Slit type 00Cr9MoNi alloy steel sand prevention pipe

A technology of sand control pipe and alloy steel, which is applied in the development of fluids, wellbore/well components, and earth-moving drilling, etc., can solve the problems of restricting the ultimate recovery rate of oil wells, low production time rate of oil wells, and short period of sand control pipes, etc. Improve sand control efficiency and construction efficiency, prolong the pumping cycle, and avoid the effects of sand stuck and sand burial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

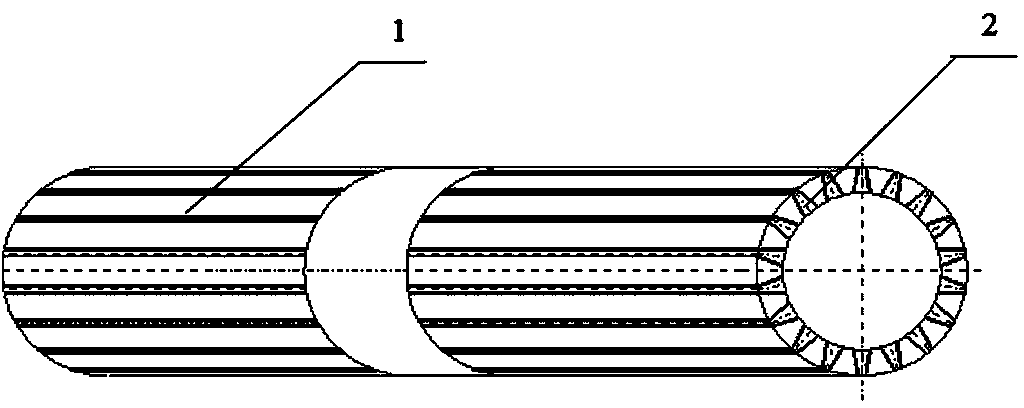

[0015] In order to further disclose the technical solution of the invention, the following will be described in detail through the embodiments in conjunction with the accompanying drawings:

[0016] The present invention includes a sand control pipe body 1 and a sand filter seam 2, which is characterized in that the sand control pipe body is set as a circular tube, made of 00Cr9MoNi alloy steel material, and the body is segmented from the outer circumference to the inner circumference and cut with a laser gun. Trapezoidal sand filter joint with small opening and large inner opening, the interval between each section is 30-50mm, the length of each section is 3-5m, the width of the outer opening of the trapezoidal sand filtering joint is 0.05-0.30mm, and the thickness of the outer opening is 0.3-0.5 mm, taper pipe male threads are provided at both ends of the sand control pipe.

[0017] When applying the present invention, use the operation pipe string to lower it into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com