Hydroxyl acrylic resin and preparation method thereof

A hydroxy acrylic resin technology, applied in the field of hydroxy acrylic resin and its preparation, can solve the problems of low viscosity, fast surface drying speed and high hardness of hydroxy acrylic resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

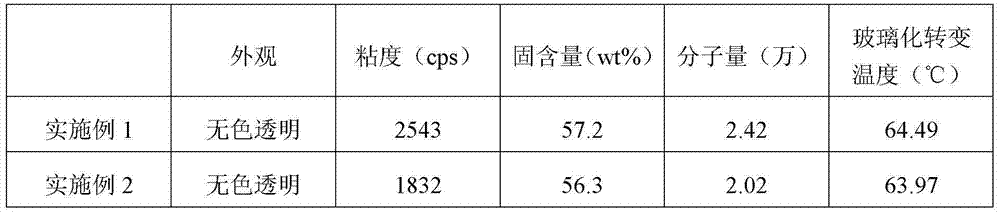

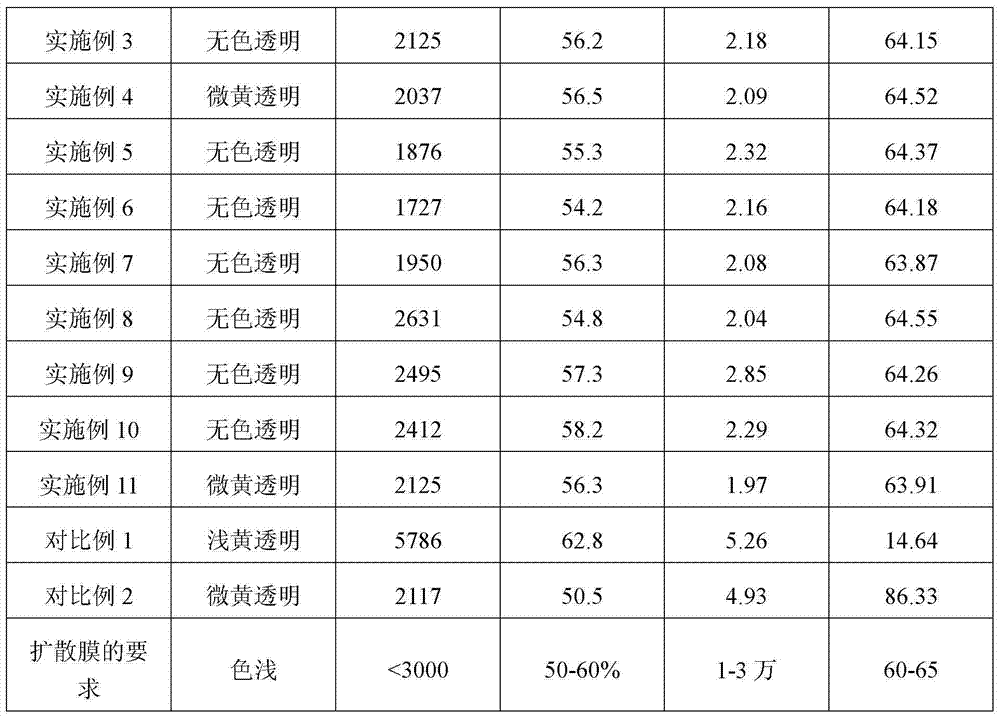

Examples

preparation example Construction

[0036] In another typical embodiment of the present invention, a method for preparing the above-mentioned hydroxy acrylic resin is also provided. The preparation method includes: step S1, mixing hard monomers, soft monomers, hydroxyl monomers, carboxyl monomers, The initiator and the chain transfer agent are reacted in an organic solvent at 100-120° C. to form a reaction system; step S2, cooling the reaction system below 100° C. and then filtering to obtain a hydroxyacrylic resin.

[0037] The raw materials with the above ratio are used to react under the above conditions, and the various parameters and properties of the obtained hydroxyacrylic resin can meet the requirements of the diffusion film; the above preparation method is simple in process and can be widely popularized and applied on the basis of the existing technology.

[0038] Each step of the above-mentioned preparation method can be implemented with reference to the prior art. Preferably, the above-mentioned step S...

Embodiment 1

[0043] First, add 50 parts of toluene and 25 parts of butyl acetate to the reaction kettle in parts by weight, raise the temperature to about 115°C, and reflux the solvent; then, maintain the temperature of the above solvent at about 115°C, and dissolve 50 parts of methyl acetate within 3 hours A mixture of methyl acrylate, 23 parts of styrene, 17 parts of butyl acrylate, 16 parts of hydroxyethyl methacrylate, 1 part of acrylic acid, 2.5 parts of tert-butyl peroxybenzoate, and 2 parts of n-dodecyl mercaptan Add it dropwise to the reaction kettle to form the first system; after making the first system keep warm for 2 hours, add a mixture of 0.5 parts of tert-butyl peroxybenzoate, 10 parts of toluene and 5 parts of butyl acetate dropwise to the In the reaction kettle, and continue to keep warm for 2 hours to obtain a reaction system, the temperature of the reaction system is lowered to below 70°C, discharged and filtered to obtain the hydroxyacrylic resin of Example 1.

Embodiment 2

[0045] Add 70 parts of butyl acetate to the reaction kettle in parts by weight, raise the temperature to about 128°C, and reflux the solvent; then, maintain the temperature of the above solvent at about 128°C, add 46 parts of methyl methacrylate, A mixture of styrene, 12 parts of butyl acrylate, 14 parts of hydroxyethyl methacrylate, 0.8 parts of acrylic acid, 2.4 parts of dicumyl peroxide, and 2 parts of n-dodecyl mercaptan was added dropwise to the reactor at a constant rate The first system is formed; after the first system is incubated and reacted for 2 hours, a mixture of 0.4 parts of tert-butyl peroxybenzoate and 10 parts of butyl acetate is added dropwise to the reactor within 1 hour, and the reaction is continued for 2 hours to obtain For the reaction body, the temperature of the reaction system was lowered to below 70° C., and the material was discharged and filtered to obtain the hydroxyacrylic resin of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com