Polyamic acid solution composition and polyimide

A technology of polyamic acid and polyimide, which is applied in the field of polyamic acid solution composition, can solve the problems such as the decrease of polyimide transmittance, and achieve the effect of high transparency and excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] Hereinafter, the present invention will be described in more detail using examples. It should be noted that the present invention is not limited to the following examples.

[0088] The abbreviations of the compounds used in the following examples are as follows.

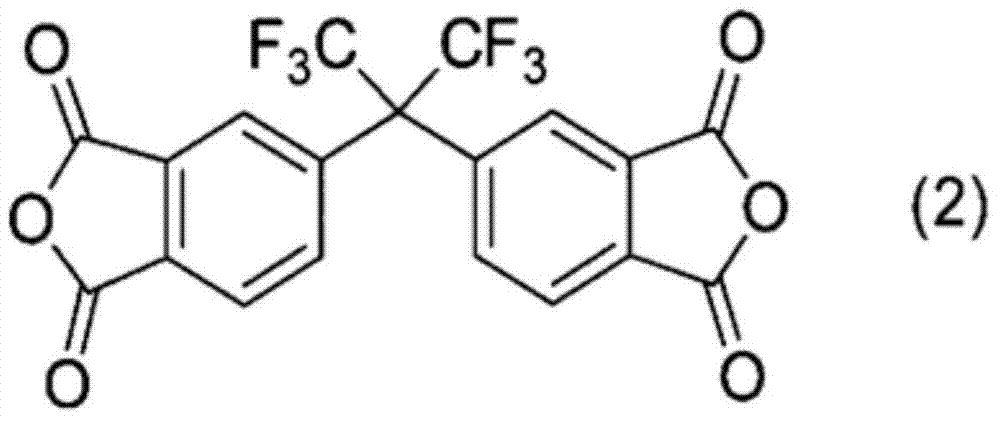

[0089] 6FDA: 2,2-bis(3,4-dicarboxyphenyl)hexafluoropropane dianhydride

[0090] 2,2'-TFMB: 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl

[0091] 6FAP: 2,2'-bis(3-amino-4-hydroxyphenyl)hexafluoropropane

[0092] The property measurement methods used in the following examples are as follows.

[0093] (solid content concentration)

[0094] The solid content concentration of the polyamic acid solution is to dry the polyamic acid solution at 350°C for 30 minutes, and use the following formula according to the weight W before drying 1 and dry weight W 2 The value obtained.

[0095] Solid content concentration (weight %)=(W 2 / W 1 )×100

[0096] (log viscosity)

[0097] The sample solution was diluted so...

reference example 1

[0104] Add 440 g of N-methyl-2-pyrrolidone as a solvent to a glass reaction vessel with a 500-ml internal volume equipped with a stirrer and a nitrogen gas introduction and discharge pipe, and add 2,2'-TFMB 25.12 g (0.0785 mol) and 6FDA34 .88g (0.0785 mol), stirred at 50°C to obtain a polyamic acid solution with a solid content concentration of 11.43% and a logarithmic viscosity of 0.60.

Embodiment 1

[0108] To the polyamic acid solution obtained in Reference Example 1 was added a colloidal solution obtained by dispersing colloidal silica in N,N-dimethylacetamide (manufactured by Nissan Chemical Industries, Ltd., DMAc-ST; silica particles Solid content concentration: 20 wt %; particle size of silicon dioxide: 10 to 20 nm) 6 g and stirred to obtain a polyamic acid solution composition. The amount of silica added was 2 parts by mass relative to 100 parts by mass of the monomer component (6FDA+2,2'-TFMB).

[0109] The polyamic acid solution composition is coated on the glass plate of the base material by a bar coater, and the coating film is heat-treated at 120°C for 60 minutes, 150°C for 30 minutes, 200°C for 30 minutes, and 400°C for 1 minute. A polyimide film with a thickness of 10 μm was formed on the plate.

[0110] Then, the polyimide film was peeled off from a glass plate, and the linear expansion coefficient and light transmittance of this polyimide film were measured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com