High-fluidity polylactic acid-based wood-plastic injection molding composite material and preparation method thereof

A composite material and high fluidity technology, applied in the field of degradable polylactic acid-based wood-plastic composite materials, can solve problems such as poor interface compatibility, achieve favorable processing and molding, reduce burning, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

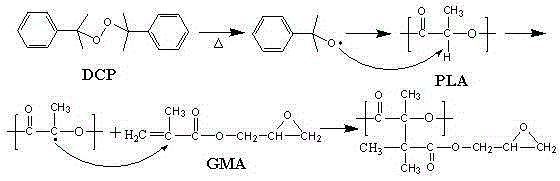

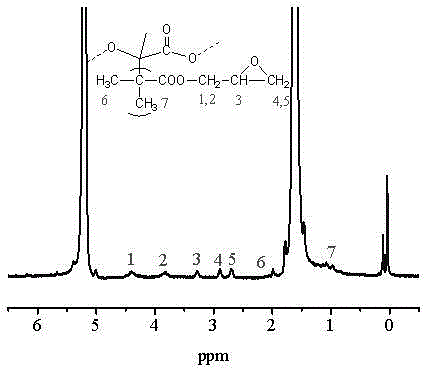

[0029] A preparation method of a graft copolymer of polylactic acid-glycidyl methacrylate: add 20 g of dried polylactic acid into a flask containing 100 mL of DMF, feed nitrogen, and add 2 g of glycidyl methacrylate and 0.1 g DCP initiator. The reaction was placed in a microwave reactor with a microwave power of 400W, and the reaction was stirred for 10 minutes. Precipitate with ethanol, filter and dry to obtain the compatibilizer.

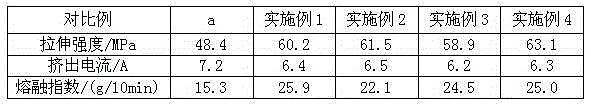

[0030] Mix poplar wood fiber (80-mesh poplar wood powder, the same below), polylactic acid, polycaprolactone, lubricant and compatibilizer according to the mass ratio of 50 / 50 / 10 / 1 / 10, add the twin-screw In the silo of the extruder, the temperature of the screw is set to 170° C., and the rotational speed of the screw is 150 rpm. The extrudate is cooled and pelletized to obtain composite material particles.

Embodiment 2

[0032] The preparation method of the graft copolymer of polylactic acid-glycidyl methacrylate: add 20 g of dried polylactic acid into a flask containing 120 mL of DMF, blow nitrogen into the system, and add 4 g of glycidyl methacrylate and 0.15 g of DCP Initiator. The reaction was placed in a microwave reactor with a microwave power of 600W, and the reaction was stirred for 15 minutes. Precipitate with ethanol, filter and dry to obtain the compatibilizer.

[0033] Poplar wood fiber, polylactic acid, polycaprolactone, lubricant and compatibilizer are mixed according to the ratio of 50 / 50 / 10 / 1 / 5 by mass, and added to the silo of the twin-screw extruder, and the screw temperature is set to 195°C, screw speed 280rpm. The extrudate is cooled and pelletized to obtain composite material particles.

Embodiment 3

[0035]A preparation method of a graft copolymer of polylactic acid-glycidyl methacrylate: a preparation method of a graft copolymer of polylactic acid-glycidyl methacrylate: add 20 g of dried polylactic acid into a flask containing 80 mL of DMF , nitrogen gas was passed into the system, and 1.5 g of glycidyl methacrylate and 0.15 g of BPO initiator were added to the system. The reaction was placed in a microwave reactor with a microwave power of 400W, and the reaction was stirred for 12 minutes. Precipitate with ethanol, filter and dry to obtain the compatibilizer.

[0036] Poplar wood fiber, polylactic acid, polycaprolactone, lubricant and compatibilizer are mixed according to the ratio of 50 / 45 / 5 / 2 / 13 by mass, and added to the silo of the twin-screw extruder, and the screw temperature is set to 180°C, screw speed 260rpm. The extrudate is cooled and pelletized to obtain composite material particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com