A pneumatic in-mold riveting device

An in-mold riveting and pneumatic technology, which is applied in the field of pneumatic in-mold riveting devices, can solve the problems of increasing costs and rising product prices, and achieves the effects of cost saving, product price reduction and overall structural reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

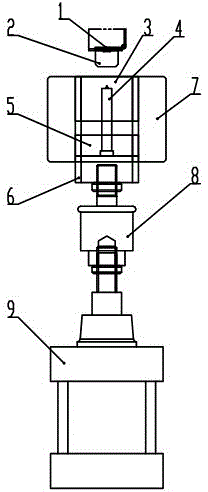

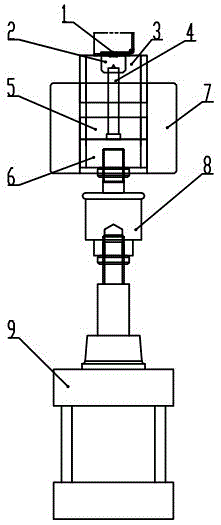

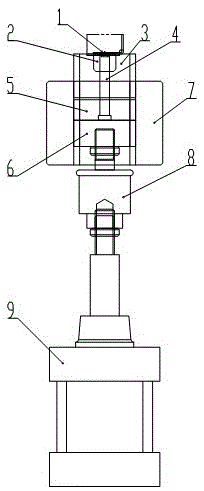

[0016] Such as Figure 1~3 The pneumatic in-mold riveting device shown includes a driving assembly, which is different in that: a backing plate 6 is connected to the driving assembly used in the present invention. Specifically, a fixing plate 5 is connected to the backing plate 6 , and a riveting punch 4 is connected to the fixing plate 5 . At the same time, a stripper 3 is connected to the riveting punch 4 , and a bending punch 2 is distributed above the stripper 3 . Moreover, riveting working ends 1 are distributed on the bending punch 2 .

[0017] As far as a preferred embodiment of the present invention is concerned, a floating coupling 8 is installed between the driving assembly and the backing plate 6 . Simultaneously, in order to improve the working efficiency of driving, the driving assembly is an air cylinder 9 . Of course, in order to assist in positioning the installation position of the riveting punch 4 , a fixing plate 5 is provided on the backing plate 6 . Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com