A three-step annealing process for aluminum-free ultra-high carbon steel

A technology of ultra-high carbon steel and annealing process, which is used in manufacturing tools, heat treatment equipment, heat treatment process control, etc., to achieve the effect of low energy consumption and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A three-step annealing process for aluminum-free ultra-high carbon steel, the composition and content expression of the ultra-high carbon steel is Fe-1.58C-1.97Cr-0.26Si-0.73Mn-0.09Mo, the three-step annealing The steps of the process are as follows:

[0020] 1) Austenitizing treatment: heat the material to 840°C at a heating rate of 5°C / min and hold for 2 hours;

[0021] 2) Cooling treatment after austenitization: cooling the austenitized isothermal ultra-high carbon steel from 840°C to 750°C at a cooling rate of 3°C / s;

[0022] 3) Isothermal treatment: The ultra-high carbon steel is isothermally treated at 750°C for 50 minutes, so that the ultra-high carbon steel isothermally obtained a structure composed of pearlite and fine and uniformly distributed granular carbides; after isothermal treatment, the furnace Cool to room temperature.

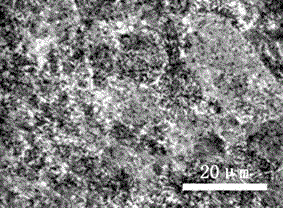

[0023] figure 1 It is the metallographic photograph of the sample obtained in Example 1 of the present invention, and a structure...

Embodiment 2

[0025] A three-step annealing process for aluminum-free ultra-high carbon steel, the composition and content expression of the ultra-high carbon steel is Fe-1.58C-1.97Cr-0.26Si-0.73Mn-0.09Mo, the three-step annealing The steps of the process are as follows:

[0026] 1) Austenitizing treatment: heat the material at a heating rate of 8°C / min to 860°C for 2.5 hours;

[0027] 2) Cooling treatment after austenitization: cooling the austenitized isothermal ultra-high carbon steel from 860°C to 770°C at a cooling rate of 5°C / s;

[0028] 3) Isothermal treatment: The ultra-high carbon steel is isothermally treated at 770°C for 65 minutes, so that the ultra-high carbon steel isothermally obtained a structure composed of pearlite and fine and uniformly distributed granular carbides; after isothermal treatment, the furnace Cool to room temperature.

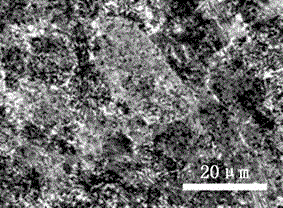

[0029] figure 2 It is the metallographic photograph of the sample obtained in Example 2 of the present invention, and a structure compos...

Embodiment 3

[0031] A three-step annealing process for aluminum-free ultra-high carbon steel, the composition and content expression of the ultra-high carbon steel is Fe-1.58C-1.97Cr-0.26Si-0.73Mn-0.09Mo, the three-step annealing The steps of the process are as follows:

[0032] 1) Austenitizing treatment: heat the material to 880°C at a heating rate of 10°C / min and hold for 3 hours;

[0033] 2) Cooling treatment after austenitization: cooling the austenitized isothermal ultra-high carbon steel from 880°C to 790°C at a cooling rate of 8°C / s;

[0034] 3) Isothermal treatment: Ultra-high carbon steel is isothermally treated at 790°C for 80 minutes, so that ultra-high carbon steel isothermally obtained a structure composed of pearlite and fine and uniformly distributed granular carbides; after isothermal treatment, the furnace Cool to room temperature.

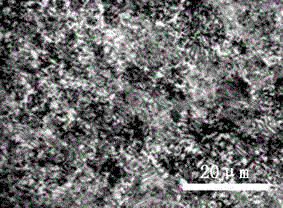

[0035] image 3 It is the metallographic photograph of the sample obtained in Example 3 of the present invention, and a structure compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com