Composite positive electrode material based on 3D graphene and preparation method thereof

A composite positive electrode material and composite material technology, which is applied in the field of positive electrode materials composited with nano-metallic nickel and three-dimensional graphene and its preparation, can solve the problems of high cost and complicated process, and achieve low cost, simple process, and reduced capacity fading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

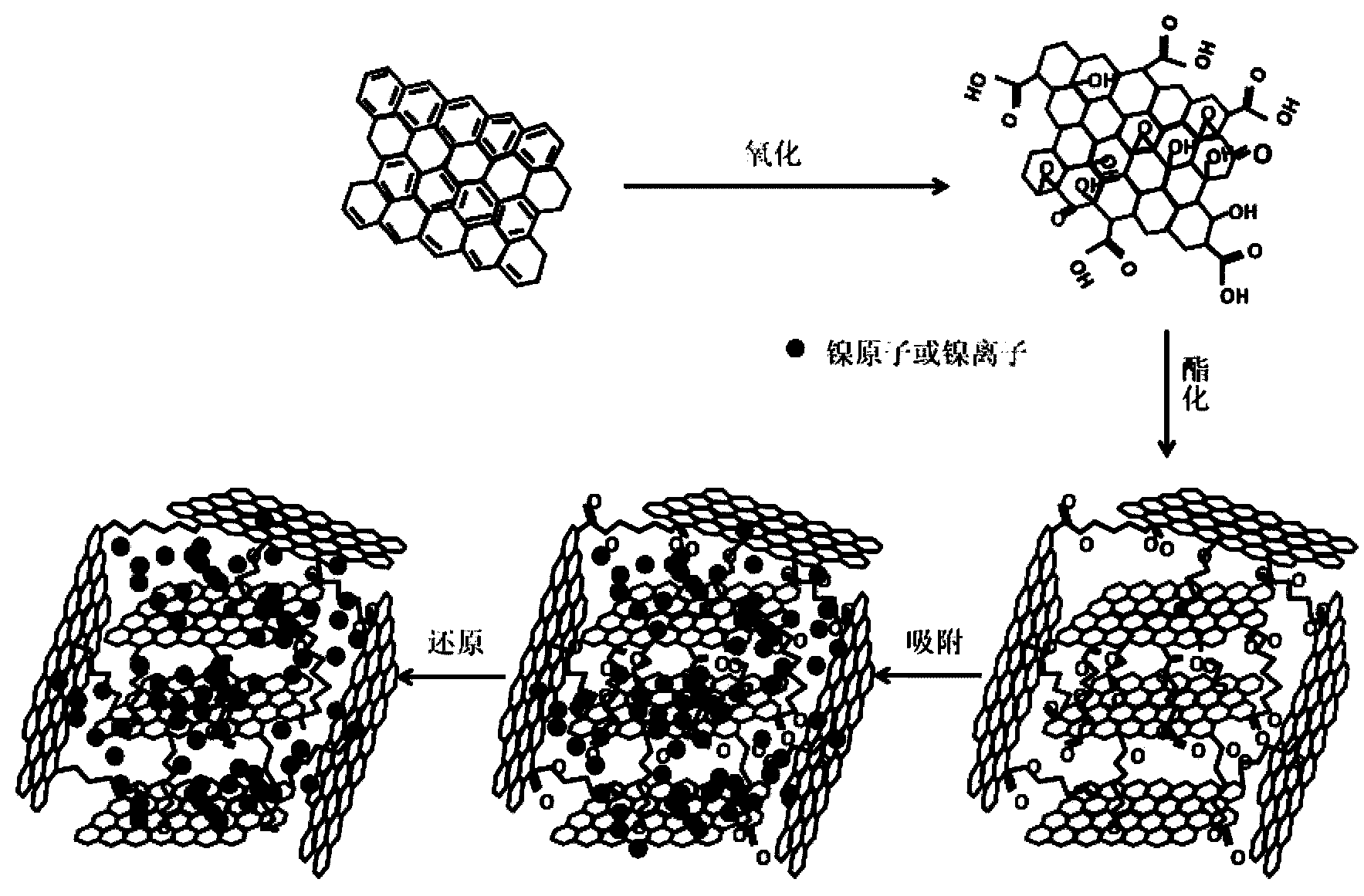

[0028] The present invention also relates to a method for preparing the above-mentioned three-dimensional graphene-based composite positive electrode material. figure 1Show the composite process schematic diagram of three-dimensional graphene of the present invention and nano metal nickel, refer to figure 1 , the preparation method of the present invention comprises: graphene is oxidized to graphene oxide; Make graphene oxide and have at least two bridging organic matter that can react with the oxygen-containing group on described graphene oxide and / or esterification to form a three-dimensional structure by bridging each other; adsorbing metal nickel salt in the three-dimensional structure; and reducing it to prepare a three-dimensional graphene-based composite positive electrode material.

[0029] More specifically, the present invention may include the following steps:

[0030] (1) adding natural graphite into water, after ultrasonic dispersion, after continuing to stir fo...

Embodiment 1

[0057] Put 6g of natural graphite powder into 1000mL water, after ultrasonication for 2 hours, and then magnetically stir for 2 hours, place the resulting mixed solution in a microwave reaction vessel and heat at 100°C for 10 minutes, then add excess ethylene glycol and an appropriate amount of concentrated sulfuric acid to adjust the pH to 5-7 In between, heat in a 70°C oil bath while stirring until the liquid becomes viscous, then cool to room temperature. Add 50mL of 0.05M nickel oxalate solution in ethylene glycol dropwise, continue to stir for 24h, and then freeze-dry. Three-dimensional graphene and nano-nickel metal composites were obtained after treatment at 350 °C for 2 h in a hydrogen atmosphere.

Embodiment 2

[0059] Put 6g of natural graphite powder into 1000mL water, after ultrasonication for 2 hours, and then magnetically stir for 2 hours, place the resulting mixed solution in a microwave reaction vessel and heat at 100°C for 10 minutes, then add excess ethylene glycol and an appropriate amount of concentrated sulfuric acid to adjust the pH to 5-7 In between, heat in a 70°C oil bath while stirring until the liquid becomes viscous, then cool to room temperature. Add 100mL of 0.05M nickel oxalate solution in ethylene glycol dropwise, continue to stir for 24h, and then freeze-dry. Three-dimensional graphene and nano-nickel metal composites were obtained after treatment at 350 °C for 2 h in a hydrogen atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com