Thin-film transistor, active matrix organic light-emitting diode assembly, and manufacturing method thereof

A technology of light-emitting diodes and thin-film transistors, which is applied in the direction of transistors, semiconductor devices, and electric solid-state devices. It can solve problems affecting the stability of OLEDs and changes in the voltage of storage capacitors, so as to avoid unstable or even failure of component operation and improve leakage current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

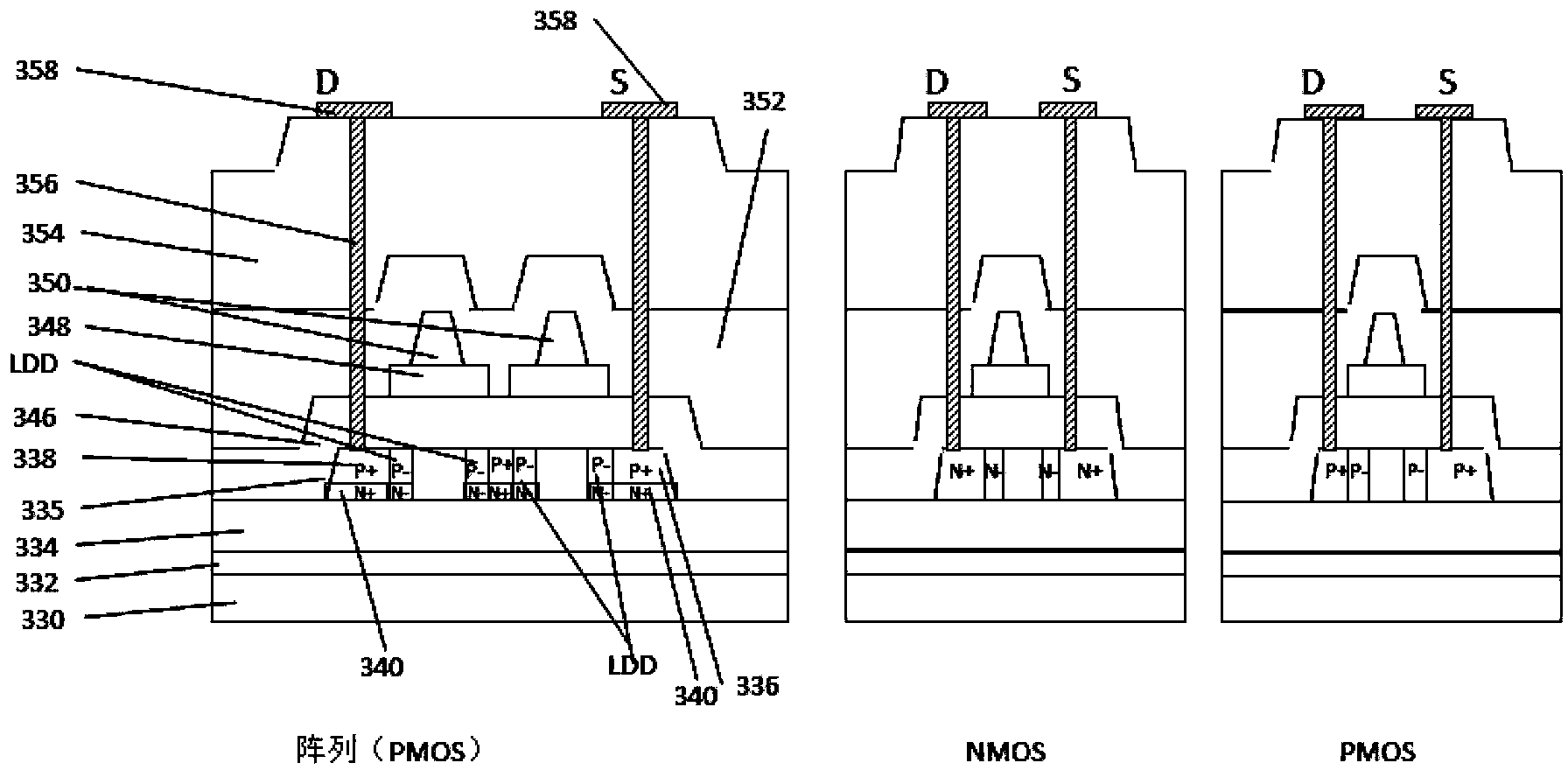

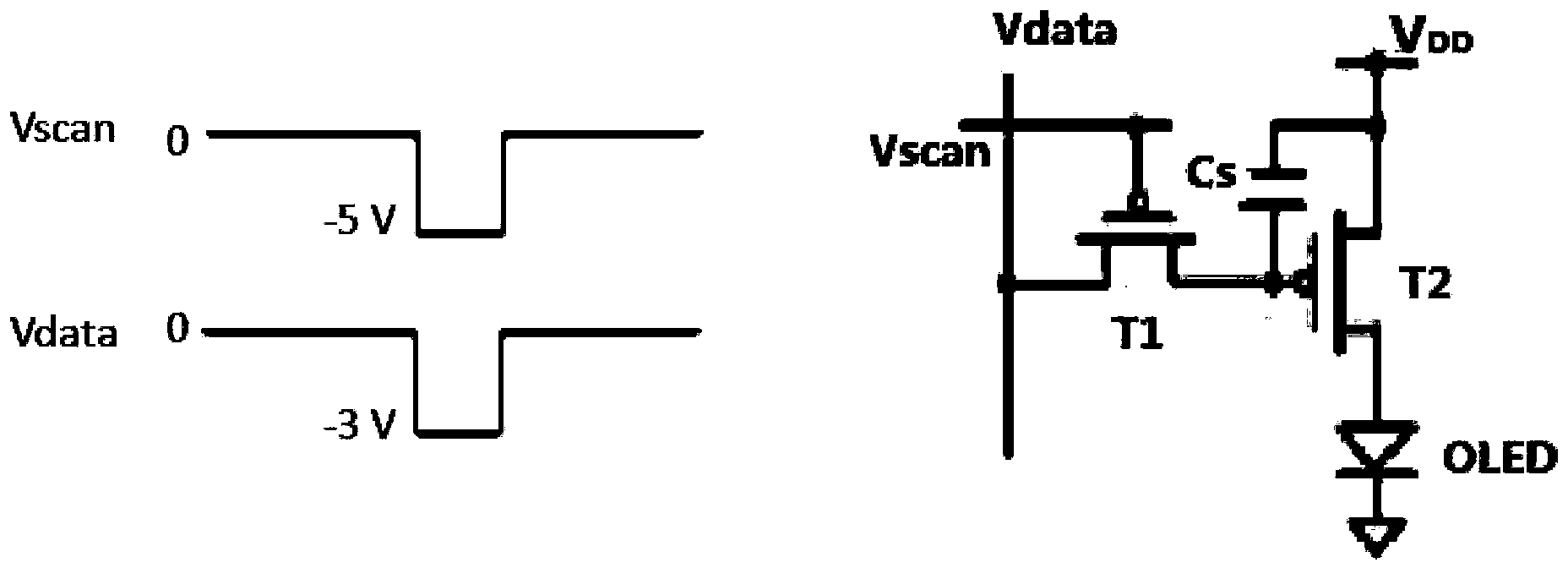

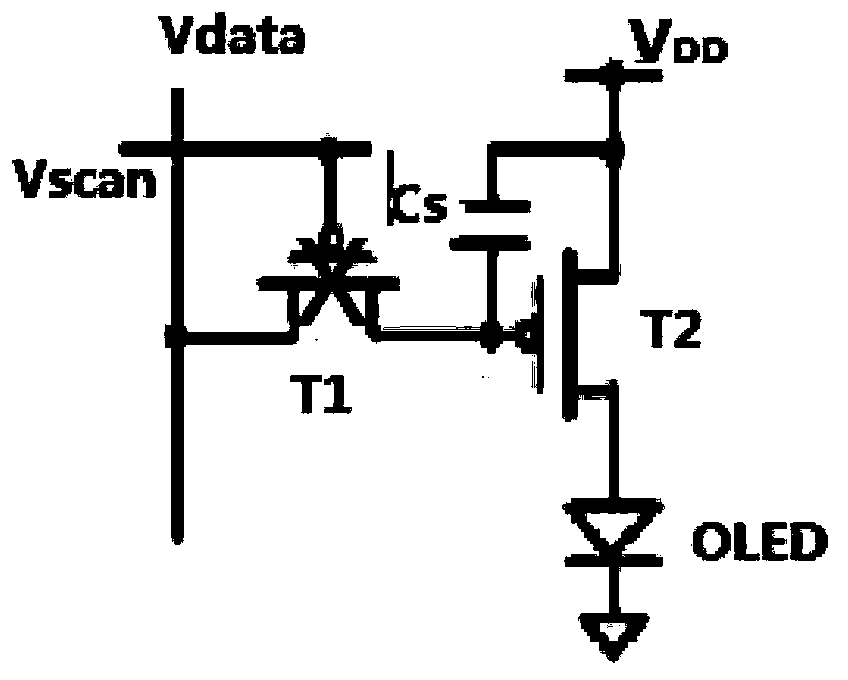

[0091] According to an exemplary embodiment, when the array substrate uses PMOS TFTs as switching elements, a P-N junction structure is formed in which the P+ region is on the upper layer and the N+ region is on the lower layer. It is easy to understand that when the array substrate uses NMOS TFTs as switching elements, the corresponding P-N junction structure can be formed, with the N+ region on the upper layer and the P+ region on the lower layer. In this way, the required depletion region structure can be obtained under the corresponding operating voltage.

[0092] According to the technical solution of the present disclosure, the leakage current of the switching thin film transistor in the AMOLED array substrate can be further improved, and the component operation instability or even failure caused by excessive leakage current can be avoided, thereby affecting the image quality of the display. It is easy to understand that the technical solutions according to the present d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com