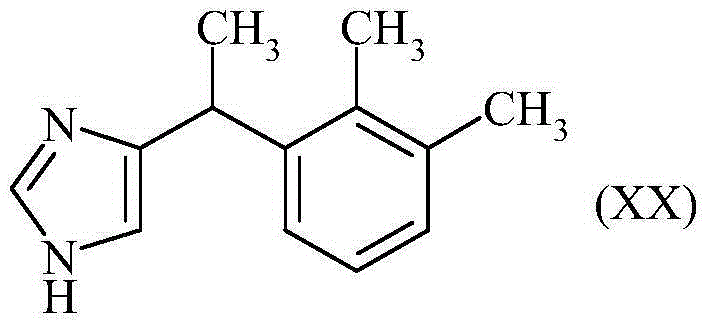

Method for preparing 2-(2,3-dimethylphenyl)-1-propanal with chloroacetone

A technology of chloroacetone and propylmagnesium bromide, applied in the field of preparing 2--1-propanal, which can solve the problems of expensive, long time, and difficult to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0231] Example 1: 2-(2,3-Dimethylphenyl)methyloxirane, compound of formula (XXII), metal substitution with butyllithium in THF

[0232] To a solution of 1-bromo-2,3-dimethylbenzene (0.27ml, 2.0mmol) dissolved in THF (4.0ml) was added n-butyllithium (2.0ml of 1.6M hexane solution, 3.2 mmol). The mixture was stirred at -78°C for 30 minutes, then a solution of chloroacetone (0.24ml, 3.0mmol) dissolved in toluene (0.42ml) was added dropwise over 20 minutes. The mixture was stirred at -78°C for 1 hour, then allowed to warm to room temperature. Analysis of a sample after 3 hours at room temperature showed the title epoxide to be the major reaction product. After stirring at room temperature for 3 days, the mixture was poured into water (20ml) and the product was extracted with ethyl acetate (1 x 10ml, 2 x 5ml). The combined extracts were washed with MgSO 4 Drying and concentration under reduced pressure afforded the title epoxide as an oil in quantitative yield.

[0233] 1 HNM...

Embodiment 2

[0235] Example 2: 2-(2,3-Dimethylphenyl)methyloxirane, compound of formula (XXII), metallized with magnesium in THF

[0236] To a suspension of magnesium (89 mg, 3.66 mmol) in THF (4.0 ml) was added NaH (81 mg, 60% in oil, 2.0 mmol) and after stirring at room temperature for 10 minutes, 1-bromo-2,3 - Dimethylbenzene (0.40ml, 2.96mmol). An exothermic reaction ensued and the resulting mixture was stirred at room temperature for 1 hour. The mixture was then cooled to -20°C and a solution of chloroacetone (0.26ml, 3.3mmol) dissolved in toluene (0.63ml) was added dropwise over 10 minutes. The mixture was then stirred at room temperature for 2 hours. The samples were worked up by mixing with water, extracting with ethyl acetate, evaporating the ethyl acetate with a stream of nitrogen. use 1 HNMR analysis of the residue showed it to be a mixture of xylenes and the title oxirane compound.

Embodiment 3

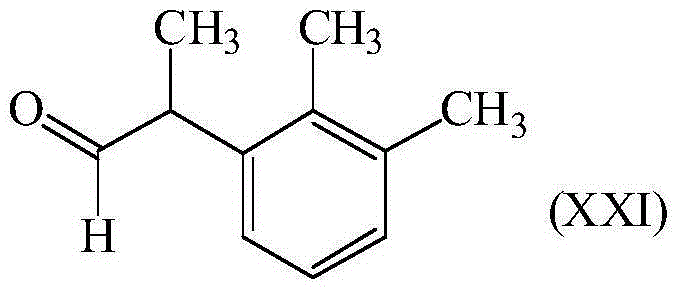

[0237] Example 3: 2-(2,3-Dimethylphenyl)propanal, compound of formula (XXI)

[0238] The 2-(2,3-dimethylphenyl)methyloxirane prepared according to Example 1, the compound of formula (XXII) (158mg, 0.97mmol) was dissolved in toluene (1.57mL), and at room temperature Join BF under 3 OEt 2 (0.006ml, 0.05mmol). After 2 hours at room temperature the sample was mixed with solid NaHCO 3 Mix, filter, concentrate under reduced pressure, use 1 The residue was analyzed by HNMR. The crude product consisted essentially of pure 2-(2,3-dimethylphenyl)propanal.

[0239] 1 HNMR: 1.40(d, J=7.1Hz, 3H), 2.25(s, 3H), 2.32(s, 3H), 3.89(qd, J=7.1, 1.0Hz, 1H), 6.89 to 6.92(m, 1H) , 7.12 (m, 2H), 9.67 (d, J=1.0Hz, 1H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com