Preparation method of lactose-free fermented dairy product

A technology of fermented milk products and fermented milk, which is applied in the direction of dairy products, milk preparations, applications, etc., can solve problems such as inability to drink, and achieve the effect of avoiding difficult control and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

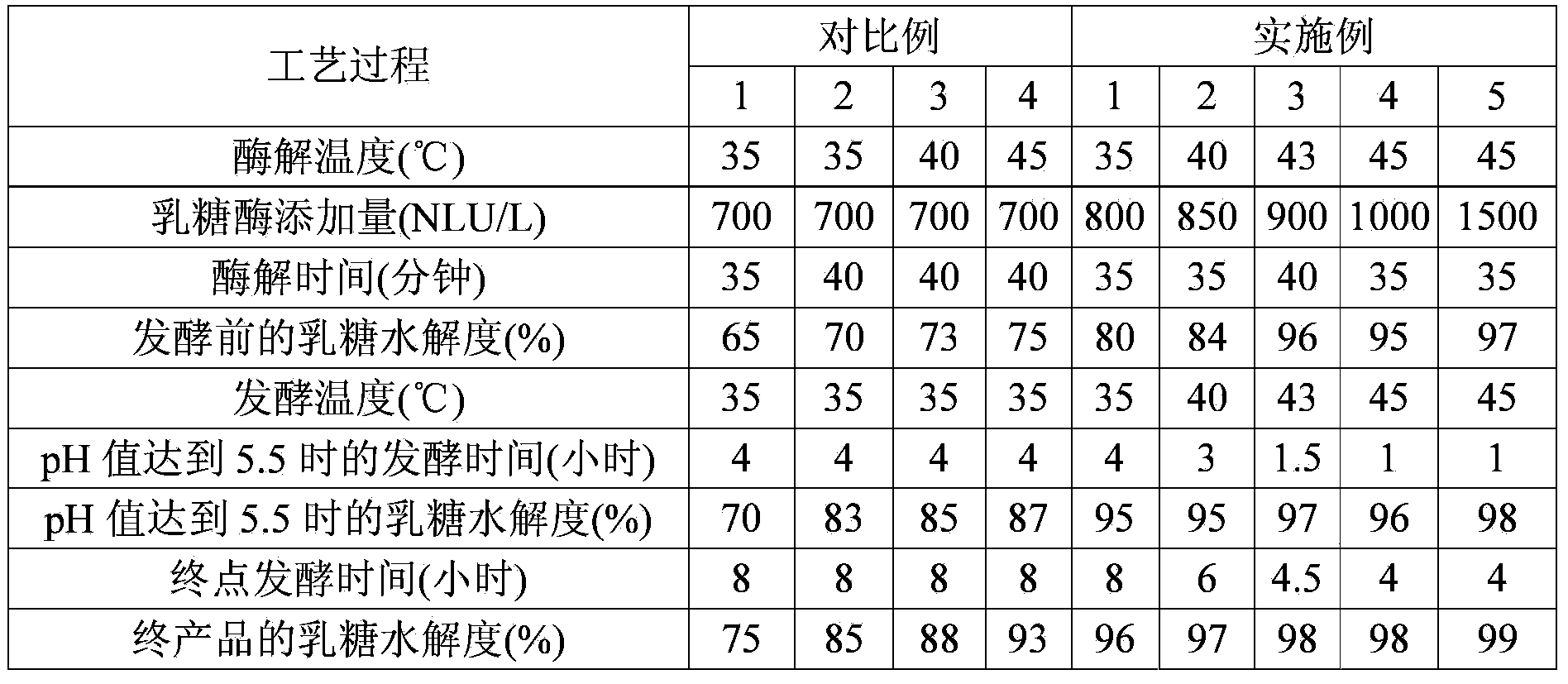

Embodiment 1

[0029] This embodiment provides a method for preparing a lactose-free fermented milk product, which comprises the following steps:

[0030] (1) Mixing: Mix milk, white granulated sugar, concentrated whey protein powder, concentrated milk protein powder, modified starch, agar and pectin at 50-55°C, and circulate for 30-35 minutes. Calculated, the addition amount of each raw material is: white granulated sugar 7.5%, the total amount of concentrated whey protein powder and concentrated milk protein powder 2% (ratio 1:1), modified starch 4%, agar 0.3%, pectin 0.1% and milk balance;

[0031] (2) Homogenization: Homogenize the mixed material liquid, the homogenization temperature is 60-65°C, the pressure is 25Mpa, and the primary pressure accounts for 50% to 60% of the total pressure;

[0032] (3) Sterilization: Sterilize the homogenized feed liquid at a temperature of 95°C for 5 minutes;

[0033] (4) Enzymolysis and fermentation: cool down the sterilized feed liquid to 35°C, then...

Embodiment 2

[0038]This example provides a method for preparing a lactose-free fermented milk product, which is basically the same as that of Example 1, except for the steps of enzymatic hydrolysis and fermentation. The steps of enzymolysis and fermentation in the preparation method of the present embodiment are:

[0039] Lower the temperature of the sterilized feed liquid to 40°C, and then add lactase to it for enzymolysis. The amount of lactase added is 850 NLU / L based on the volume of milk;

[0040] After 35 minutes of enzymatic hydrolysis, when the hydrolysis degree of lactose reaches 84%, add Lactobacillus bulgaricus and Streptococcus thermophilus in total 120DCU (ratio 1:2) to ferment at 40°C. After 3 hours, when the pH value of the feed solution reaches 5.5, Lactase begins to inactivate, and the degree of hydrolysis of lactose reaches 95% at this time;

[0041] After continuing to ferment for 3 hours, when the pH value of the feed liquid reaches 4.3-4.5, the fermentation ends, and ...

Embodiment 3

[0043] This example provides a method for preparing a lactose-free fermented milk product, which is basically the same as that of Example 1, except for the steps of enzymatic hydrolysis and fermentation. The steps of enzymolysis and fermentation in the preparation method of the present embodiment are:

[0044] Lower the temperature of the sterilized feed liquid to 43°C, and then add lactase to it for enzymolysis. The amount of lactase added is 900 NLU / L based on the volume of milk;

[0045] After 40 minutes of enzymolysis, when the hydrolysis degree of lactose reaches 96%, add Lactobacillus bulgaricus and Streptococcus thermophilus in total 150 DCU (ratio 1:1) at 43°C for fermentation, and after 1.5 hours, when the pH value of the feed solution reaches 5.5, Lactase begins to inactivate, and the degree of hydrolysis of lactose reaches 97% at this time;

[0046] After continuing to ferment for 3 hours, when the pH value of the feed liquid reaches 4.3-4.5, the fermentation ends,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com