CNC (Computer Numerical Control) six-axis linked sanitary casting machining device

A six-axis linkage and casting technology, which is applied in the direction of grinding workpiece brackets, metal processing equipment, manufacturing tools, etc., can solve problems such as complex shapes, products that cannot be adapted to surface processing, and low production efficiency, and achieve flatness and edge corrugation Line rules, reducing appearance defects and scrapping, improving production capacity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment, further illustrate the present invention.

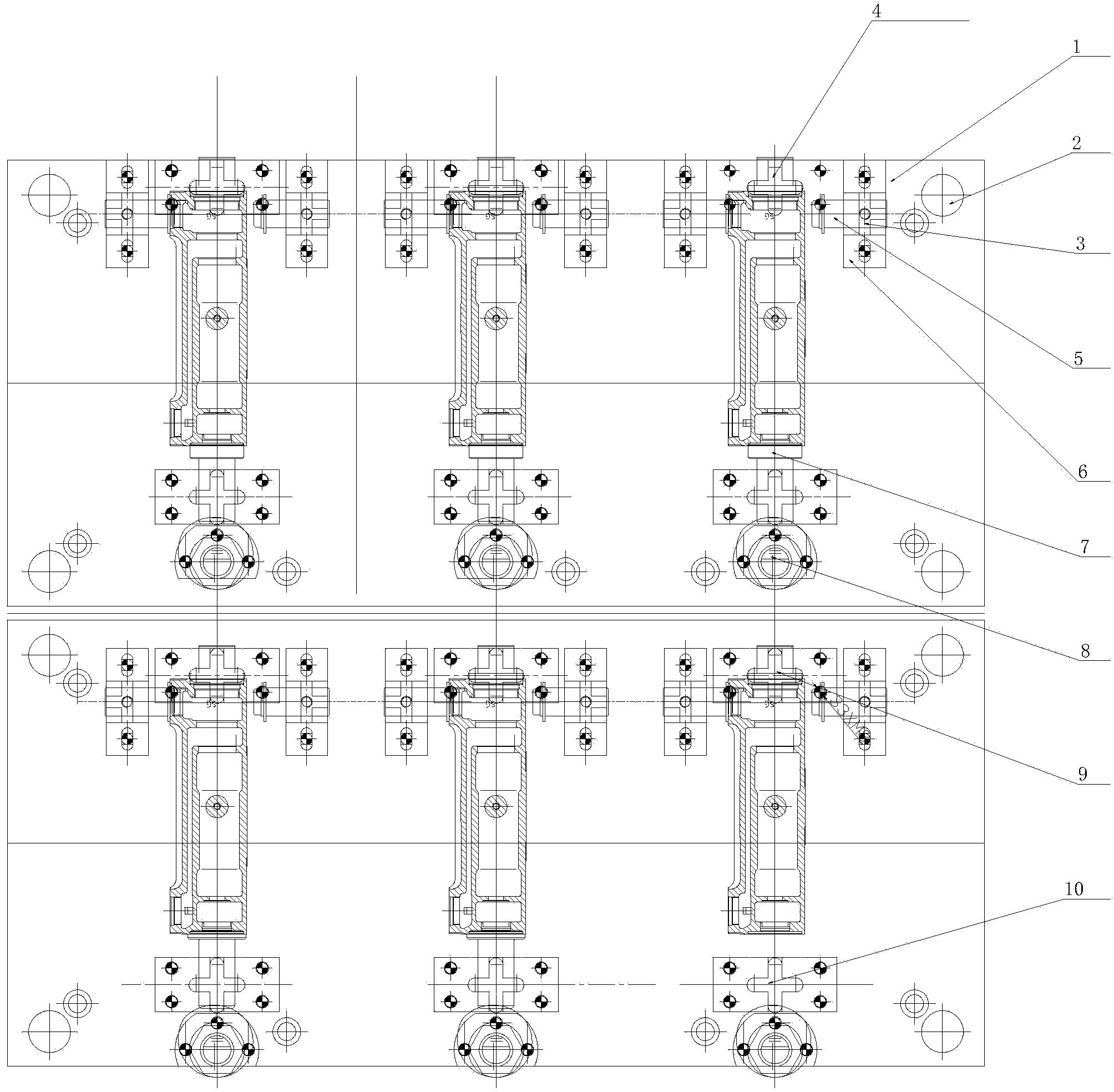

[0024] A CNC six-axis linkage machining device for bathroom castings, characterized in that it includes the following components, a large body plate (1), a clamp, and a body positioning pin (2);

[0025] The number of the clamps is 6, and they are installed on the main body plate (1), and the number of the body positioning pins (2) is four, which are located at the four corners of the main body plate (1), and are used for the main body plate (1) The positioning makes the repeat position accuracy of the fixture reach 0.01mm;

[0026] The fixture includes a first cross positioning key (3), a left valve chamber positioning device (4), a water entry positioning device (5), a water entry positioning sleeve (6), a right valve chamber positioning device (7), an eccentric cam mechanism (8 ),

[0027] The left valve chamber positioning device (4) is located at the upper end of the clamp,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com