Friction load coupling experimental device and friction load coupling experimental method in marine climate environment

A kind of test equipment and marine climate technology, which is applied in the direction of testing wear resistance, etc., can solve the problems of non-metallic or inorganic material corrosion and wear characteristics evaluation, refractory wear degree evaluation, small movement stroke, etc., to shorten the test period, Equipment maintenance is convenient and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

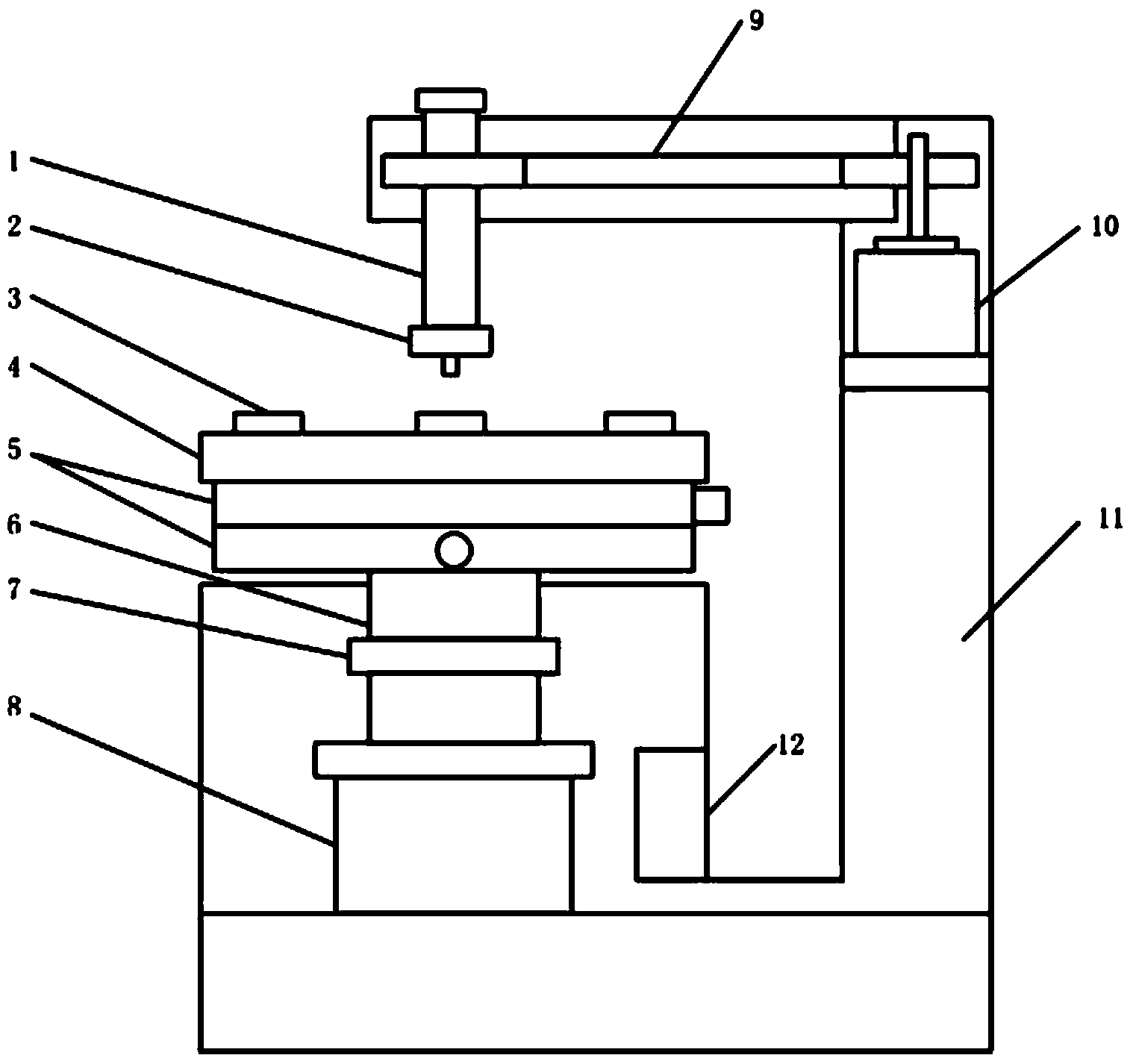

[0064] Alloy steel sample, the size is Φ80×5mm, the surface is polished by ordinary grinder, and the 6 samples are numbered and placed on the figure 1 In the 6 sample fixtures of the middle sample disk, set the load, the rotational speed of the sample pin on the friction pair and the wear time of each sample, and then start loading to wear the No. 1 sample, stop the movement of the friction pair after 30 minutes, and put the upper The sample pin leaves the No. 1 sample, moves to the top of the No. 2 sample, repeats the above process in turn and transfers to other samples. After 10 cycles, each sample can be removed from the sample holder in turn. A digital camera or a stereo microscope is used to observe the change of the surface reflection before and after the corrosion wear, or the weight change of the sample before and after the test is weighed by a precision balance, and then the sample is re-clamped back to the sample holder, and the next round of corrosion wear is carried...

example 2

[0066] Alloy steel sample, the size is Φ80×5mm, the surface is polished by ordinary grinder, the 6 samples are divided into two groups, and they are processed by different heat treatment processes. Number the 6 samples and place them on the figure 1 Among the 6 sample holders in the middle sample tray, samples 1, 2, and 3 are used as one group, and samples 4, 5, and 6 are used as another group. Set the load, the rotational speed of the sample pin on the friction pair and the wear time of each sample, then start loading to wear the No. 1 sample, stop the movement of the friction pair after 30 minutes, and the upper sample pin leaves the No. 1 sample and moves to the No. 2 sample. Right above the number sample, repeat the above process in turn and transfer to other samples. After each sample has gone through 20 cycles, it can be removed from the sample holder in turn, and the corrosion and wear on the surface before and after the corrosion wear can be observed by a digital camer...

example 3

[0068] LC4 aluminum alloy sample, the size is Φ60×5mm, 3 samples as a group (numbered 1, 3, 5), the surface is polished by ordinary grinder, and anodic oxidation treatment is carried out after the 3 samples are polished as For the comparison group (numbered 2, 4, 6), number the 6 samples and place them in the figure 1 In the 6 sample fixtures of the middle sample disk, set the load, the rotational speed of the sample pin on the friction pair and the wear time of each sample, and then start loading to wear the No. 1 sample, stop the movement of the friction pair after 30 minutes, and put the upper The sample pin leaves the No. 1 sample, moves to the top of the No. 2 sample, repeats the above process in turn and transfers to other samples. After 10 cycles, each sample can be removed from the sample holder in turn. Observe the surface changes before and after corrosion wear with a digital camera or a stereo microscope, or weigh the weight change of the sample before and after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com