Method for preventing sulphureous gear steel SAE8620H from clogging nozzle

A SAE8620H, gear steel technology, applied in the field of thermodynamic equilibrium, can solve the problem of high melting point CaS blocking the nozzle and other problems, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

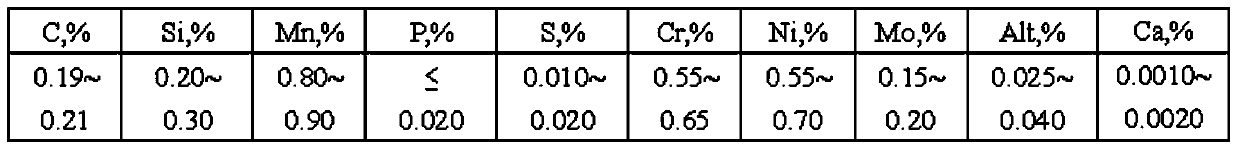

example 1

[0025] Example 1: Key parameters of casting SAE8620H steel process. Molten steel C: 0.21%, Si: 0.25%, Mn: 0.87%, P: 0.011%, S: 0.020%, Alt: 0.028%, Cr: 0.51%, Ni: 0.17%, Mo: 0.58%, Ca: 0.0019% .

[0026] Tundish temperature: 1535°C. Where [Ca] / [Al]t=0.07, [Ca] / [S]=0.09, [O]: 0.0008%. The casting of 210 tons of molten steel went smoothly without clogging the nozzle.

example 2

[0027] Example 2: Key parameters of casting SAE8620H steel process. Molten steel C: 0.20%, Si: 0.26%, Mn: 0.88%, P: 0.014%, S: 0.018%, Alt: 0.027%, Cr: 0.52%, Ni: 0.17%, Mo: 0.60%, Ca: 0.0016% .

[0028] Tundish temperature: 1538°C. Where [Ca] / [Al]t=0.06, [Ca] / [S]=0.08, [O]: 0.0009%. The casting of 210 tons of molten steel went smoothly without clogging the nozzle.

example 3

[0029] Example 3: Key parameters of casting SAE8620H steel process. Molten steel C: 0.20%, Si: 0.25%, Mn: 0.88%, P: 0.012%, S: 0.019%, Alt: 0.03%, Cr: 0.50%, Ni: 0.16%, Mo: 0.58%, Ca: 0.0018% .

[0030] Tundish temperature: 1537°C. Where [Ca] / [Al]t=0.06, [Ca] / [S]=0.09, [O]: 0.0006%. The casting of 210 tons of molten steel went smoothly without clogging the nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com