Industrial wastewater treatment method

A treatment method and technology for industrial wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as difficult discharge, difficult treatment, environmental pollution, etc., and achieve water quality Strong adaptability, accelerated degradation rate, and increased cycle times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

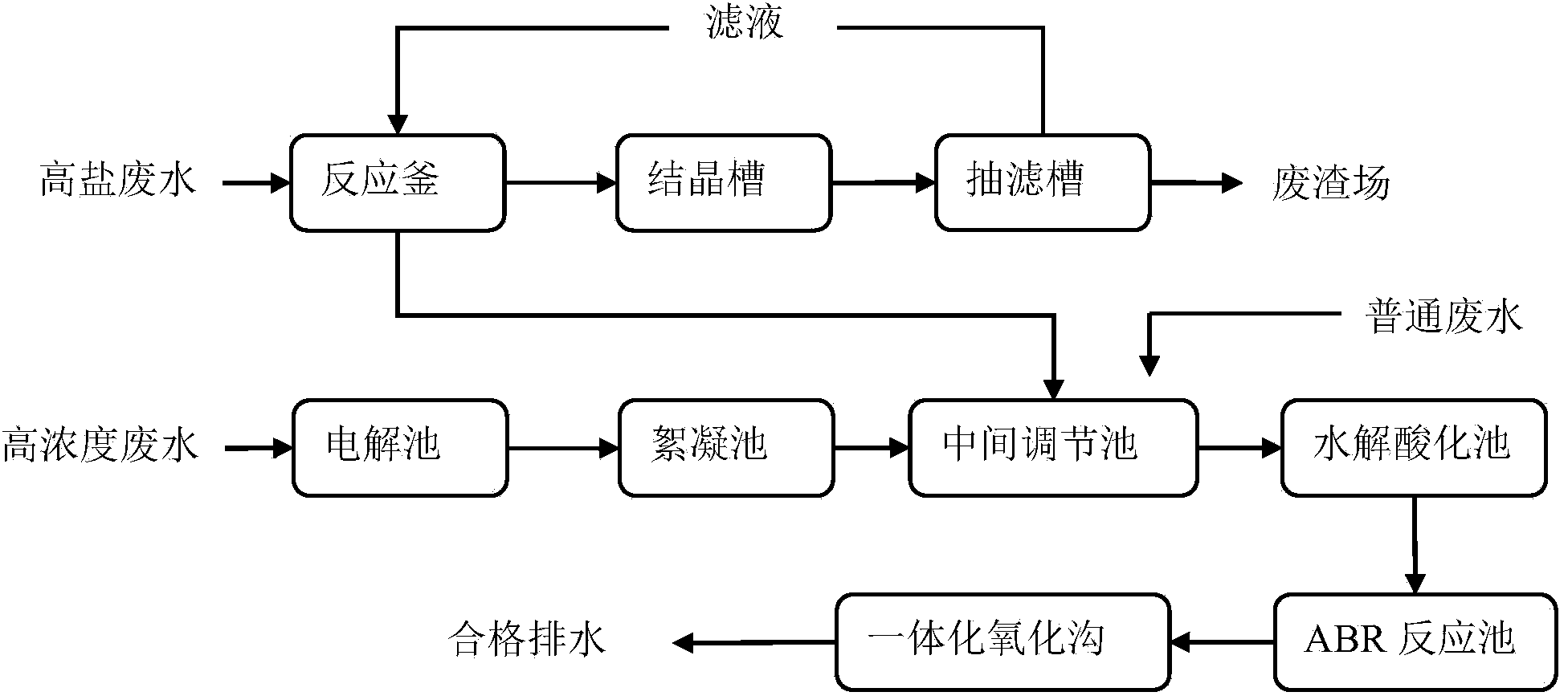

Embodiment 1

[0020] High-salt wastewater, the salt content is as high as 20%, and the CODcr is 2500mg / L. This part of the wastewater is passed into the reactor, the vacuum pump depressurizes, the pressure is 0.04-0.06MPa, and the steam is heated at 85 degrees for 4 hours, and the volatile organic compounds are discharged from the top of the reactor. The escape is collected into the intermediate adjustment tank, the residual liquid is discharged into the crystallization tank to cool for 1 hour, the solid salts are filtered off by suction and sent directly to landfill, and the filtrate is returned to the reactor. High-concentration wastewater, high concentration of organic matter, CODcr as high as 25000mg / L, this part of wastewater is added to the electrolytic cell, and iron and graphite positive and negative are used for micro-electrolysis, and the ferrous ions produced at the same time have a catalytic effect, and the input amount of oxidant hydrogen peroxide is 10mmol / L, the reaction time...

Embodiment 2

[0022] High-salt wastewater, the salt content is as high as 20%, and the CODcr is 2500mg / L. This part of the wastewater is passed into the reactor, the vacuum pump depressurizes, the pressure is 0.04-0.06MPa, and the steam is heated at 85 degrees for 4 hours, and the volatile organic compounds are discharged from the top of the reactor. The escape is collected into the intermediate adjustment tank, the residual liquid is discharged into the crystallization tank to cool for 1 hour, the solid salts are filtered off by suction and sent directly to landfill, and the filtrate is returned to the reactor. High-concentration wastewater, high concentration of organic matter, CODcr as high as 25000mg / L, this part of wastewater is added to the electrolytic cell, and iron and graphite positive and negative are used for micro-electrolysis, and the ferrous ions produced at the same time have a catalytic effect, and the input amount of oxidant hydrogen peroxide is 10mmol / L, the reaction time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com