Jack contact and contact units

A socket contact piece and monomer technology, which is applied in the field of socket contact pieces and their contact monomers, can solve problems such as waste of socket contact pieces, achieve the effect of solving waste and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

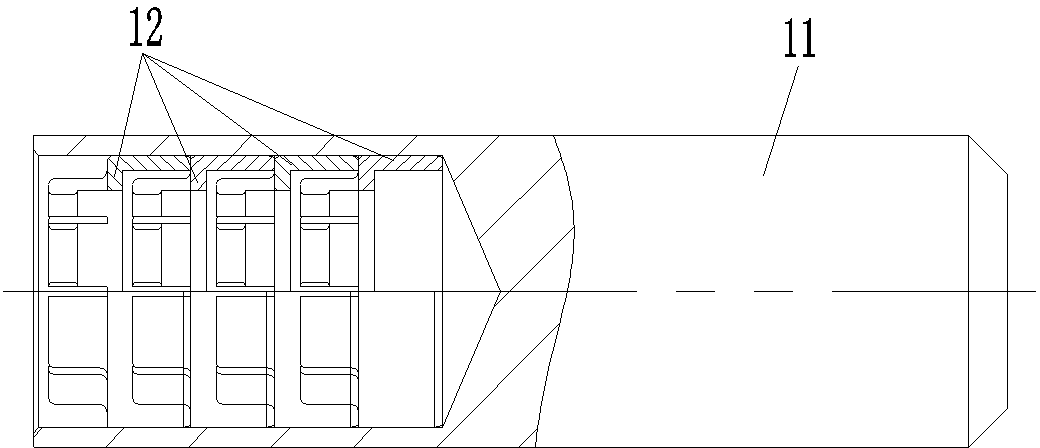

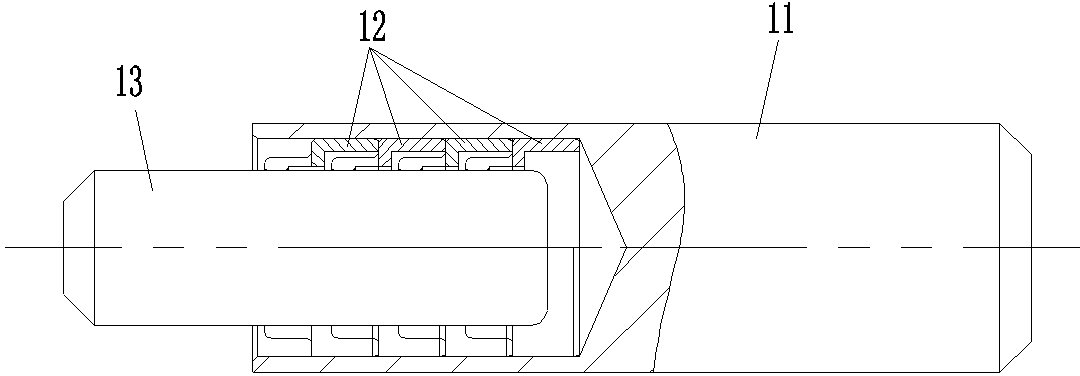

[0021] Examples of socket contacts, such as Figure 1-4 As shown, the conductive sleeve 11 is included, and the front part of the conductive sleeve 11 has an insertion hole for the adapter pin to be inserted into. In this embodiment, the insertion hole is a blind hole.

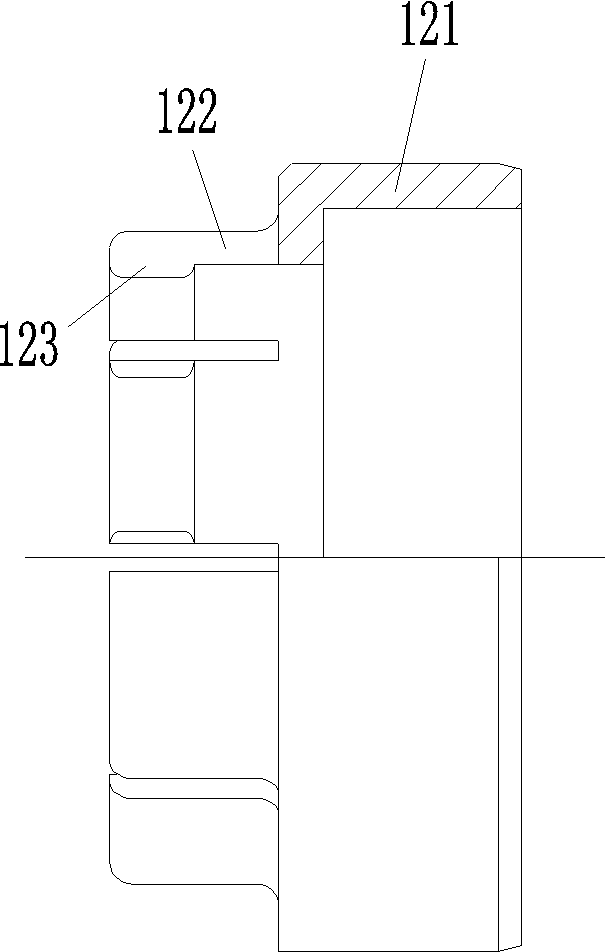

[0022] A contact unit 12 is assembled in the insertion hole. In this embodiment, there are four contact units 12, and each contact unit 12 includes a fixing sleeve 121 coaxially arranged with the insertion hole and a fixing sleeve arranged on the fixing sleeve. The cantilever spring claw 122 at the front end, the interference fit between the fixed sleeve 121 and the conductive sleeve 11, there is an avoidance gap between the back of the spring claw 122 and the hole wall of the insertion hole. In this embodiment, the contact A stepped surface facing forward is formed between the claw back of the monomer 12 and the outer peripheral surface of the fixed sleeve, and the avoidance gap is formed by the height differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com