Fixed base ensuring positioning precision and use method thereof

A technology of positioning accuracy and fixed seat, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of prone to overturning and tipping of the fixed seat, and achieve the effects of simple structure, interference avoidance, and stable fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

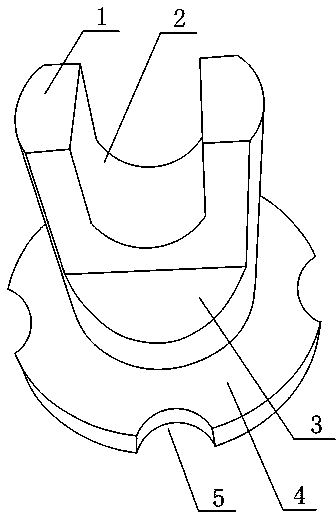

[0016] like figure 1 As shown, the fixed seat to ensure the positioning accuracy includes a base 4, and the base 4 is provided with several positioning holes 5, and the positioning holes 5 are through holes formed on the upper end surface of the base 4, and each through The holes are all in communication with the wall of the base 4 ; the preferred number of positioning holes 5 is four, and they are evenly distributed on the base 4 .

[0017] The positioning hole 5 is used as the installation channel of the grounding bolt, and the nut of the grounding bolt is in contact with the upper surface of the base 4. The size of the nut of the grounding bolt is larger than the size of the positioning hole 5, so that the nut can be clamped on the base 4. During loading and unloading, the grounding bolt can be easily taken out, avoiding the phenomenon of interference, and the positioning hole 5 is provided to increase the stability during work, so that the stability of the fixing seat is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com