High-density connector with long plugging service life

A high-density connector and long-life technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problem of reduced service life of plugs and sockets, loosening and separation of plugs and sockets, and reduced stability of plugs and sockets and other problems, to achieve the effect of reducing the riveting process, ensuring interchangeability and safety, and superior electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

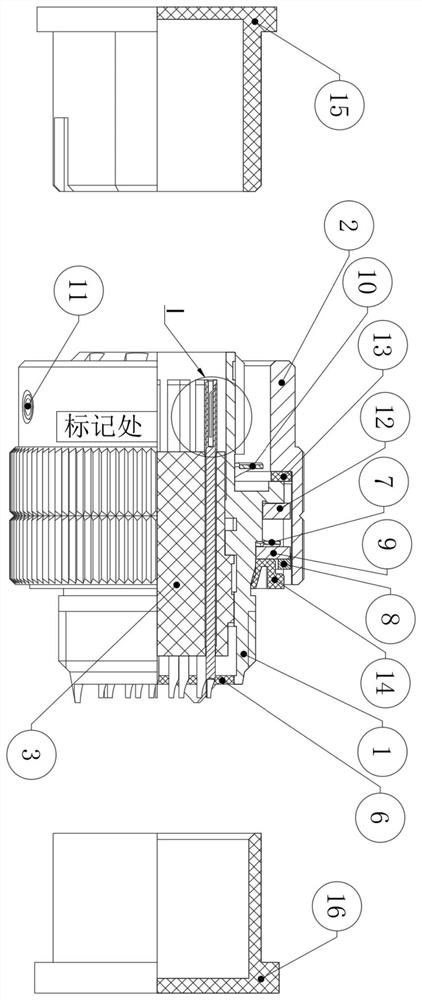

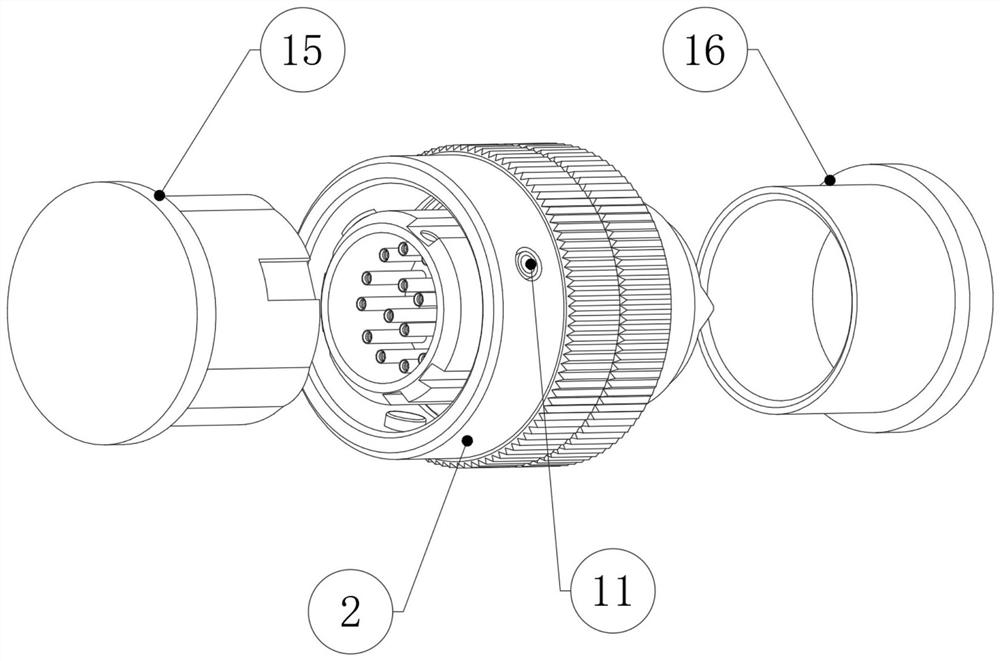

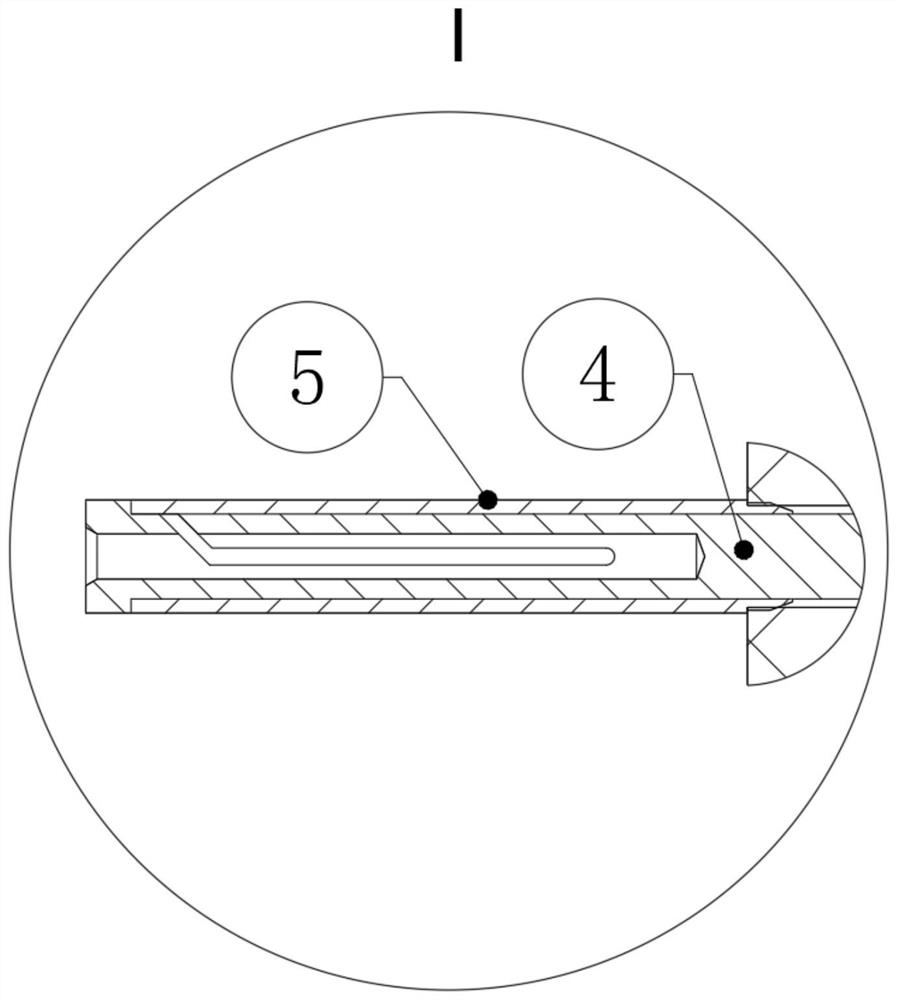

[0037] see Figure 1-5 , an embodiment provided by the present invention: a high-density connector with high plug-in life, including a plug and a socket, the plug includes a splined housing 1, a connecting nut 2, a short circular insulator 3, a jack 4, Sheath 5, first number plate 6, corrugated spring 7, retaining ring 8, three-key retaining ring 9, grounding spring 10, staple 11, locking washer 12, insulating washer 13, collar 14, plug dustproof cap 15 1. The first dustproof cap 16, the connecting nut 2 is threadedly connected to one end of the spline housing 1, the ground spring 10 is fixedly connected to the inside of the connecting nut 2, and the insulating washer 13 is fixedly installed on the connecting nut 2 and the spline housing Between the body 1, the locking washer 12 is fixedly connected to the inner side of the insulating washer 13, the three-key retaining ring 9 is fixedly installed inside the spline housing 1 through the corrugated spring 7, and the retaining ri...

Embodiment 2

[0050] On the basis of Example 1, such as Figure 6-10 As shown, the socket dustproof cap 23 includes a sealing cover 25 and a protective connecting ring 26, and the upper end of the protective connecting ring 26 is threadedly inserted into the inside of the sealing cover 25, and the inside of the sealing cover 25 is fixedly equipped with a miniature heat dissipation fan 27. The square disc housing 17 is slidably engaged inside the square disc rubber pad 21 by rotating the snap ring 29, and the bottom end of the rear-mounted square disc housing 17 is fixedly installed with a reset plate 30, and the bottom end of the square disc rubber pad 21 is fixedly installed There is an auxiliary baffle plate 28, and a return spring 31 is fixedly installed between the auxiliary baffle plate 28 and the reset plate 30. The auxiliary baffle plate 28 and the reset plate 30 are all arranged in a hexagonal column shape, and there are six return springs 31. Square rubber pads The interior of 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com