Large-inclination-angle coal bed fully-mechanized mining bracket and support method

A technology of fully mechanized mining support and large inclination angle, applied in the direction of mine roof support, mining equipment, earthwork drilling, etc., can solve the problems of impact damage to the shielding support, the overall sliding of the shielding support, etc., and achieve the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

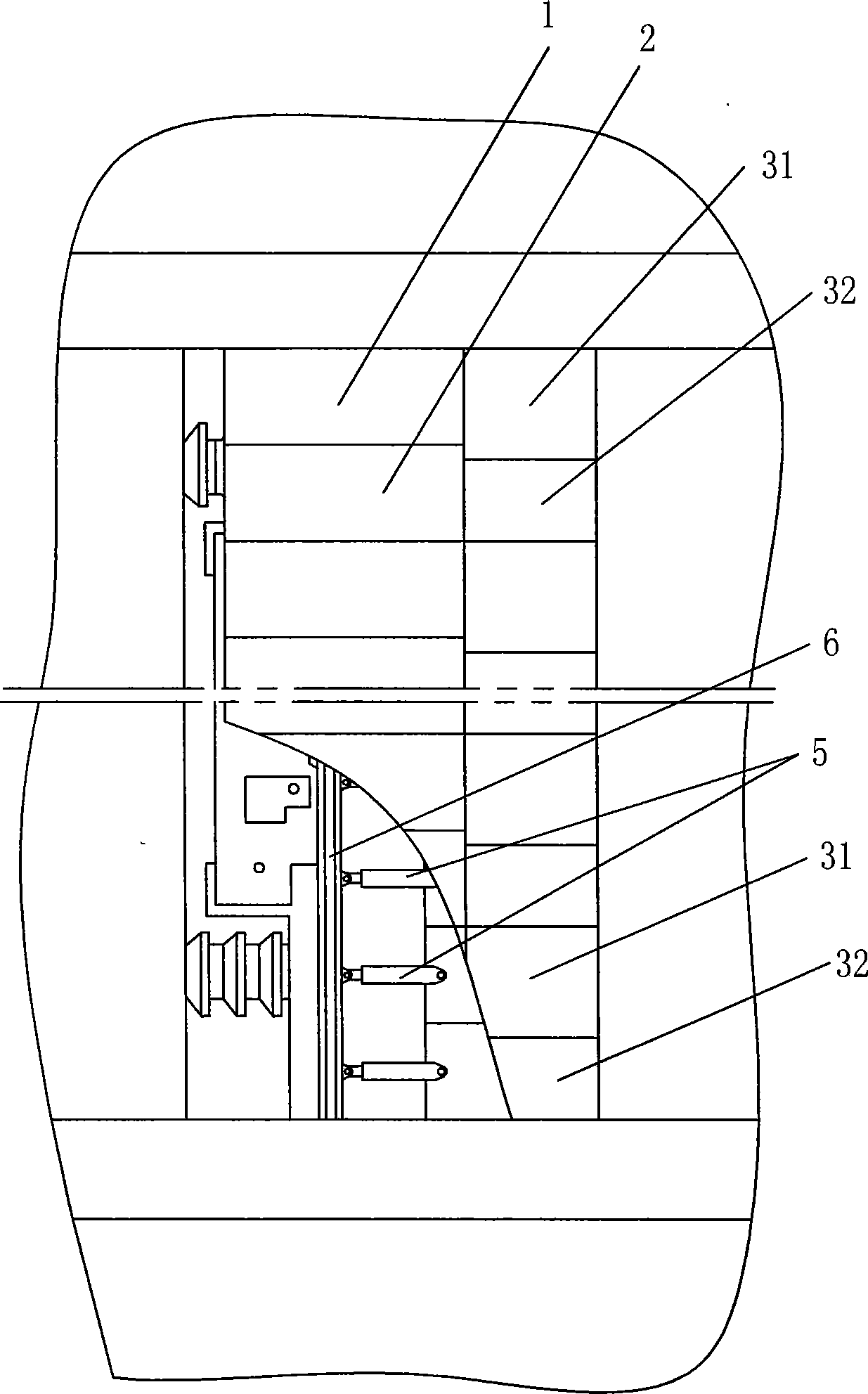

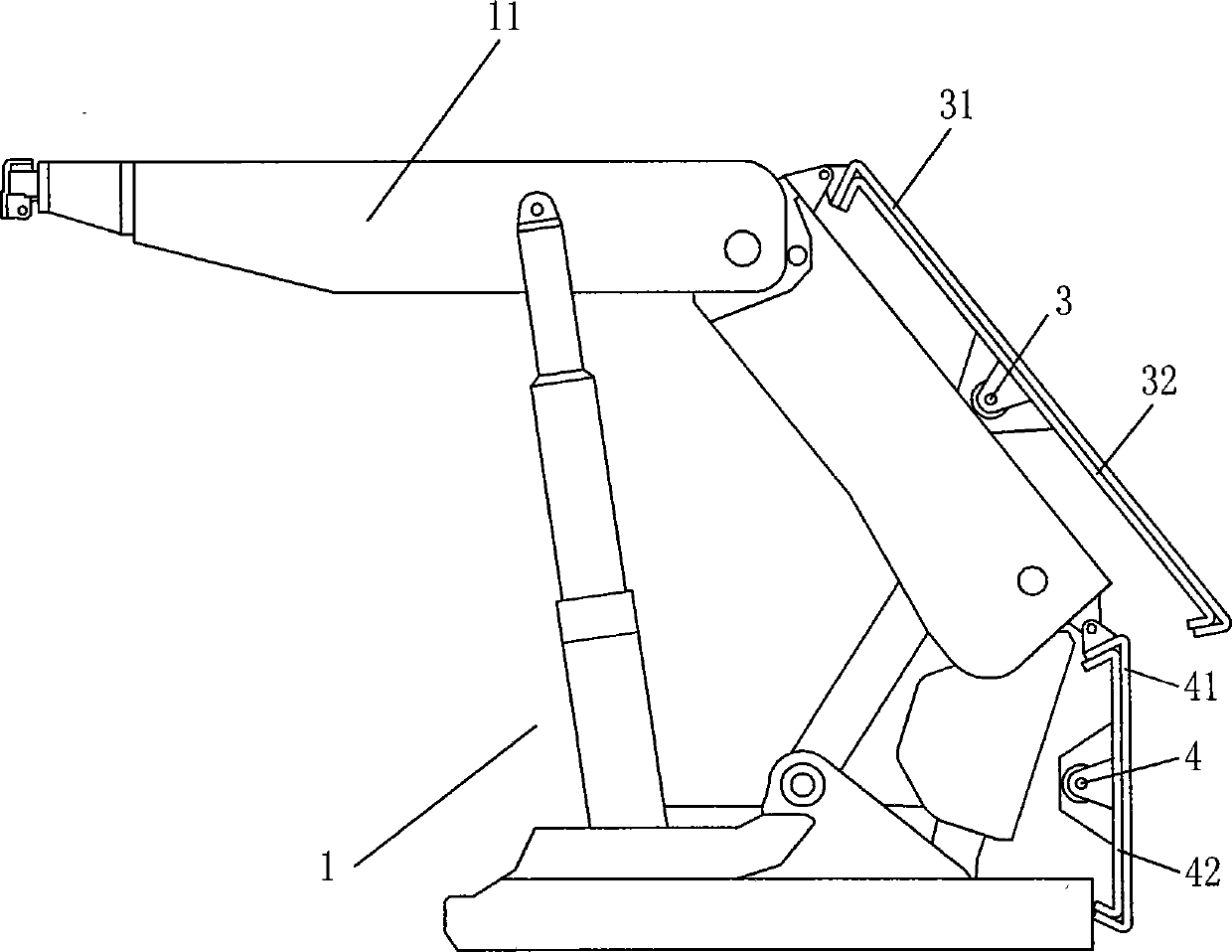

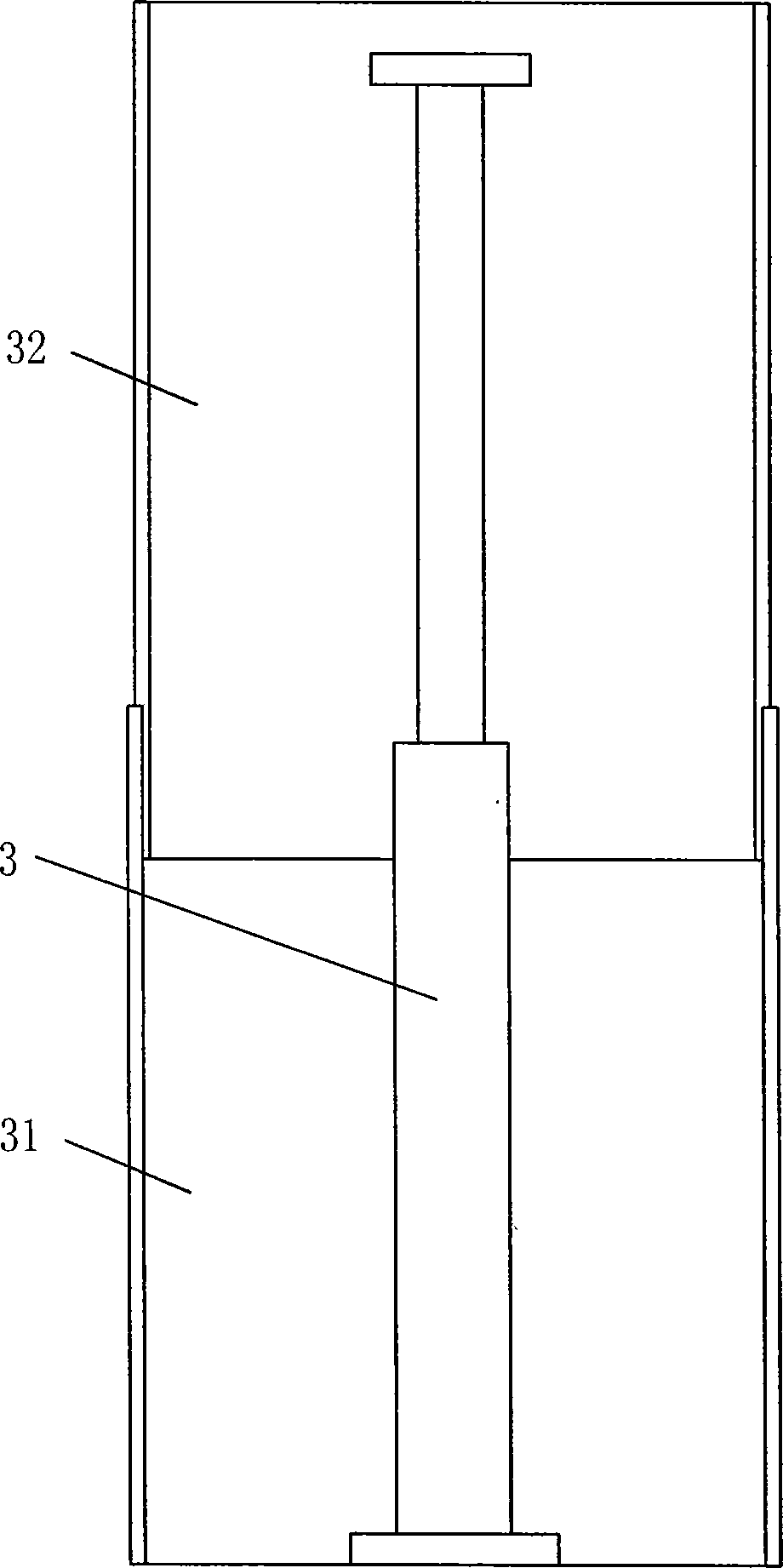

[0024] Example 1, see figure 1 , figure 2 , image 3, a fully-mechanized coal mining support with a large dip angle, the fully-mechanized mining support is composed of a first hydraulic support 1 and a second hydraulic support 2 in pairs, the first hydraulic support 1 is located above the second hydraulic support 2, and the rear of the first hydraulic support 1 The end is provided with a gangue retaining device, the gangue retaining device is composed of an upper gangue retaining wall and a lower gangue retaining wall, the upper gangue retaining wall is hinged on the upper end of the upper link 12 hinged with the top beam 11 on the first hydraulic support 1, and the lower retaining wall The gangue wall is hinged at the lower end of the upper connecting rod 12, and the lower gangue wall is located in front of the upper gangue wall. When the top beam 11 of the first hydraulic support 1 supports the roof of the coal mining face, the upper gangue wall and the lower gangue wall ...

Embodiment 2

[0026] Example 2, see figure 1 , figure 2 , image 3 , a fully mechanized mining support method for a large dip angle coal seam, comprising the following steps:

[0027] S1. Lay out the cover support: set a plurality of fully mechanized coal mining supports with a large inclination angle described in Embodiment 1 in the fully mechanized coal mining working face with a large inclination angle, so that the gangue blocking device at the rear end of the first hydraulic support 1 is located behind the second hydraulic support 2, And form a block to the gangue in the goaf behind the first hydraulic support 1 and the second hydraulic support 2, and respectively connect the first hydraulic support 1 and the second hydraulic support 2 with the chute 6 of the coal mining equipment through the propelling cylinder 5;

[0028] S2. Support: lift the top beam 3 of the first hydraulic support 1 and the second hydraulic support 2 through the lifting cylinder respectively, so that the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com