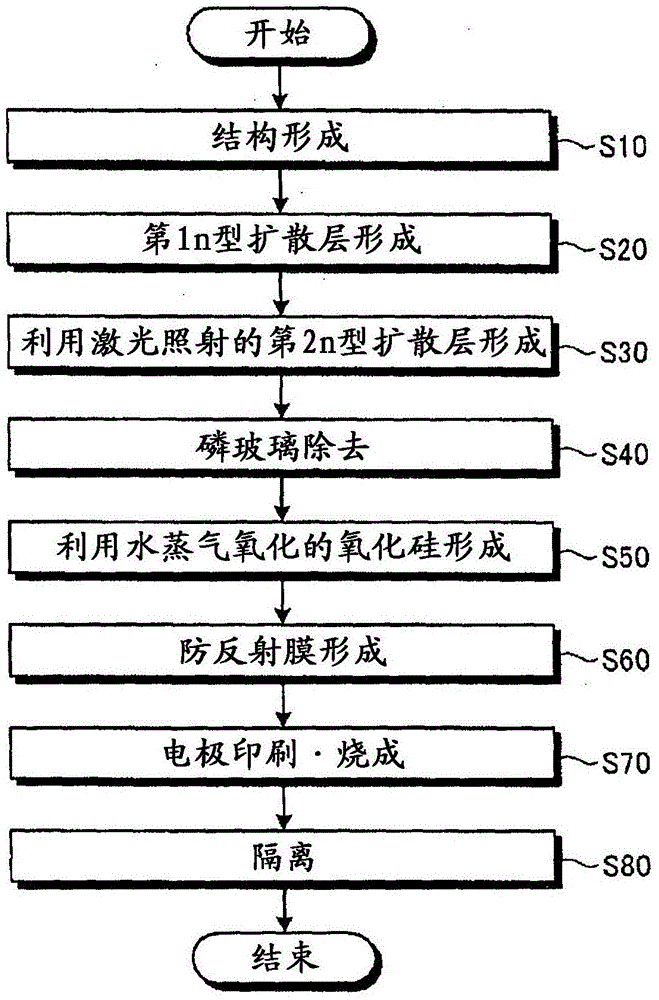

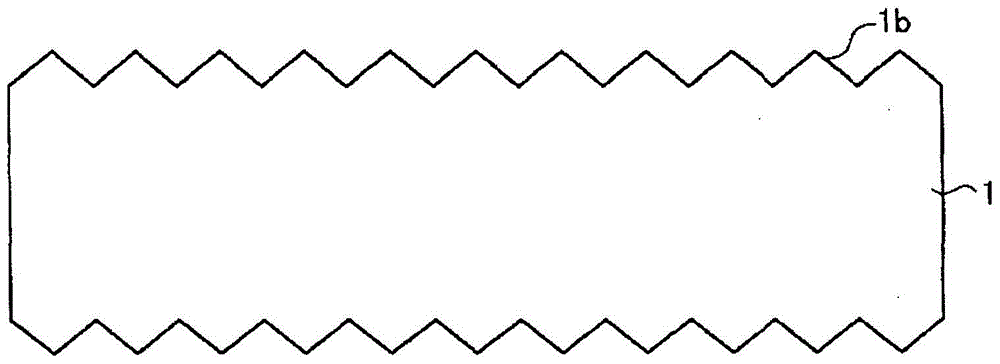

[0038] figure 1 It is a flowchart for explaining an example of the manufacturing process of the solar battery cell concerning Embodiment 1 of this invention. Figure 2-1~Figure 2-9 It is a main part cross-sectional view for demonstrating an example of the manufacturing process of the solar battery cell concerning Embodiment 1 of this invention. image 3 It is a main part perspective view showing the schematic structure of the solar battery cell concerning Embodiment 1 produced by the manufacturing method of the solar cell cell concerning Embodiment 1. Be clarified, although in figure 1 It is not described in the following description, but the immersion treatment in hydrofluoric acid and the water washing treatment for the purpose of wafer cleaning treatment and natural oxide film removal are performed as necessary between each process.

[0039] First, as a semiconductor substrate, for example, a p-type single crystal silicon substrate (hereinafter, referred to as a p-type silicon ...

Embodiment approach 2

[0092] Figure 8 It is a flowchart for explaining an example of the manufacturing process of the solar battery cell concerning Embodiment 2 of this invention. Although the case where phosphor glass is removed after laser irradiation is described in Embodiment 1, the order of laser irradiation and phosphor glass removal is not limited to this. The order of laser irradiation and phosphor glass removal may be reversed, that is, laser irradiation is performed after the phosphor glass is removed.

[0093] Phosphorus oxychloride (POCl 3 ) After the thermal diffusion of the gas, the (inactive) phosphorus (P) that has not been electrically activated exists on the surface of the silicon substrate. If laser irradiation is performed in this state, the inactive phosphor (P) is activated by the laser irradiation, and the activated phosphor (P) diffuses to a deeper area of the silicon substrate to form an SE structure. Thereafter, if water vapor oxidation or pyrolytic oxidation is performed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com