Preparation method and application of Mn-doped ZnS quantum dot imprinted sensor

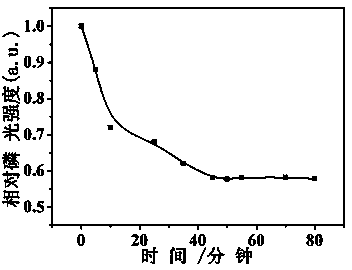

A quantum dot and sensor technology, applied in the field of environmental functional material preparation, can solve the problems of lack of universality and selectivity, low sensitivity, large workload, etc., and achieve the effects of improved sensitivity and selectivity, and good optical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

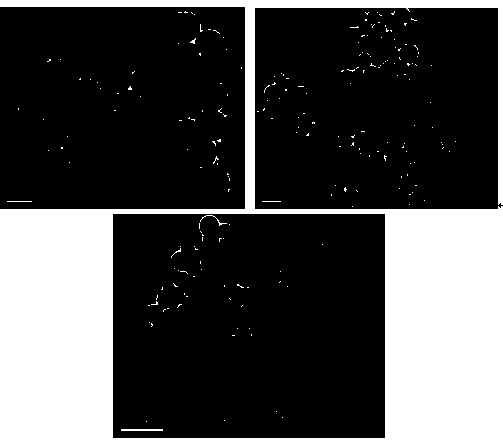

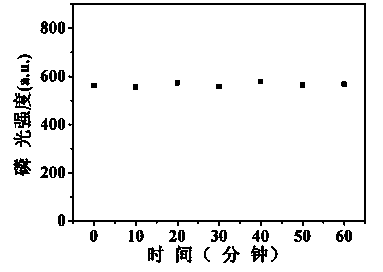

Image

Examples

Embodiment 1

[0031] (1) In a 100 mL three-neck flask, add 1.797 g ZnSO 4 ·7H 2 O, 0.059 g MnCl 2 4H 2 O, 20 mL of distilled water, the resulting mixed solution was stirred at room temperature for 15 min under nitrogen, then 5 mL of 1.501 g Na 2 S·9H 2 O in water and stirred for 18 hours. Centrifuge to obtain Mn-doped ZnS quantum dots, wash with ethanol, and dry for later use. Then 1 g of the Mn-ZnS quantum dots prepared above was dispersed in 45 mL of toluene solution, and 1 mL of 3-(methacryloyloxy)propyltrimethoxysilane (KH570) was added dropwise under continuous stirring, and the temperature was raised to 90 o C reflux for 20 hours. Centrifuge to obtain KH570-modified Mn-doped ZnS quantum dots, wash with absolute ethanol, and dry for later use.

[0032] (2) In a 100 mL round bottom flask, add 55 mL solvent acetonitrile, followed by 0.1 mmol 2,6-dichlorophenol, 0.4 mmol MAA, 50 mg KH570 modified Mn-ZnS quantum dots, 1.2 mmol EDGMA, 10 mg AIBN is ultrasonically dissolved, sealed ...

Embodiment 2

[0035] (1) In a 100 mL three-neck flask, add 1.797 g ZnSO 4 ·7H 2 O, 0.118 g MnCl 2 4H 2 O, 20 mL of distilled water, the resulting mixed solution was stirred at room temperature for 30 min under nitrogen, then added 5 mL containing 1.501 g Na 2 S·9H 2 O in water and stirred for 24 hours. Centrifuge to obtain Mn-doped ZnS quantum dots, wash with ethanol, and dry for later use. Then 1 g of the Mn-ZnS quantum dots prepared above was dispersed in 55 mL of toluene solution, and 3 mL of 3-(methacryloyloxy)propyltrimethoxysilane (KH570) was added dropwise under continuous stirring, and the temperature was raised to 90 o C reflux for 24 hours. Centrifuge to obtain KH570-modified Mn-doped ZnS quantum dots, wash with absolute ethanol, and dry for later use.

[0036] (2) In a 100 mL round bottom flask, add 65 mL solvent acetonitrile, followed by 0.1 mmol 2,6-dichlorophenol, 0.8 mmol MAA, 200 mg KH570 modified Mn-ZnS quantum dots, 2.0 mmol EDGMA, 20 mg AIBN is ultrasonically dis...

Embodiment 3

[0039] (1) In a 100 mL three-neck flask, add 1.797 g ZnSO 4 ·7H 2 O, 0.1 g MnCl 2 4H 2 O, 20 mL of distilled water, the resulting mixed solution was stirred at room temperature for 20 min under nitrogen, then 5 mL of 1.501 g Na 2 S·9H 2 O in water, stirred for 20 hours. Centrifuge to obtain Mn-doped ZnS quantum dots, wash with absolute ethanol, and dry for later use. Then 1 g of the Mn-ZnS quantum dots prepared above was dispersed in 50 mL of toluene solution, and 2 mL of 3-(methacryloyloxy)propyltrimethoxysilane (KH570) was added dropwise under continuous stirring, and the temperature was raised to 90 o C reflux for 22 hours. Centrifuge to obtain KH570-modified Mn-doped ZnS quantum dots, wash with absolute ethanol, and dry for later use.

[0040] (2) In a 100 mL round bottom flask, add 60 mL solvent acetonitrile, followed by 0.1 mmol 2,6-dichlorophenol, 0.6 mmol MAA, 100 mg KH570 modified Mn-ZnS quantum dots, 1.6 mmol EDGMA, 15 mg AIBN is ultrasonically dissolved, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com