Method of improving quality of welding wire steel casting blank

A technology of welding wire steel and billet, which is applied in the field of improving the quality of welding wire steel billet, can solve problems affecting the quality of billet, scarring on the surface of billet, welding spatter, etc., and achieve excellent drawing performance and welding performance, and purity The effect of improving castability and reducing slab cleaning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

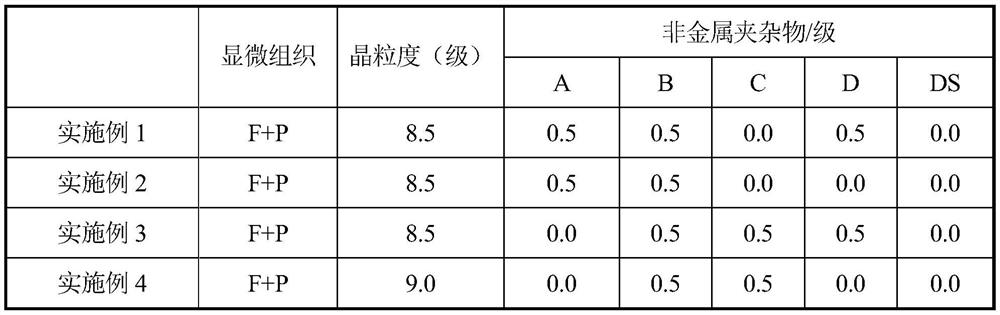

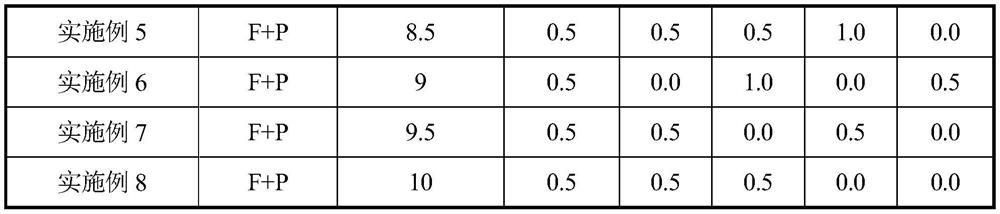

[0034] In the specific implementation process, the method for improving the quality of BZJ60-Ti welding wire steel casting billet of the present invention includes the following processes:

[0035] The production process of BZJ60-Ti welding wire steel casting billet: mixing furnace-hot metal pretreatment (S removal, slagging)-120 tons converter (top and bottom blowing)-ladle bottom argon blowing-LF furnace refining-150*150mm square Billet continuous casting.

[0036] BZJ60-Ti gas shielded welding wire is mainly used for the welding of high-quality carbon steel and low-alloy high-strength steel, which requires the tensile strength of the weld metal and good toughness. At the same time, the welding wire should have less spatter, stable arc and good weld formability. It should be said that these requirements can only be met by strictly controlling the chemical composition of steel and purifying steel. In response to these requirements, the composition control of BZJ60-Ti welding wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com