Transparent flexible supercapacitor fabric and preparation method thereof

A supercapacitor and fabric technology, applied in the field of energy storage devices, can solve the problems of opaque electrodes, thick fabric electrodes, general electrical conductivity, etc., and achieve the effect of good transparency and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

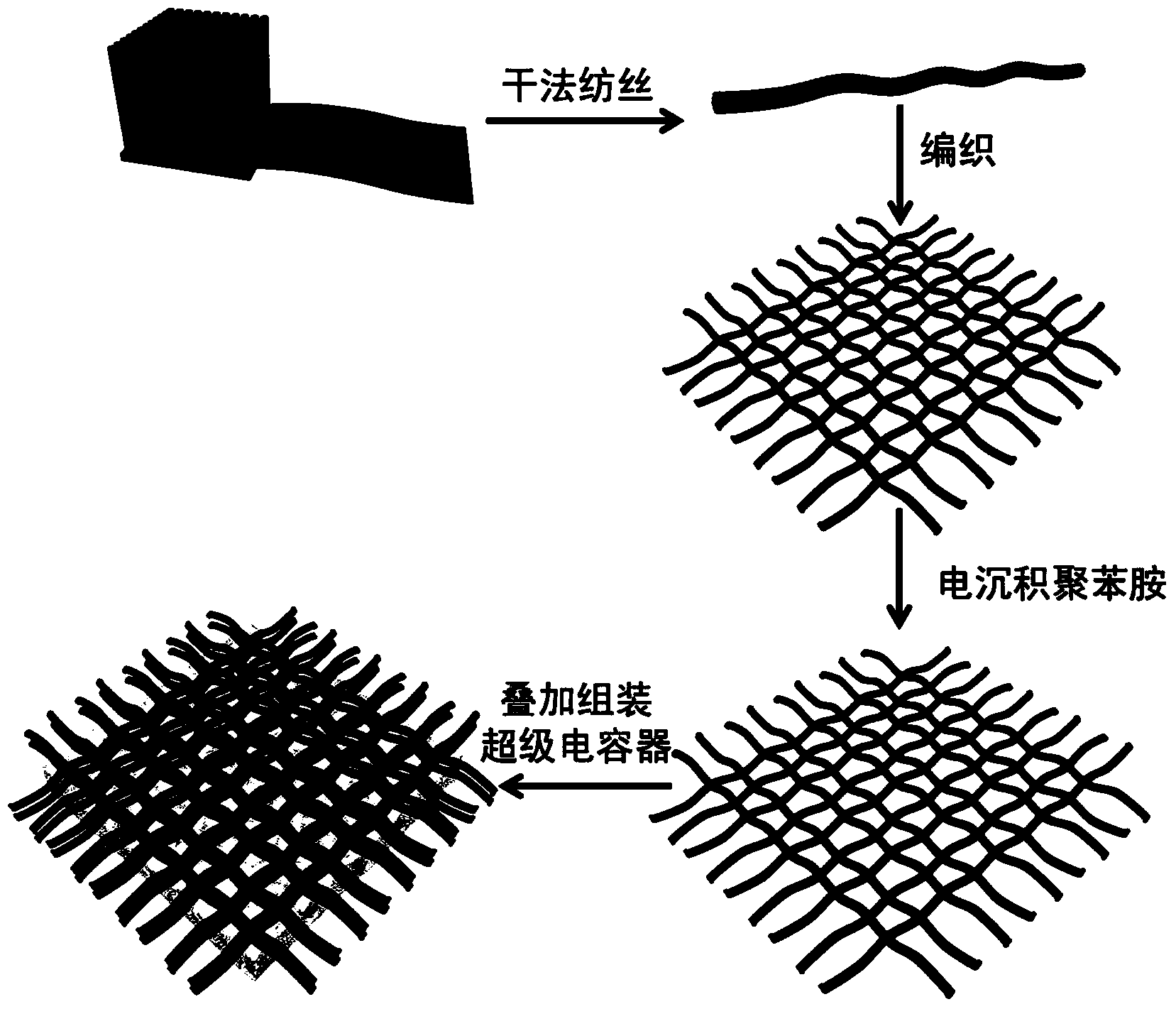

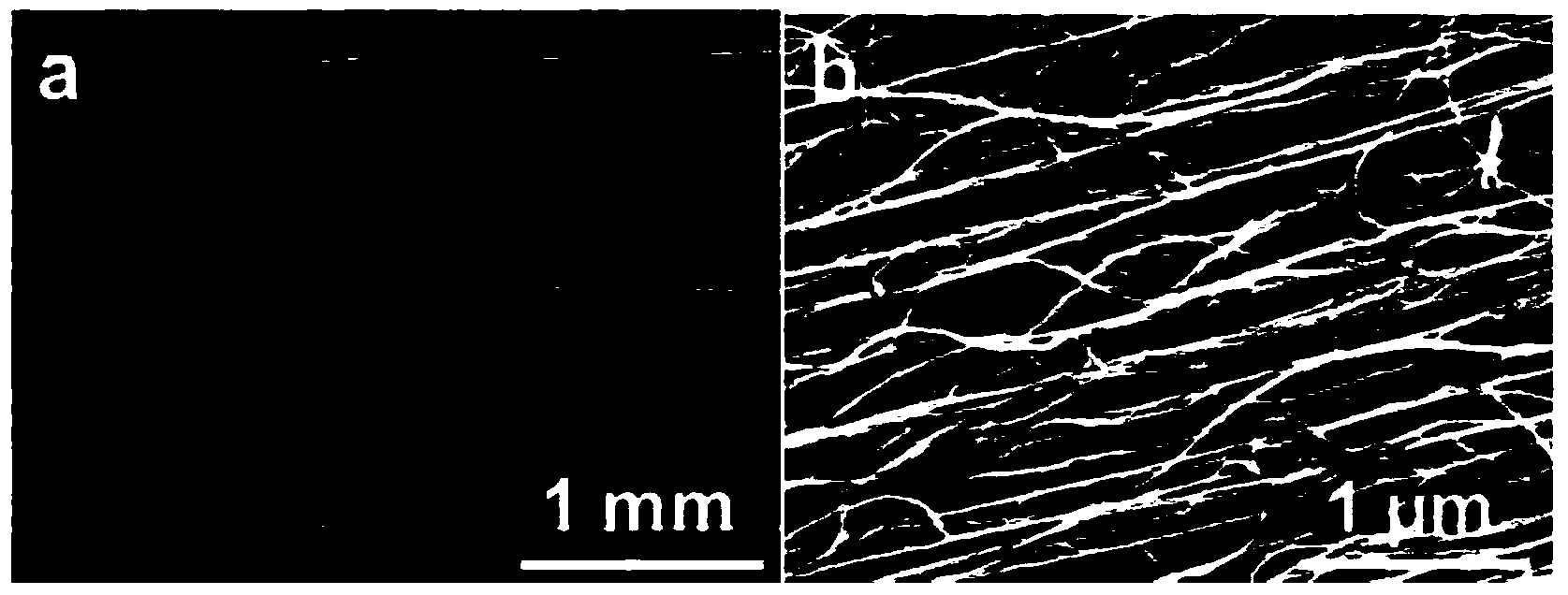

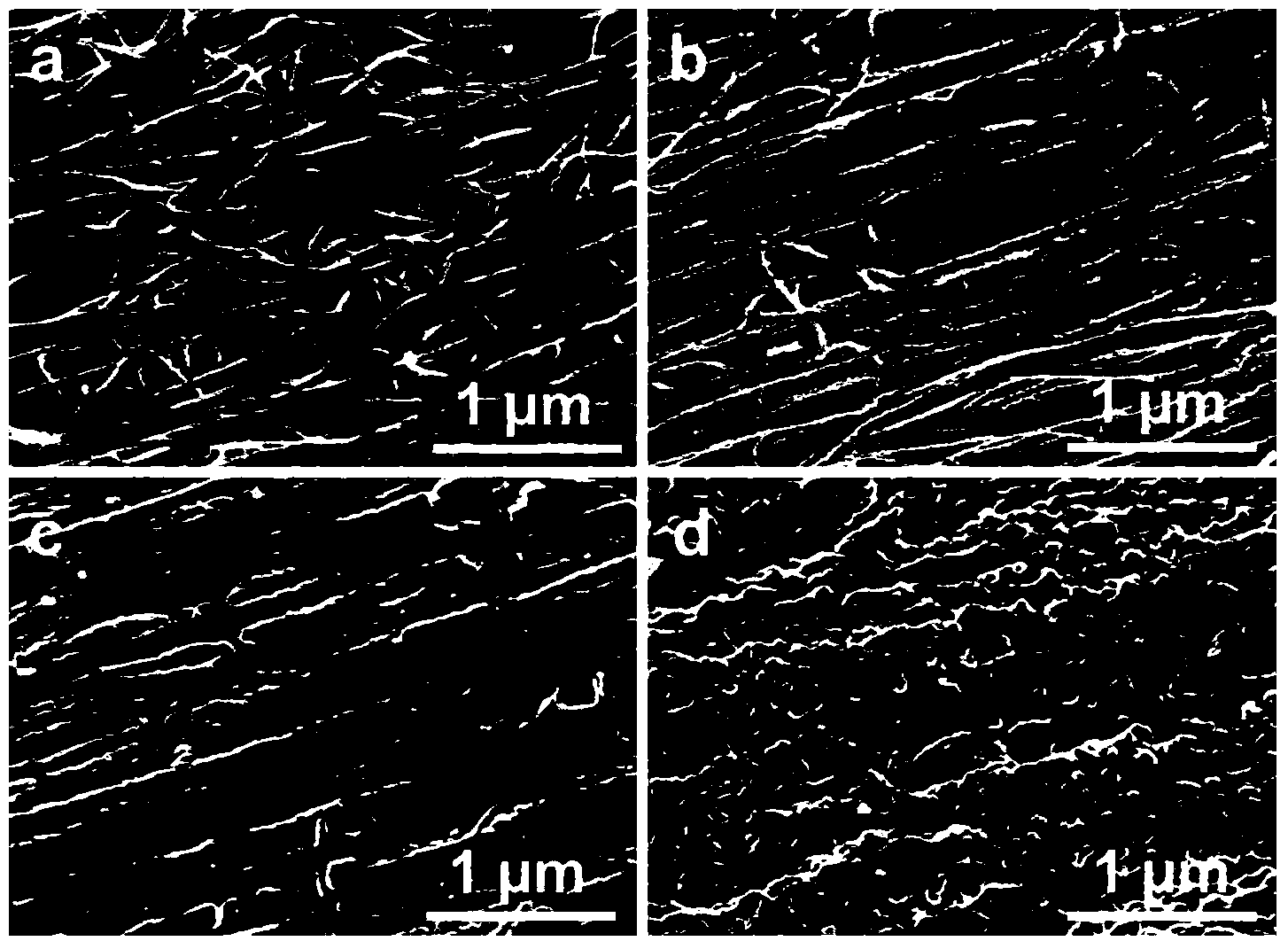

[0035] Oriented carbon nanotube fibers are prepared according to the prior art, that is, carbon nanotube arrays are prepared by so-called chemical vapor deposition, and then corresponding fibers are prepared by dry spinning. Specifically, in a quartz tube furnace, the Fe (1.2 nm) / Al 2 o 3 (3 nm) silicon wafer as catalyst, ethylene gas as carbon source, Ar and H 2 The mixed gas is used as the carrier gas, and the temperature is raised to 740 o C, carbon nanotubes start to grow, and the growth time is controlled at 10-20 min. After obtaining the spinnable carbon nanotube array, use a blade to pull out the carbon nanotube film from the edge of the carbon nanotube array, superimpose 5-15 layers of carbon nanotube film, and then use a motor to rotate and twist at a speed of 1000 rpm to obtain a carbon nanotube film. Nanotube fibers, and finally carbon nanotube fibers are woven into fabrics.

[0036] The polyaniline in the fabric electrode material was prepared by electrodeposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com