Hot-rolled wire rod for manufacturing high-strength container self-tapping screw and production method of hot-rolled wire rod

A hot-rolled wire rod and self-tapping screw technology, which is applied in the direction of manufacturing tools, rolling mill control devices, metal rolling, etc., can solve problems that do not involve the production method of high-strength container self-tapping screws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

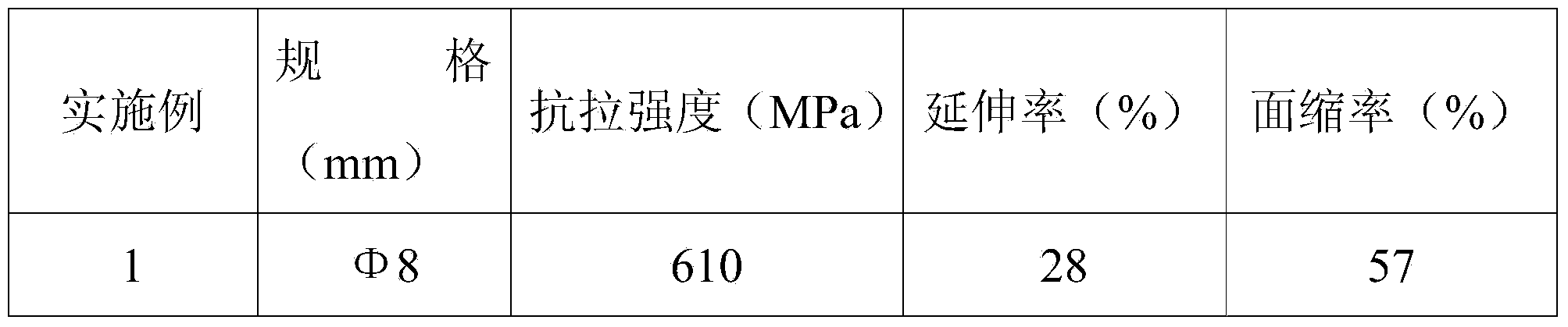

[0078] It is used to manufacture hot-rolled wire rods for high-strength container self-tapping screws. Its chemical composition consists of the following substances by weight percentage (%): C: 0.28%, Mn: 0.86%, Si: 0.06%, P: 0.02%, S : 0.011%, Cr: 0.51%, and the rest are Fe, which are listed in Table 1; the diameter φ8.0mm hot-rolled wire rod produced by the production method of the present invention, the wire rod tensile strength, elongation, and area reduction are listed in Table 2 Among them, 1 / 3 cold heading is qualified, and it has good cleaning performance, which meets the production requirements of high-strength self-tapping screws.

[0079] 1. Smelting

[0080] Using converter or electric furnace for smelting, tapping endpoint control: [C]0.06~0.10%, [P]≤0.015%, [S]≤0.018%. Tapping temperature: 1640-1690°C; implement double slag blocking process: add slag blocking plug before tapping, and add slag blocking rod or slag blocking cone when tapping 4 / 5; alloy and recarbu...

Embodiment 2

[0125] With the method of Example 1, the chemical composition is listed in Table 1, the properties are listed in Table 2, and the rolling process parameters are listed in Tables 3-22 respectively.

Embodiment 3

[0127] With the method of Example 1, the chemical composition is listed in Table 1, the properties are listed in Table 2, and the rolling process parameters are listed in Tables 3-22 respectively.

[0128] Schedule:

[0129] Table 1 Chemical composition (%) table of the embodiment of the present invention

[0130] Example

C

Si

mn

P

S

Cr

Fe

1

0.28

0.06

0.86

0.020

0.011

0.51

margin

2

0.29

0.06

0.88

0.017

0.010

0.54

margin

3

0.27

0.07

0.90

0.019

0.010

0.57

margin

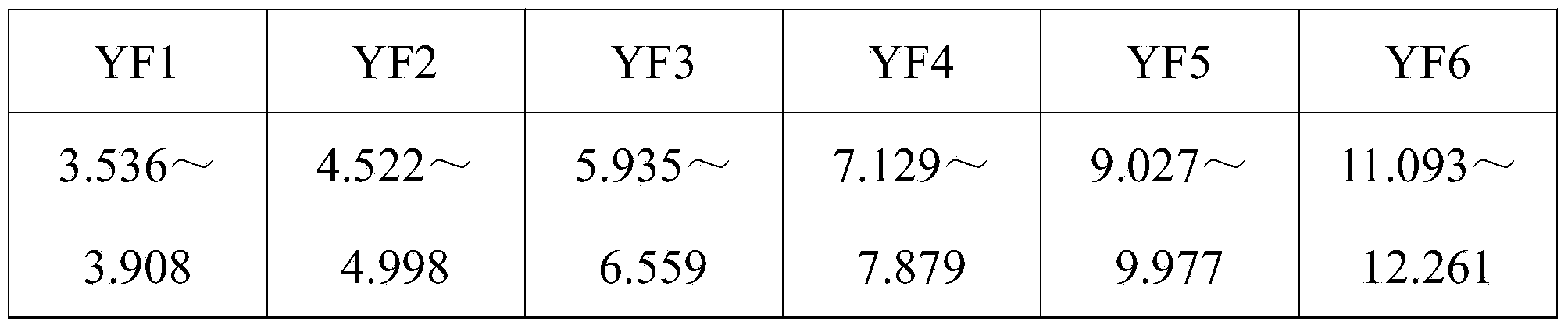

[0131] Table 2 performance table of the embodiment of the present invention

[0132]

[0133]

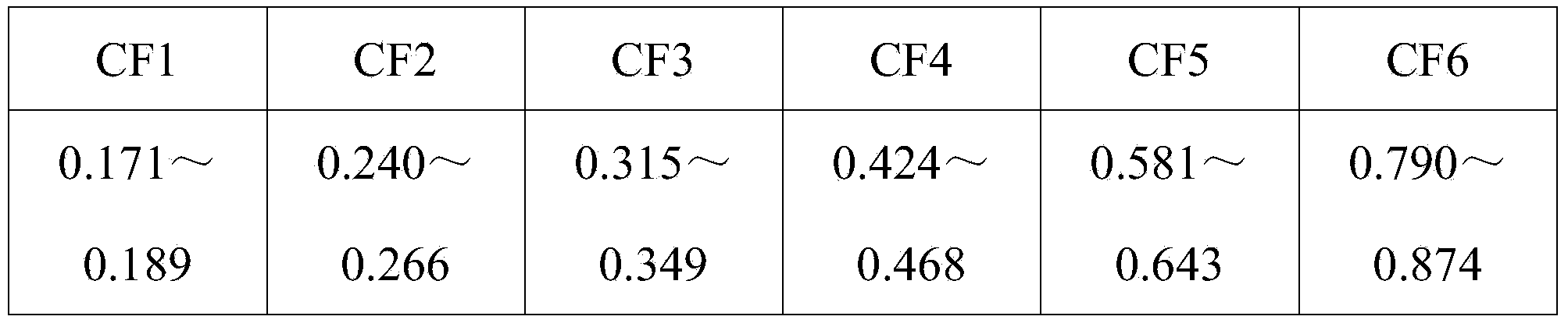

[0134] Table 3 Roll Diameter (mm) of Roughing Mill

[0135] Example

CF1

CF2

CF3

CF4

CF5

CF6

1

548

548

548

467

467

467

2

548

548

548

467

467

467

3

536

536

536...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com