Full-automatic single-ended and double-ended tangent wire stripping terminal pressure welding machine control system

A terminal crimping machine, wire cutting and stripping technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of limited precision and speed, unstable motor control, high cost, etc., to improve stability, facilitate maintenance and management, reduce The effect of defective production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0028] The industrial computer takes Intel compatible CPU and Windows XP operating system as the core, and is used to run the automatic single- and double-ended wire cutting and stripping terminal crimping machine control system (graphical human-computer interaction GUI) operation control software, with parameter setting and real-time online detection And processing status monitoring, database management and a variety of process operation modes.

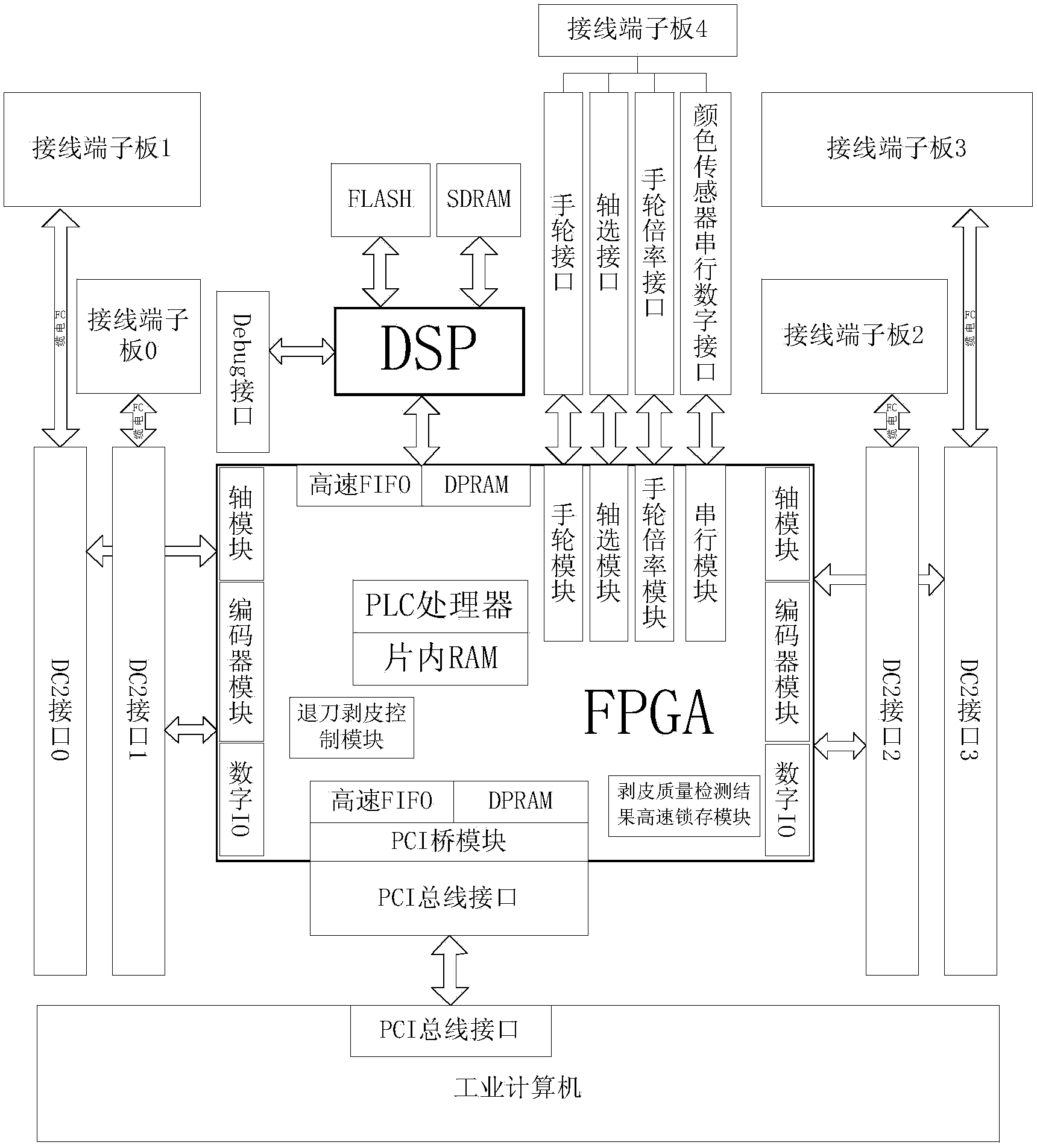

[0029] The high-performance 32-bit PCI interface of the PLC+MC integrated controller complies with the Rev2.2 PCI standard, with a bandwidth of 33MHz, supports plug-and-play, and performs control command transmission and data exchange with the industrial computer through the PCI interface bus. The controller takes DSP chip and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com