Dry-process polyimide spinning oil

A dry spinning, polyimide technology, applied in textile and papermaking, fiber processing, fiber type and other directions, can solve problems such as poor unwinding, poor tow bundles, etc., to achieve reasonable formula, low production cost, Solve the effect of large static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1, a kind of polyimide dry-process spinning oil, is made up of the raw material of following proportion by weight, is made up of the raw material of following proportion by weight, 36 parts of simethicone oil, 13 parts of refined mineral oil 5 parts, 5 parts of sorbitan monooleate polyoxyethylene ether, 7 parts of lauryl phosphate diethanolamine salt, 10 parts of potassium cetyl phosphate, and 15 parts of fatty alcohol polyoxyethylene ether. Mix simethicone and refined mineral oil evenly, heat up to 40°C, add sorbitan monooleate polyoxyethylene ether, stir for 30 minutes, heat up to 60°C, add cetyl potassium phosphate and fatty alcohol Stir polyoxyethylene ether for 20 minutes, cool down to 40°C, add dodecyl phosphate diethanolamine salt, continue stirring for 40 minutes, then cool to 25°C to obtain polyimide dry spinning oil.

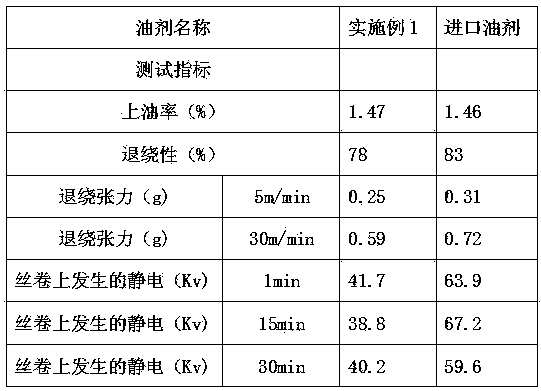

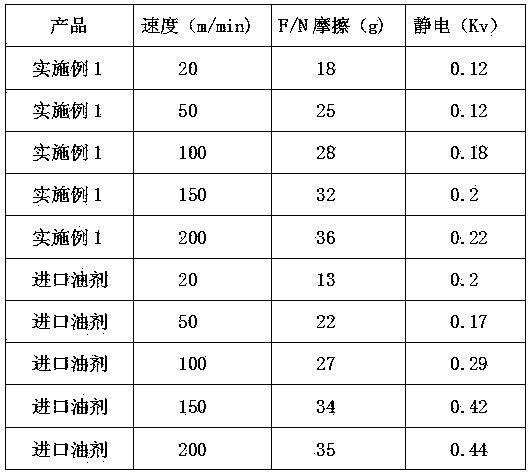

[0012] Embodiment 1 is compared with the polyimide dry spinning oil agent imported from Japan, and the measured data of the oil agen...

Embodiment 2

[0023] Embodiment 2, a kind of polyimide dry-process spinning oil, is made up of the raw material of following proportion by weight, 30 parts of simethicone oil, 30 parts of refined mineral oil, sorbitan monooleate poly 3 parts of oxyethylene ether, 10 parts of dodecyl phosphate diethanolamine salt, 8 parts of potassium hexadecyl phosphate, 20 parts of fatty alcohol polyoxyethylene ether.

Embodiment 3

[0024] Example 3, a polyimide dry spinning oil, 60 parts of simethicone oil, 10 parts of refined mineral oil, 9 parts of sorbitan monooleate polyoxyethylene ether, lauryl phosphoric acid 5 parts of ester diethanolamine salt, 14 parts of potassium cetyl phosphate, and 10 parts of fatty alcohol polyoxyethylene ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com