Method for extracting gardenia oil by using subcritical fluid

A subcritical fluid, gardenia oil technology, applied in the direction of edible oil/fat, application, fat oil/fat production, etc., can solve the problems of low efficiency of gardenia oil, poor quality of gardenia oil, poor safety, etc., to achieve safety High performance, low production cost and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

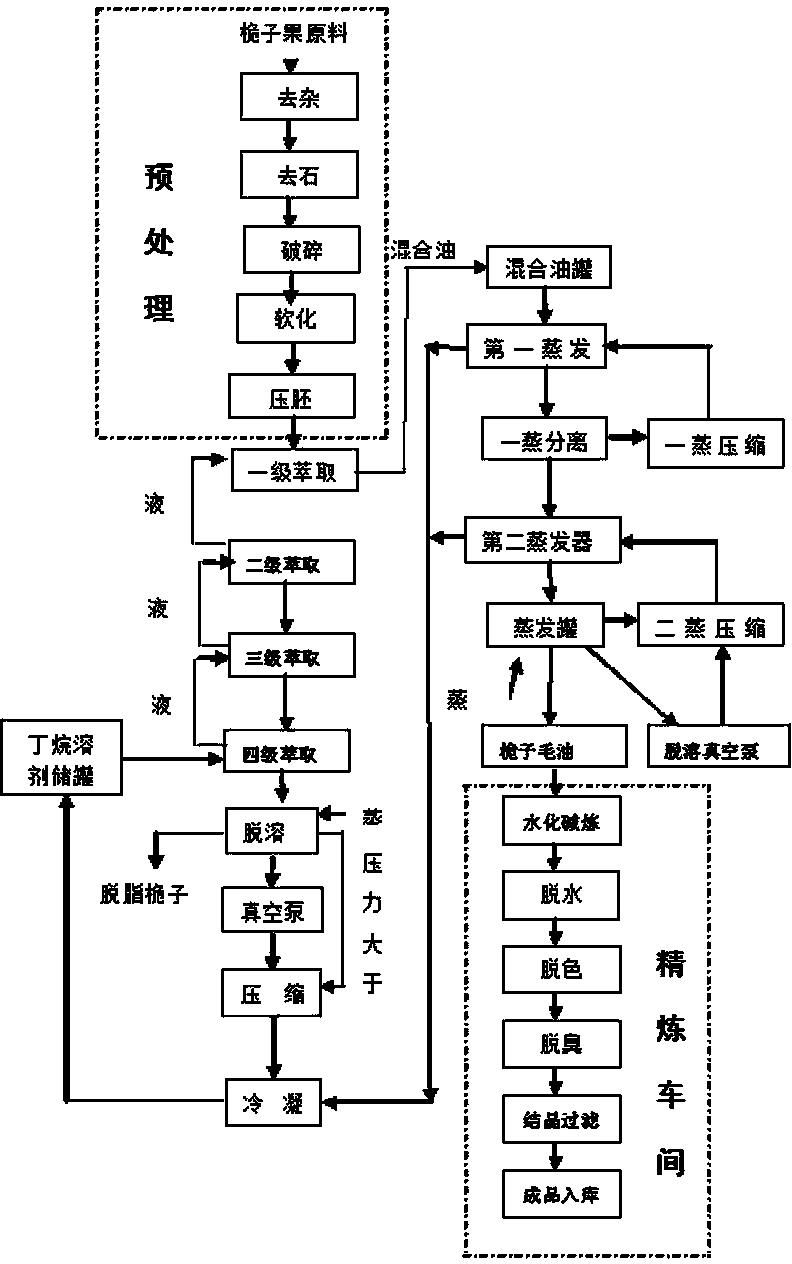

[0031] see figure 1 , a method for extracting gardenia oil with a subcritical fluid, comprising the steps of:

[0032] (1) The raw materials of gardenia fruit are pretreated by removing impurities, removing stones, crushing, softening, and pressing embryos in sequence, and putting the pretreated gardenia fruit raw materials into the extraction tank;

[0033] (2) Check the airtightness of the extraction tank. After ensuring that the airtightness is good, use a delivery pump to input liquid butane into the extraction tank for leaching according to the solid-to-liquid mass ratio of 1:4;

[0034] (3) Four stages of leaching and extraction are carried out in each tank, and the leaching time of each stage is two hours. The liquid enters the upper stage of extraction respectively, and the first stage extract is separated;

[0035] (4) The first-stage extract enters the evaporator for decompression evaporation and desolventization, and makes gardenia crude oil. At the same time, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pulverization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com