Ferric oxide oily color paste

A technology of iron oxide oil and iron oxide, which is applied in the direction of cosmetics, cosmetics, pigment paste, etc., can solve the problems of inconvenient and safe use, easy aggregation of iron oxide powder, poor waterproof performance, etc., and improve the use safety and improve Excellent effect of lipophilicity and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

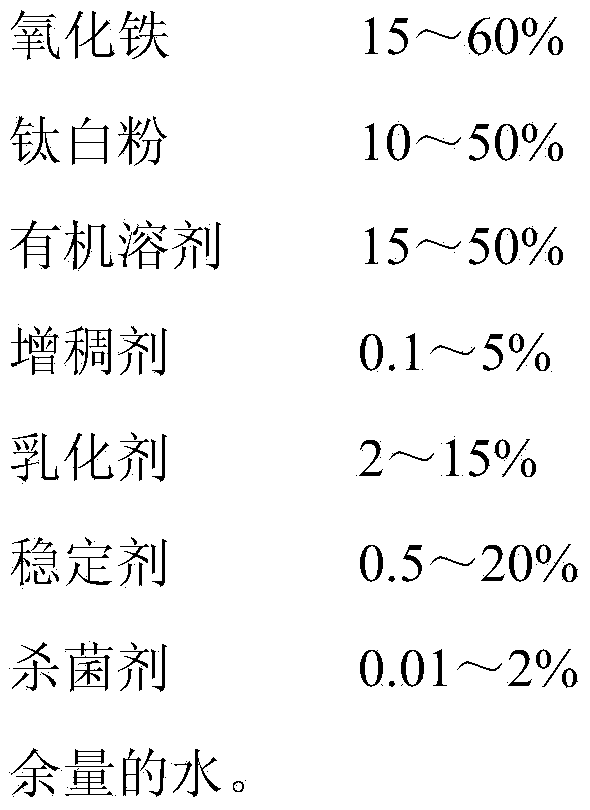

[0037] The formula of the iron oxide oily color paste of the present embodiment is as follows:

[0038]

[0039] The preparation method of the iron oxide oily color paste of the present embodiment is as follows:

[0040] (1) Take described iron oxide red, rutile type titanium dioxide, polydimethylsiloxane, organobentonite, PEG-10 polydimethylsiloxane, cetyl trimethyl chloride by weight percentage ammonium chloride, mixed, heated and stirred at 50°C to obtain a uniformly dispersed oil phase;

[0041] (2) Magnesium sulfate heptahydrate and water of the corresponding weight are mixed, heated and stirred at 50° C. to obtain a uniform and transparent water phase;

[0042] (3) Add the water phase obtained in step (2) into the oil phase obtained in step (1), and stir rapidly to obtain the iron oxide oily color paste.

[0043] The iron oxide oily color paste prepared according to the above method is red, has good fluidity, is convenient to use, and does not generate dust. The co...

Embodiment 2

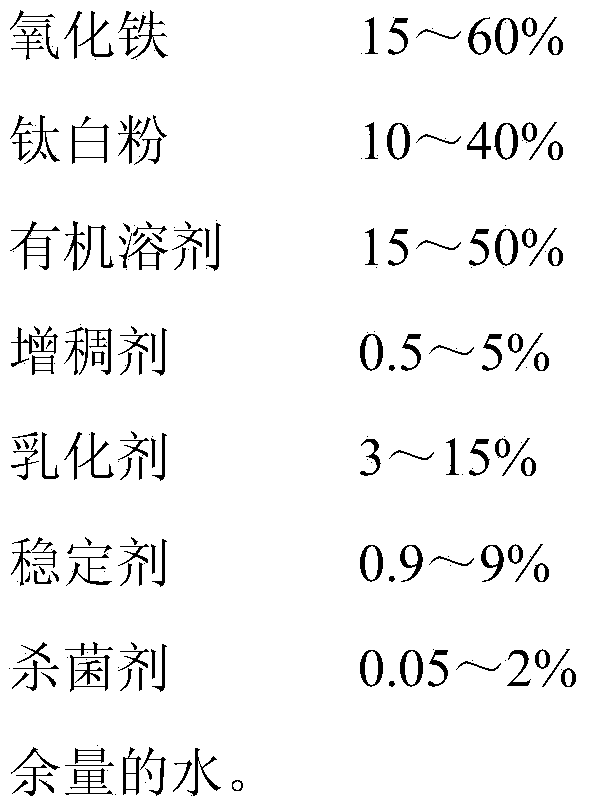

[0045] The formula of the iron oxide oily color paste of the present embodiment is as follows:

[0046]

[0047] The preparation method of the iron oxide oily color paste of the present embodiment is as follows:

[0048] (1) Weigh the iron oxide black, rutile titanium dioxide, octamethylcyclotetrasiloxane, calcium stearate, PEG-10 polydimethylsiloxane, octadecyltrimethylsiloxane, etc. Methyl ammonium chloride, mixed, heated and stirred at 50°C to obtain a uniformly dispersed oil phase;

[0049] (2) Mix corresponding weights of 1,2-butanediol and water, heat and stir at 50°C to obtain a uniform and transparent water phase;

[0050](3) Add the water phase obtained in step (2) into the oil phase obtained in step (1), and stir rapidly to obtain the iron oxide oily color paste.

[0051] The iron oxide oily color paste prepared according to the above method is black, has good fluidity, is convenient to use, and does not generate dust. The contact angle between water droplets a...

Embodiment 3

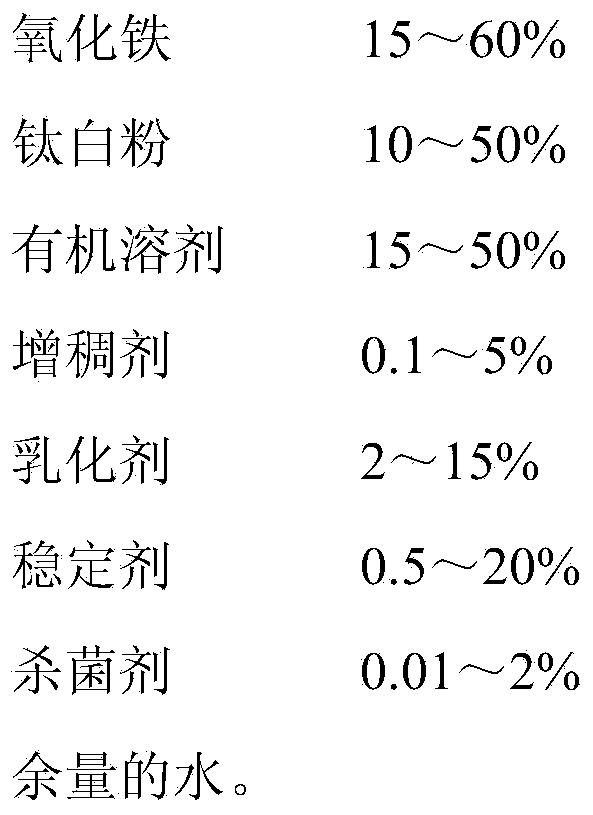

[0053] The formula of the iron oxide oily color paste of the present embodiment is as follows:

[0054]

[0055]

[0056] The preparation method of the iron oxide oily color paste of the present embodiment is as follows:

[0057] (1) Take described iron oxide yellow, anatase titanium dioxide, jojoba seed oil, magnesium stearate, cetyl PEG / PPG-10 / 1 dimethylsiloxane, clove essential oil by weight percentage , mixed, heated and stirred at 55°C to obtain a uniformly dispersed oil phase;

[0058] (2) Mix glycerol and water of corresponding weight, heat and stir at 55° C. to obtain a uniform and transparent water phase;

[0059] (3) Add the water phase obtained in step (2) into the oil phase obtained in step (1), and stir rapidly to obtain the iron oxide oily color paste.

[0060] The iron oxide oily color paste prepared by the above method is yellow, has good fluidity, is convenient to use, and does not generate dust. The contact angle between water droplets and the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com