Pay-off rack

A pay-off stand and cross technology, applied in the field of pay-off stand, can solve the problems of material loss, the diameter of the turntable cannot be adjusted, the pay-off stand cannot meet the requirements of use, etc., to avoid material loss and increase stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

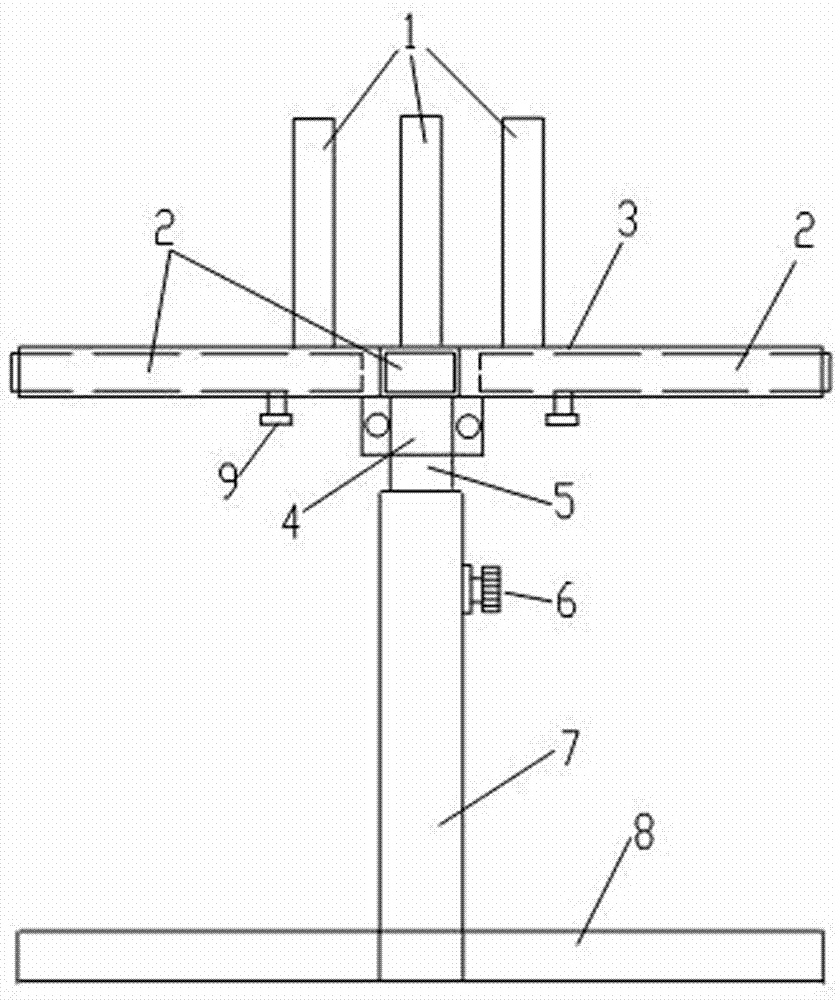

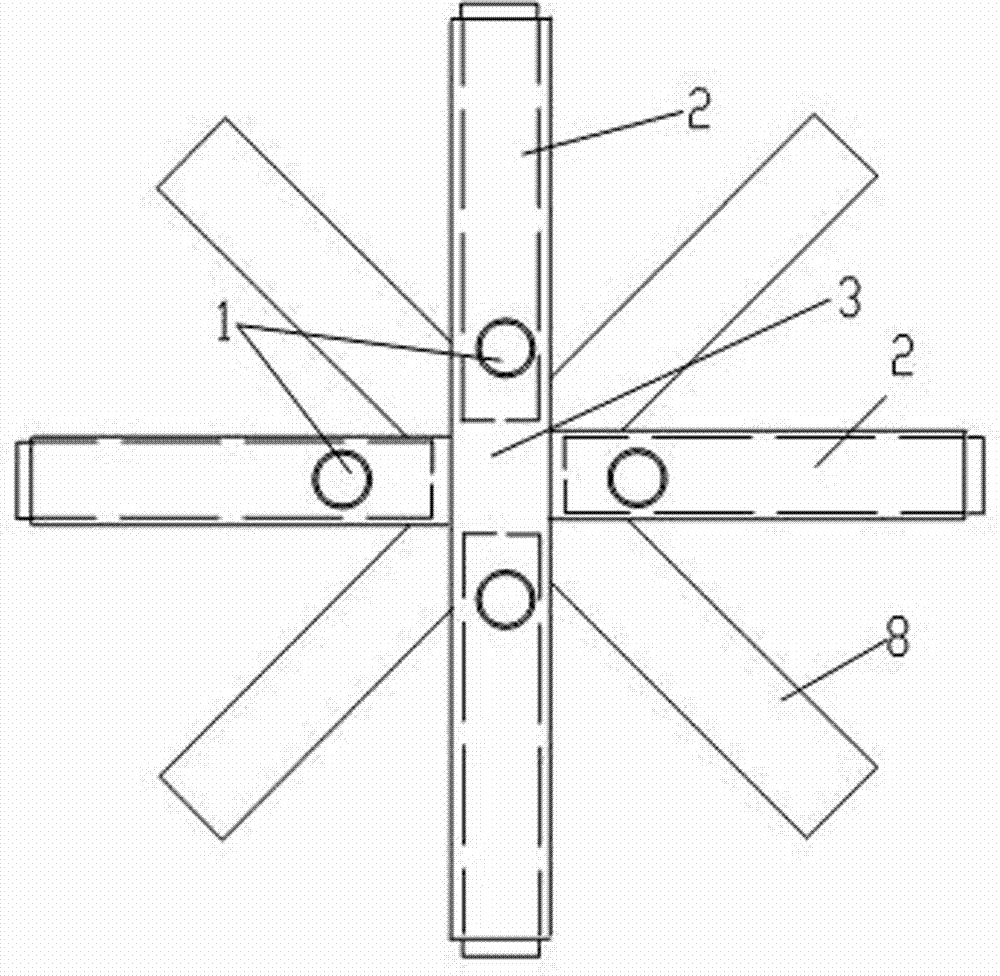

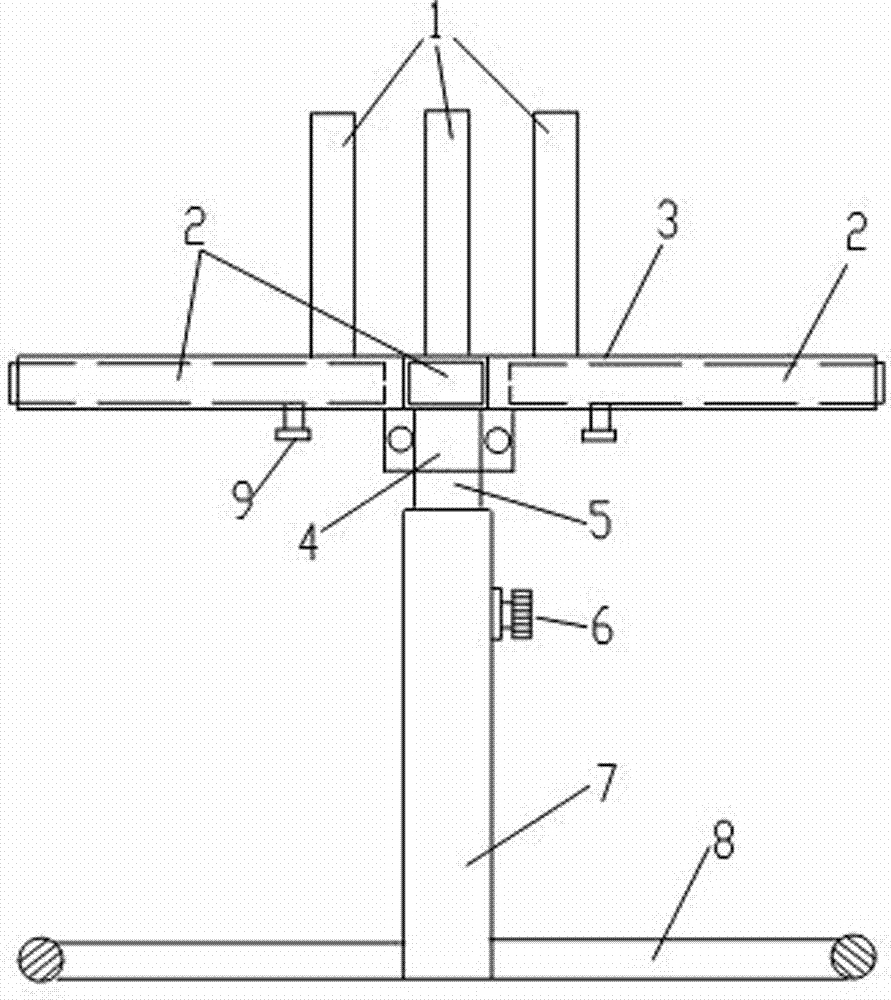

[0014] Embodiment 1: A pay-off rack, including a turntable 3, a lifting rod 5, and a vertical tube 7 with a base 8; the turntable 3 is a cross made of a pipe with a rectangular section, and is respectively set in four pipes of the cross The drawing tube 2 with a rectangular cross-section is provided with a vertical shaft tube 1 on the top surface of the cross, and the upper end of the lifting rod 5 is connected to the center of the bottom of the turntable 3 through a bearing 4, and the lower end of the lifting rod 5 is inserted into the vertical tube 7, the screw 6 that can fasten the lifting rod 5 is provided on the vertical tube 7 wall. The bottom surfaces of the four pipes of the cross are respectively provided with chute holes, and the lower part of the drawing pipe 2 is provided with fastening screws 9 which can move along the chute holes. There are four vertical shaft tubes 1 and they are evenly distributed on the top surface of the rotating disk 3 . The base 8 is a P-s...

Embodiment 2

[0015] Embodiment 2: A pay-off rack, including a turntable 3, a lifting rod 5, and a vertical tube 7 with a base 8; the turntable 3 is a cross made of a pipe with a rectangular section, and is respectively set in four pipes of the cross The drawing tube 2 with a rectangular cross-section is provided with a vertical shaft tube 1 on the top surface of the cross, and the upper end of the lifting rod 5 is connected to the center of the bottom of the turntable 3 through a bearing 4, and the lower end of the lifting rod 5 is inserted into the vertical tube 7, the screw 6 that can fasten the lifting rod 5 is provided on the vertical tube 7 wall. The bottom surfaces of the four pipes of the cross are respectively provided with chute holes, and the lower part of the drawing pipe 2 is provided with fastening screws 9 which can move along the chute holes. There are four vertical shaft tubes 1 and they are evenly distributed on the top surface of the rotating disk 3 . The base 8 is a rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com