Double-medium low-temperature plasma generator

A low-temperature plasma and dual-media technology, which is applied in the direction of plasma and electrical components, can solve the problems of large volume and increased vehicle weight, and achieve the effects of uniform distribution, reduced deposition, and avoided corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

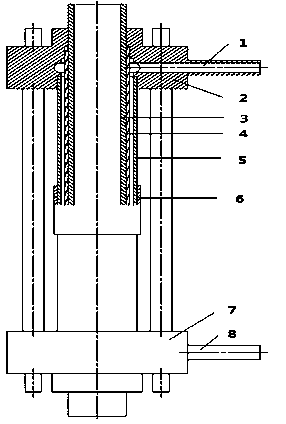

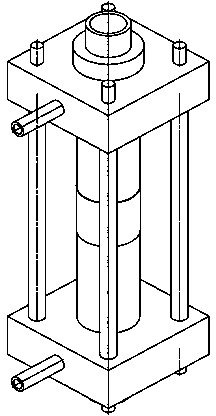

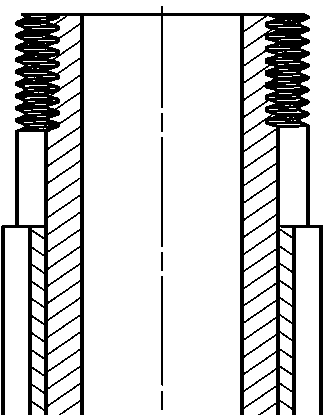

[0024] A double dielectric barrier discharge low-temperature plasma generator of the present invention, its axial section structure and overall three-dimensional structure are respectively as follows figure 1 and figure 2 Shown: Including intake pipe 1, cast iron plug Ⅰ 2, low-voltage electrode 3, quartz glass inner tube 4, quartz glass outer tube 5, high-voltage electrode 6, cast iron plug Ⅱ 7, exhaust pipe 8. The local structure of the generator is as image 3 As shown, the internal local structure of the cast iron plug I2 is as follows Figure 4 shown.

[0025] The device of the present invention adopts a coaxial structure, and the cast iron plug I2 and the cast iron plug II7 are symmetrically nested at both ends of the quartz glass inner tube 4 and the quartz glass outer tube 5, and the quartz glass inner tube 4 and the quar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com