Preparation method of macromolecular plasticizer and preparation method of modified polylactic acid

A macromolecular plasticizer and plasticizer technology, applied in the field of polylactic acid, can solve the problems that modified polylactic acid cannot be widely used, the mechanical properties of polylactic acid are poor, and the plasticizer is unstable, so as to improve melt flow properties, improvement of blow molding processability, effect of inhibiting migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The embodiment of the present invention discloses a preparation method of a macromolecular plasticizer, comprising the following steps:

[0036] Mixing the coupling agent and the plasticizer to obtain the first reaction product after reaction;

[0037] The coupling agent is mixed with castor oil, and the second reaction product is obtained after the reaction;

[0038] Mixing the first reaction product with the second reaction product to obtain a macromolecular plasticizer after reaction;

[0039] The plasticizer is citrate triester and its derivatives or macromolecular polyol compound.

[0040] The application firstly provides a preparation method of a macromolecular plasticizer. The plasticizer prepared according to the method provided by the invention has the characteristics of hyperbranched macromolecules. It is used to modify polylactic acid, so that the processing performance of polylactic acid obtained is comparable to that of polylactic acid. The mechanical pro...

Embodiment 1

[0068]A) Put 0.1mol tributyl citrate (TBC) and 0.8mol hexamethylene diisocyanate (HDI) into a dry reaction flask, and stir the reaction at room temperature for a reaction time of 20 hours to ensure TBC The hydroxyl group can be fully replaced by the isocyanate in HDI;

[0069] B) Add 0.2 mol of HDI to 1.25 mol of dry and dewatered castor oil three-necked reaction flask, the system is protected by nitrogen, the reaction temperature is 60°C, and the reaction time is stirred for 10 hours;

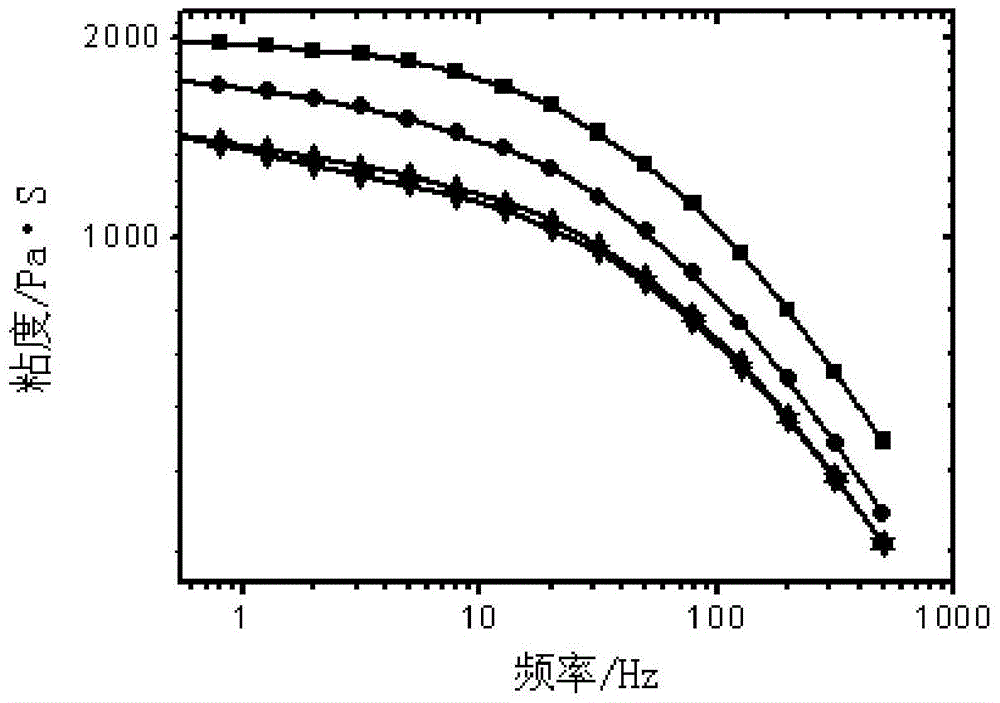

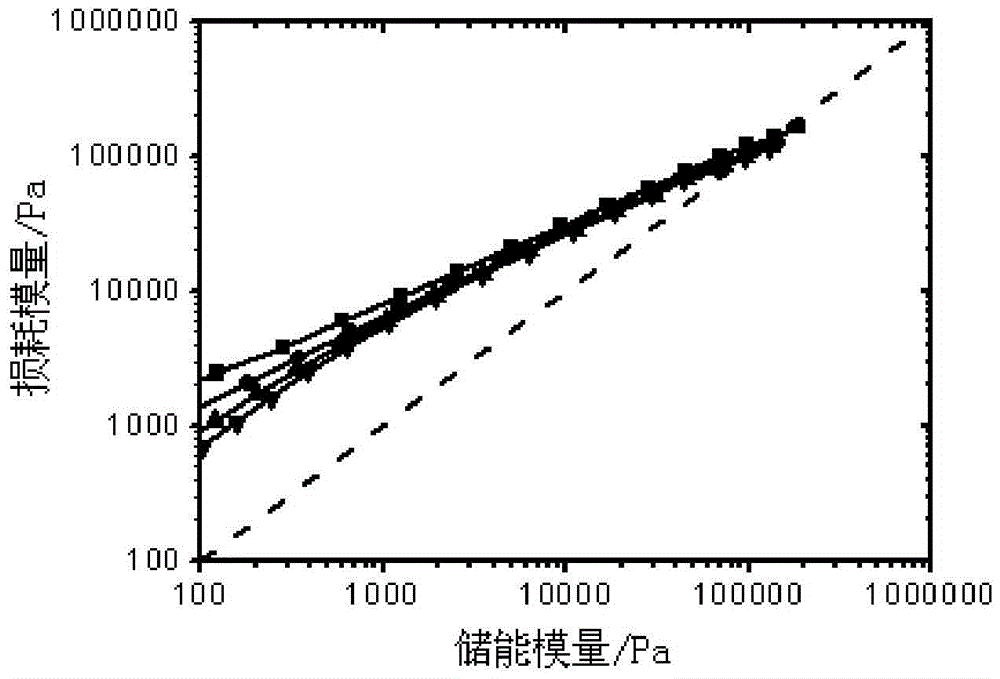

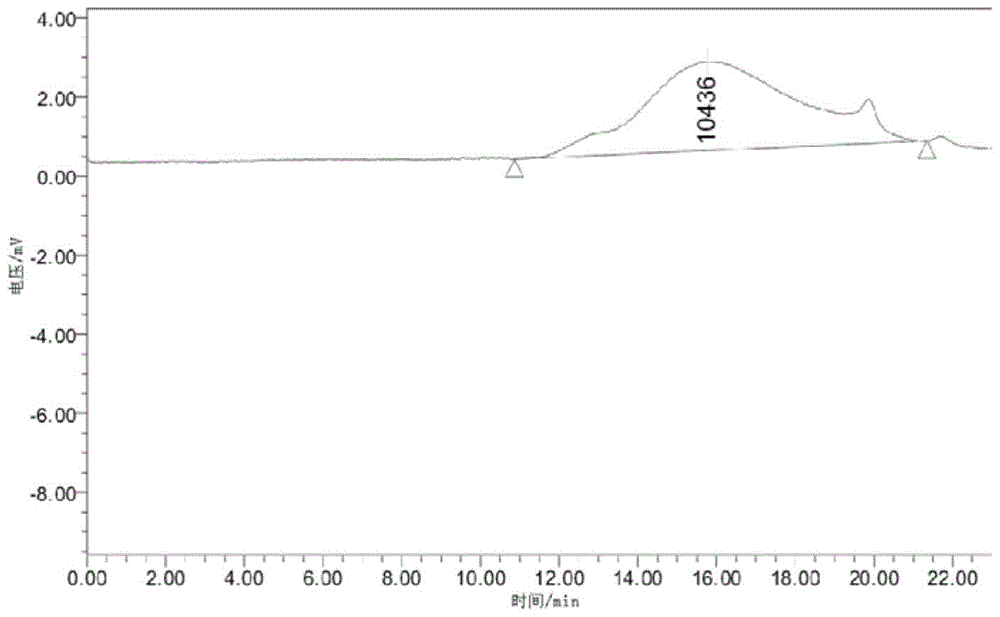

[0070] C) The product of reaction step A) is slowly added dropwise to the product of reaction step B), the reaction temperature is 30 ° C, fully stirred, the reaction time is equivalent to the dropping time, and a hyperbranched macromolecular plasticizer prepolymer is obtained; Gel permeation chromatography (GPC) detects the plasticizer prepared in this embodiment, such as image 3 as shown, image 3 The GPC curve chart of the macromolecular plasticizer prepared for this example, the test re...

Embodiment 2

[0076] A) Put 0.2mol acetyl tributyl citrate (ATBC) and 1mol 4,4'-methylene diisocyanate phenyl (MDI) into a dry reaction flask, and stir the reaction at room temperature, The reaction time is 20 hours to ensure that the hydroxyl group of ATBC can be fully replaced by the isocyanate group in MDI;

[0077] B) 0.2 mol of MDI was added to 2.0 mol of dry and dehydrated castor oil three-neck reaction flask, the system was protected by nitrogen, the reaction temperature was 60°C, and the reaction time was stirred for 15 hours;

[0078] C) adding the product of the reaction step A) slowly to the product of the reaction step B), the reaction temperature is 30° C., fully stirred, and the reaction time is equivalent to the dropping time to obtain a hyperbranched macromolecular plasticizer prepolymer;

[0079] D) fully mixing the hyperbranched macromolecular plasticizer and polylactic acid, adding to a twin-screw extruder for melt extrusion and granulation to obtain a polylactic acid mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com