Down-hole steam injection string of thick-oil thermal production well

A heavy oil thermal recovery and steam pipe technology, which is used in wellbore/well components, production fluids, earth-moving drilling, etc. problems, to achieve the effect of improving the oil-steam ratio, improving the quality of steam injection, and improving the effect of steam injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

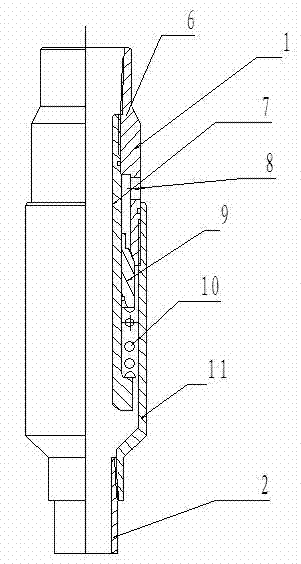

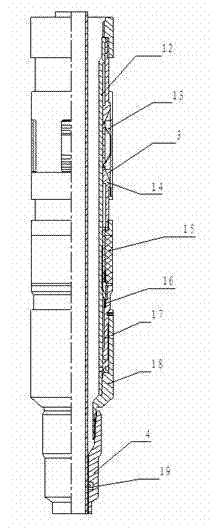

[0012] The present invention is described in detail below in conjunction with accompanying drawing, see figure 1 , figure 2 with image 3 A downhole steam injection string in a heavy oil thermal recovery well includes a thermal insulation tube and a suspension packer 3, the thermal insulation tube, a backwash valve 1 and a sealed telescopic tube 2 are sequentially connected to form an inner steam injection string; the suspension packer 3 is sequentially connected with the sealing sleeve 4 and the switch assembly 5 to form the steam injection outer pipe string; the suspension packer 3 of the steam injection outer pipe string is seated and suspended on the inner wall of the casing, and the sealing and expansion of the steam injection inner pipe string The pipe 2 is inserted into the switch assembly 5 of the steam injection outer column and can slide in the sealing sleeve 4 . The sealing telescopic tube 2 includes a sliding tube and a clamp claw 23, and the upper part of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com