LED lighting lamp

A technology for LED lighting and LED modules, applied in lighting devices, lighting and heating equipment, cooling/heating devices for lighting devices, etc. Reduced capital investment, enhanced heat dissipation capability, and the effect of small radiators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention realizes the 9W G60 non-magnetic component, no electrolysis, drive integrated light-emitting board, small heat sink, high PF, low harmonic, high-life dimmable LED wide-light bulb lamp scheme.

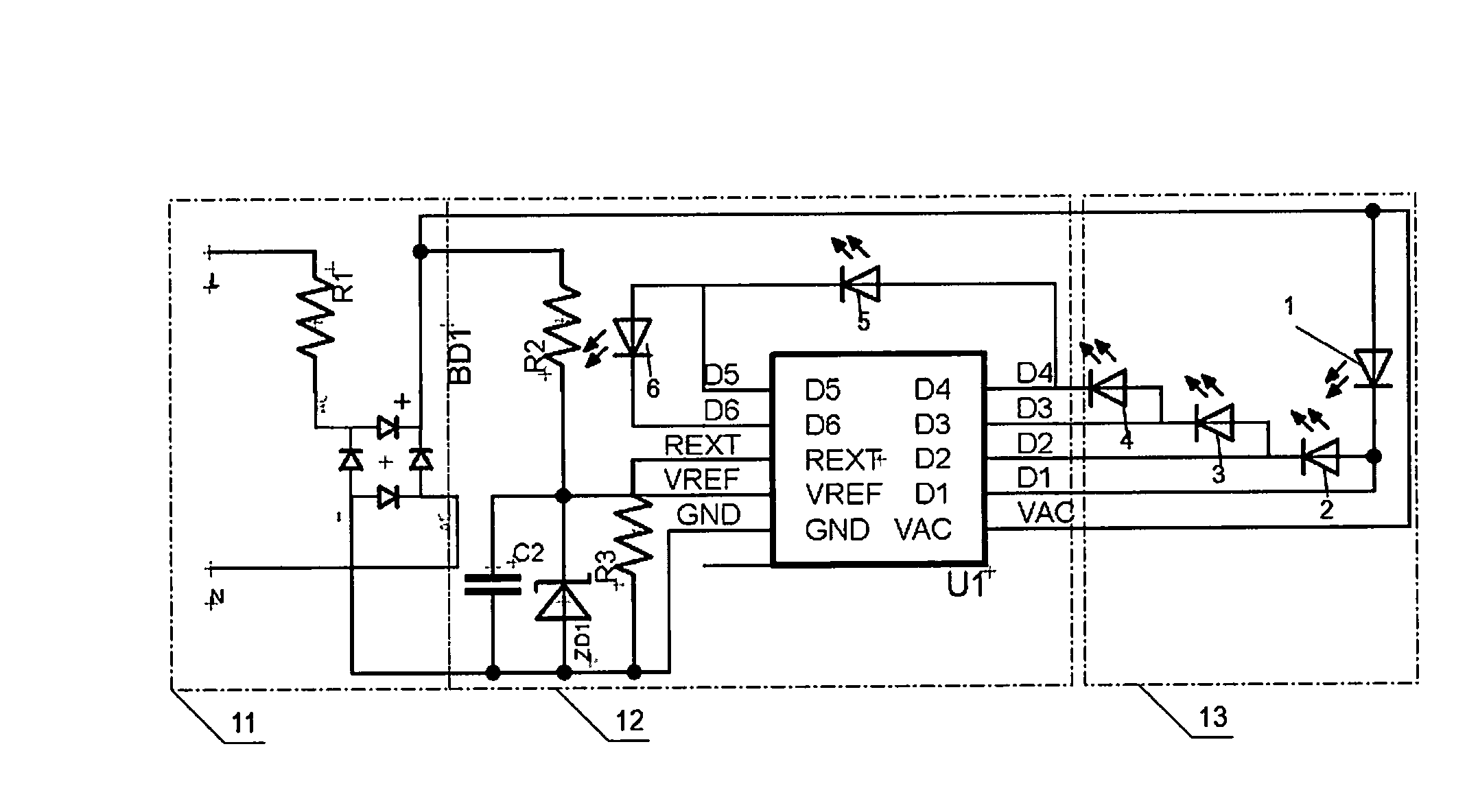

[0025] Such as figure 1 As shown, the LED lighting fixture of the present invention includes an AC-DC rectification circuit 11, a constant current control circuit 12 and an LED module group 13; the AC-DC rectification circuit 11 includes an AC input terminal AC_L&AC_N, a protection overcurrent device R1, a full-bridge rectifier circuit BD1 that converts the input power frequency alternating current into pulsating direct current; the constant current control loop 12 includes a subsection start control circuit, a pulse constant current control circuit U1 and a constant current The limiting circuit, the subsection start control circuit is composed of the second resistor R2, the Zener diode ZD1, and the second capacitor C2, and the constant current limiting circuit is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com