Method for refining acetylene

An acetylene, first-line technology, applied in the field of removing high-grade alkynes, can solve the problems of solvent boiling point and flash point, low evaporation loss and entrainment loss, inability to realize industrialization, etc., and achieves easy operation and control of operating temperature and pressure, and high flash point. and the effect of mild boiling point, absorption and regeneration conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

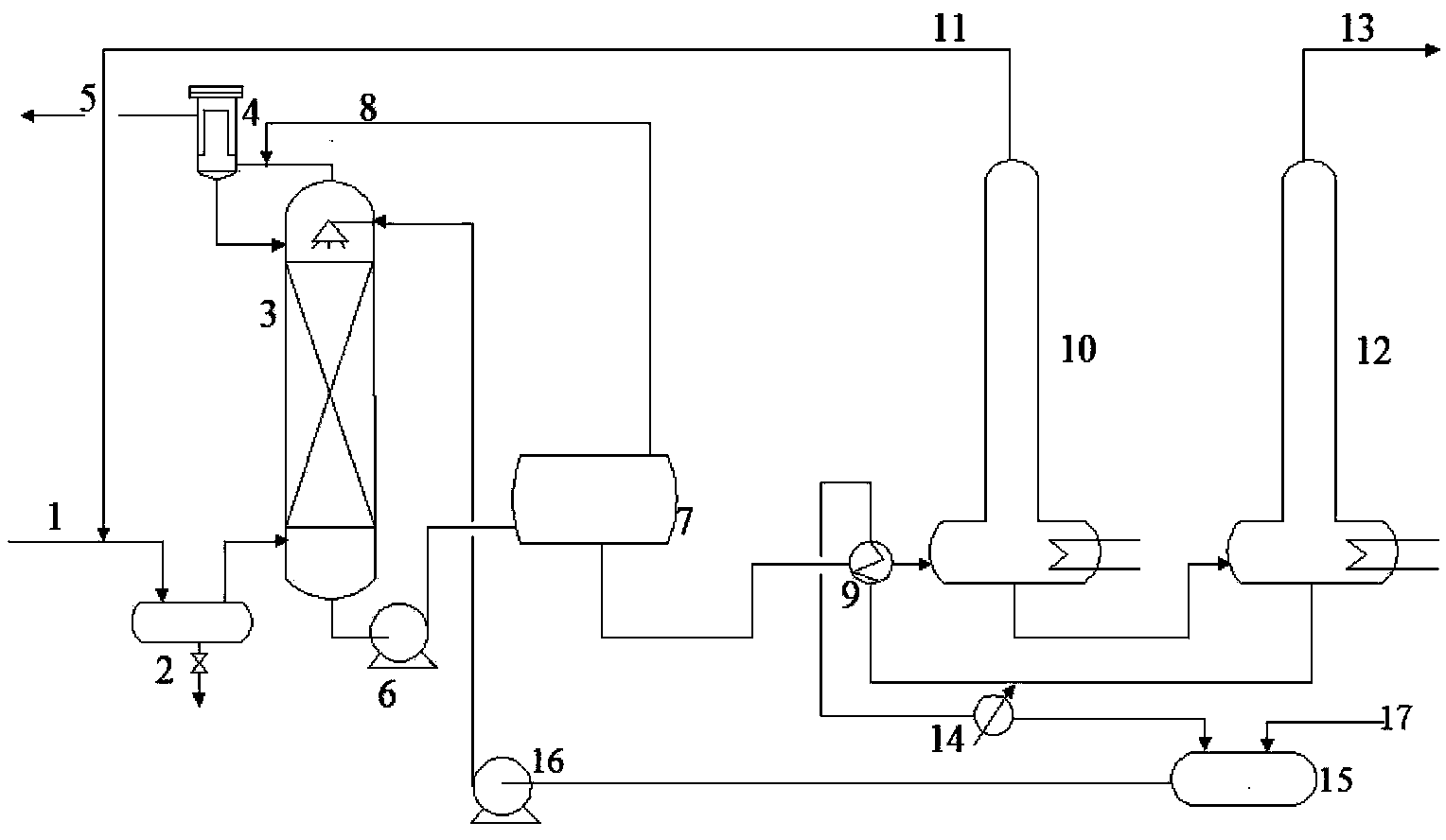

[0033] Raw material air velocity 16h -1 , the pressure is 0MPa, the composition is 98.9603% of acetylene, 0.3105% of propadiene, 0.4515% of propyne, and 0.2726% of permanent gas; the absorption solvent is liquid paraffin with a boiling range of 185-250 °C, and the space velocity is 2.40 h -1 ; The absorption temperature of tower (3) is 15°C; the temperature of tower (7) is 25°C, the residence time is 3min; the temperature of tower (10) is 60°C, 5min; the temperature of tower (12) is 85°C, the residence time is 10min, the vacuum degree After the experimental device runs stably, analyzing the gas composition at the inlet and outlet of each tower shows that the product gas purity is 99.64%, the propadiene removal rate is 100%, the propyne removal rate is 99.96%, and the acetylene yield is 99.70%.

Embodiment 2

[0035] Raw material air velocity 20h -1, the pressure is 0.03MPa, the raw material composition is 98.8472% of acetylene, 0.3092% of propadiene, 0.4156% of propyne, and 0.4276% of permanent gas; the absorption solvent is reduced-line distillate oil with a boiling range of 320-400 ℃, and the space velocity is 2.25 h -1 ; The absorption temperature of tower 3 is 25°C; the temperature of tower 7 is 35°C and the residence time is 7min; the temperature of tower 10 is 80°C and the residence time is 10min; the temperature of tower 12 is 100°C and the residence time is 30min; After stable operation, analysis of the gas composition at the inlet and outlet of each tower shows that the purity of the product gas is 99.52%, the removal rate of propadiene is 99.8%, the removal rate of propyne is 99.94%, and the yield of acetylene is 99.98%.

Embodiment 3

[0037] Raw material air velocity 18h -1 , the pressure is 0.08MPa, the raw material composition is 98.7347% of acetylene, 0.3376% of propadiene, 0.4289% of propyne, and 0.4988% of permanent gas; the absorption solvent is ordinary second-line distillate oil with a boiling range of 200-260 °C, and the space velocity is 2.15 h -1 The absorption temperature of tower 3 is 18°C; the temperature of tower 7 is 28°C, the residence time is 5min, the temperature of tower 10 is 65°C, the residence time is 8min; the temperature of tower 12 is 88°C, the residence time is 15Min, and the vacuum degree is 35 KPa; After stable operation, analysis of the gas composition at the inlet and outlet of each tower shows that the purity of the product gas is 99.64%, the removal rate of propadiene is 100%, the removal rate of propyne is 100%, and the yield of acetylene is 99.92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com