Method for extracting and separating eucommia seed oil and eucommia gum from eucommia samaras

A technology of Eucommia ulmoides seed oil and Eucommia fin fruit is applied in the field of extraction and separation of natural product eucommia gum, which can solve the problems of reducing the elasticity, toughness and tensile strength of eucommia gum, serious structural changes of eucommia gum, large consumption of organic solvents, etc. High-value utilization, comprehensive development and utilization, and low extraction and separation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

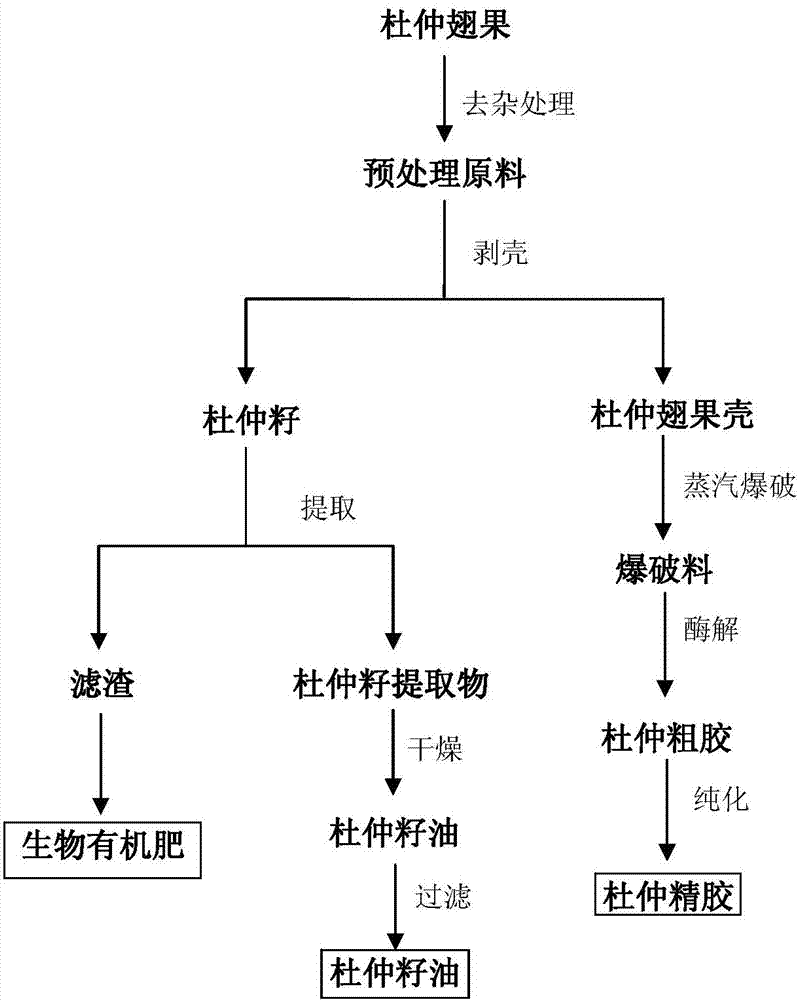

[0033](1) Pre-treatment: After removing impurities from Eucommia ulmoides, the dried eucommia samara is removed with a sheller; the seed kernels are properly mechanically crushed and placed in a dry and cool place for extraction and separation of Eucommia ulmoides fruit seed oil.

[0034] (2) Separation of eucommia seed oil and eucommia gum:

[0035] A. Eucommia gum separation

[0036] a, seed shell steam explosion treatment: the seed shell that step (1) obtains is placed in the water of 30 ℃ and soaks 1h, then the material after soaking is put into steam explosion device and carries out steam explosion, and the pressure of steam explosion is 0.5MPa, control The steam explosion temperature of the steam explosion device is 180°C, the maintenance pressure is 1min, and the material temperature after steam explosion is room temperature;

[0037] b, enzymolysis: the filter residue in step a is added distilled water according to the ratio of material to liquid ratio 1:10, adjusts ...

Embodiment 2

[0044] (1) Pre-treatment: After removing impurities from Eucommia ulmoides, the dried eucommia samara is removed with a sheller; the seed kernels are properly mechanically crushed and placed in a dry and cool place for extraction and separation of Eucommia ulmoides fruit seed oil.

[0045] (2) Separation of eucommia seed oil and eucommia gum:

[0046] A. Eucommia gum separation

[0047] a, seed shell steam explosion treatment: the seed shell that step (1) obtains is placed in the water of 28 ℃ and soaked 4h, then the material after soaking is put into steam explosion device and carries out steam explosion, and the pressure of steam explosion is 0.8MPa, control The steam explosion temperature of the steam explosion device is 170°C, the pressure is maintained for 3 minutes, and the material temperature after steam explosion is room temperature;

[0048] b, enzymolysis: the filter residue in step a is added distilled water according to the ratio of material to liquid ratio 1:25...

Embodiment 3

[0055] (1) Pre-treatment: After removing impurities from Eucommia ulmoides, the dried eucommia samara is removed with a sheller; the seed kernels are properly mechanically crushed and placed in a dry and cool place for extraction and separation of Eucommia ulmoides fruit seed oil.

[0056] (2) Separation of eucommia seed oil and eucommia gum:

[0057] A. Eucommia gum separation

[0058] a, seed shell steam explosion treatment: the seed shell that step (1) obtains is placed in the water of 25 ℃ and soaks 6h, then the material after soaking is put into steam explosion device and carries out steam explosion, and the pressure of steam explosion is 0.9MPa, control The steam explosion temperature of the steam explosion device is 150°C, the pressure is maintained for 5 minutes, and the material temperature after steam explosion is room temperature;

[0059] b, enzymolysis: the filter residue in step a is added distilled water according to the ratio of material to liquid ratio 1:30,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com