Method for manufacturing jellyroll-type electrode assembly and method for manufacturing jellyroll-type polymer secondary battery

一种电极组件、电极单元的技术,应用在聚合物二次电池领域,能够解决难以实现期望形状、不易切割成具有预定形状等问题,达到提高设计灵活性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Exemplary embodiments of the present disclosure will now be described in detail with reference to the accompanying drawings.

[0024] This disclosure, however, may be illustrated in many different forms and should not be construed as limited to the specific embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the disclosure to those skilled in the art.

[0025] In the drawings, the shapes and dimensions of elements may be exaggerated for clarity, and the same reference numerals will be used throughout to designate the same or like elements.

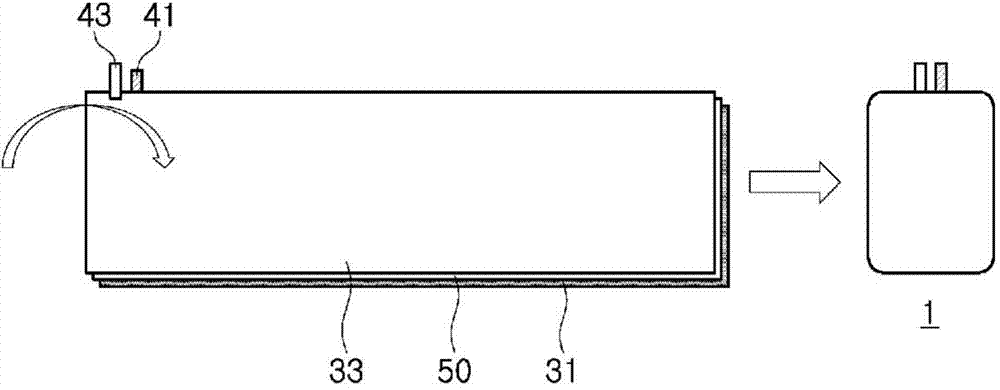

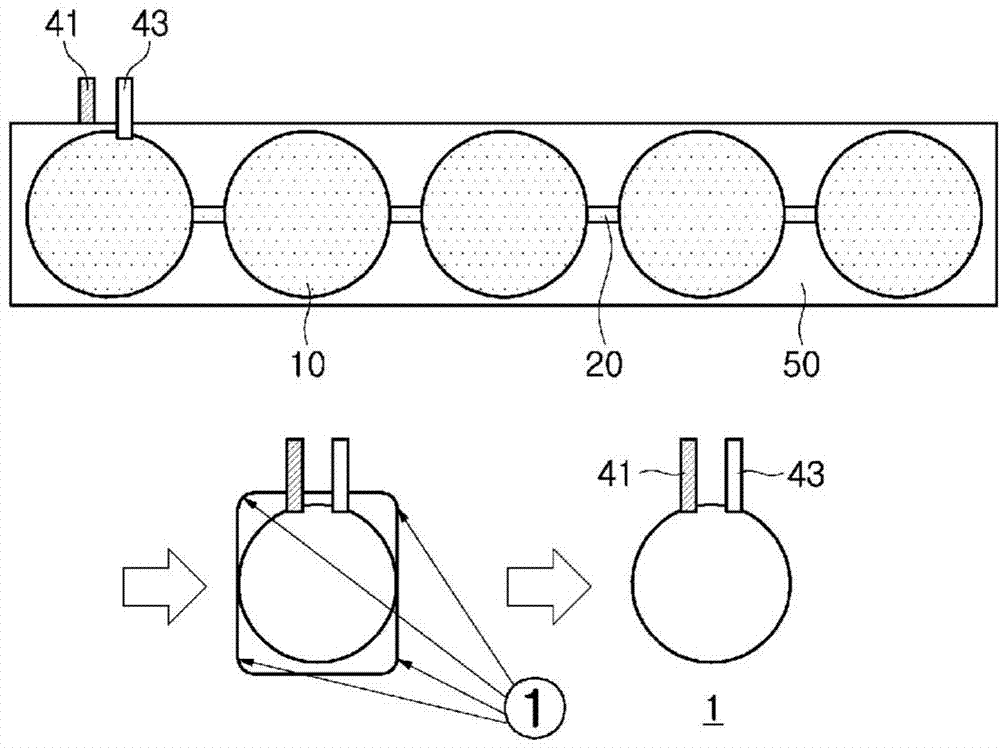

[0026] The present disclosure relates to a method of manufacturing a jelly-roll electrode assembly. Here, the inventors have found that the design flexibility of the battery can be improved because, in the manufacture of the jelly-roll electrode assembly, by cutting the shape of the electrode plane on which the charging / discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com