Variable-frequency spin dryer

A drying machine and frequency conversion technology, which is applied in the direction of drying, drying solid materials, and drying solid materials without heating, etc., can solve the problems of easy wear, high failure rate, and unstable speed of carbon brush machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

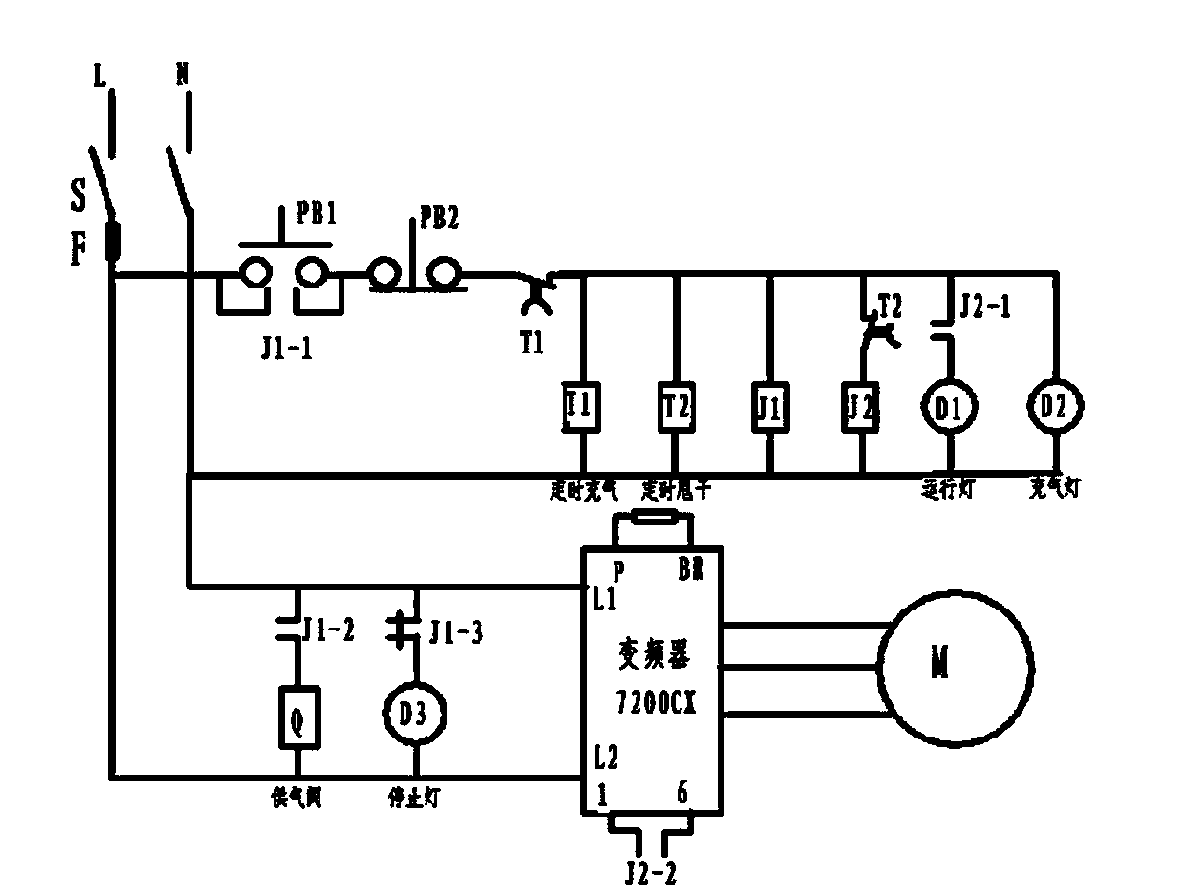

[0015] Below in conjunction with accompanying drawing, content of the present invention will be further described:

[0016] As shown in the figure is the schematic diagram of the structure of the frequency conversion drying machine, including power supply, frequency conversion controller, motor, and rotating drum. The rotating drum is installed on the frame, and the motor drives the rotating drum to rotate through the rotating shaft. AC motors are used, AC motors overcome the defects of DC motors, carbon brush machines are easy to wear, sparking often occurs, and carbon brushes and rotors are burned out. AC frequency conversion speed regulation has the advantages of reliable operation, low failure rate and realization of stepless speed regulation , the frequency conversion controller controls the speed of the motor by adjusting the frequency of the output power supply. The rotating drum is vertical and has a dehydration cavity. A nitrogen connecting pipe is arranged above the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com