Heat sink

A heat sink and heat sink technology, applied in heat exchange equipment, lighting and heating equipment, cooling/heating devices of lighting devices, etc., can solve the problem of high difficulty in controlling the thickness precision of heat sinks, different production molds for heat sinks, and LED heat dissipation Eliminate problems such as device scrapping, achieve the effects of reducing weight and consumables, high assembly efficiency, and reducing the difficulty of production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

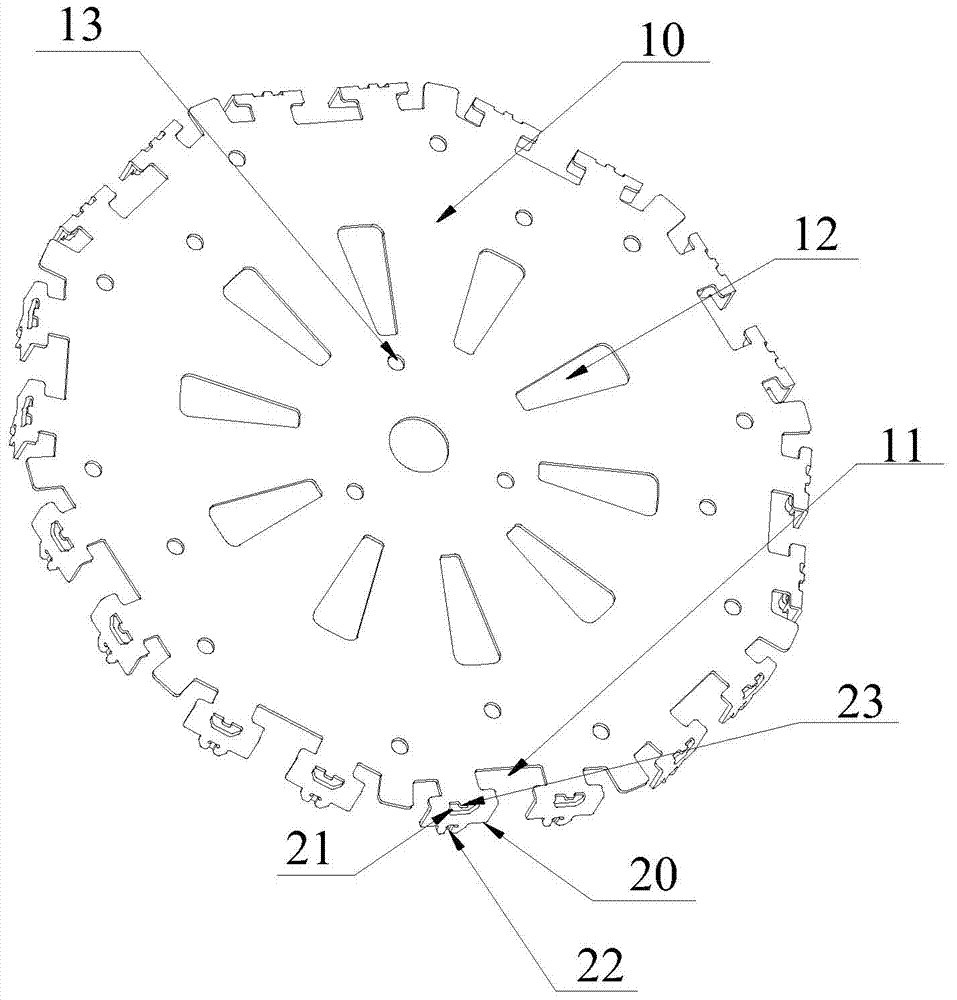

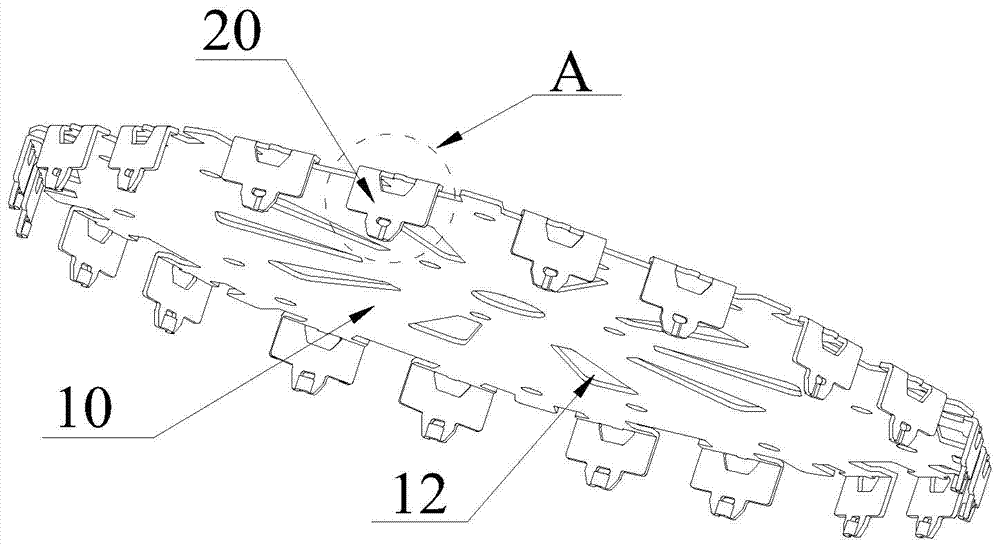

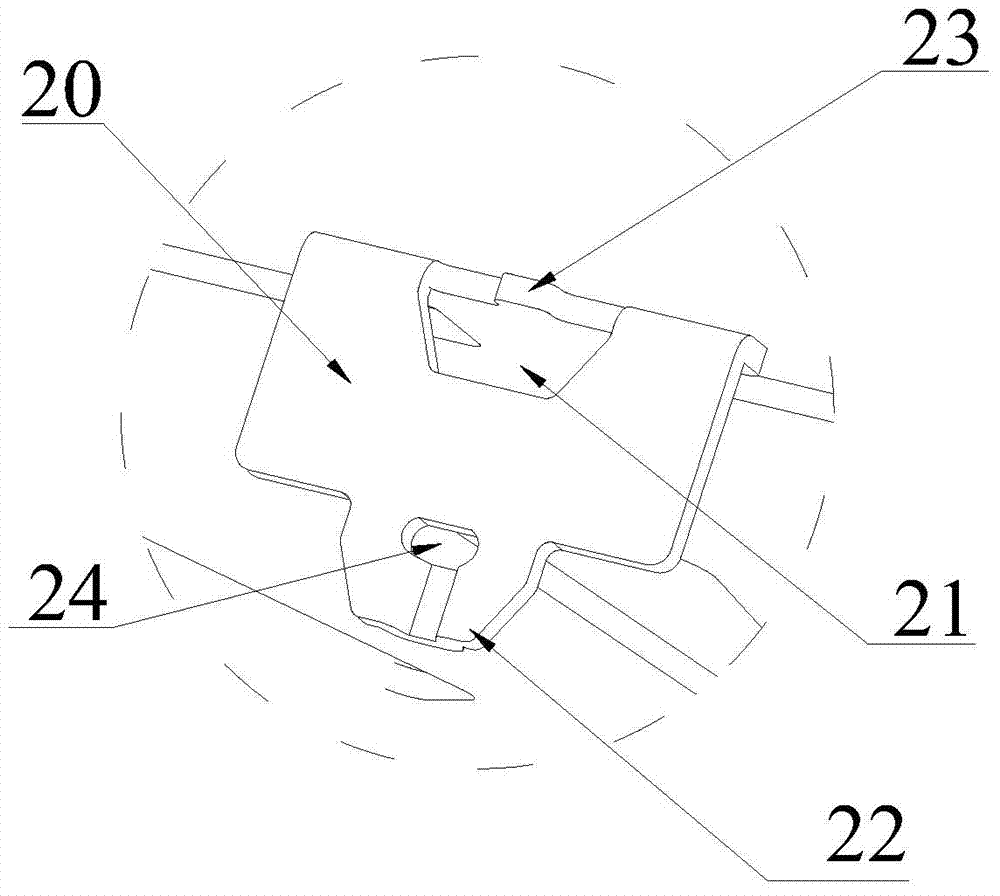

[0035] refer to Figure 1 to Figure 7 , an embodiment of the heat sink of the present invention is proposed, the heat sink is columnar, and is formed by stacking and assembling a plurality of heat sinks 10 produced separately. The heat sink 10 is arranged in a regular polygon, and several connecting fins 20 are vertically arranged on the edge of the heat sink 10. The positions of the connecting fins 20 on the laminated heat sinks 10 are aligned, and the connecting fins 20 are used for the connection between the laminated heat sinks 10. . The connecting sheet 20 is formed by extending vertically downward along the edge of the heat sink 10 , and integrally formed with the heat sink 10 . A notch 21 with an open upper end is provided on the upper part of the connecting piece 20 . The notch 21 is formed by cutting downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com