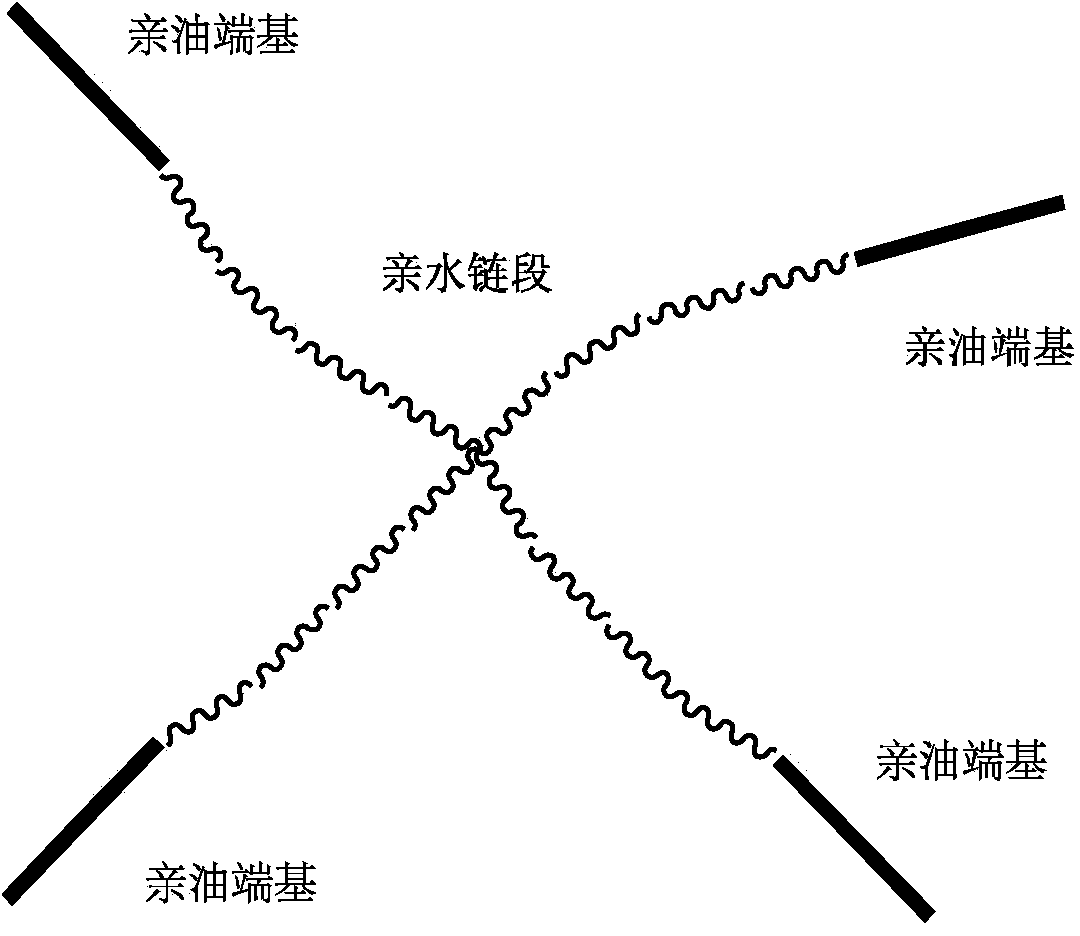

Preparation method of linear and star polyethylene associated thickening agent

An associative thickener and polyurethane technology, applied in the direction of adhesive additives, polymer adhesive additives, coatings, etc., can solve problems such as complex process, difficult reaction control, high temperature sensitivity, etc., and achieve high sensitivity The effect of low cost, simple process and large tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

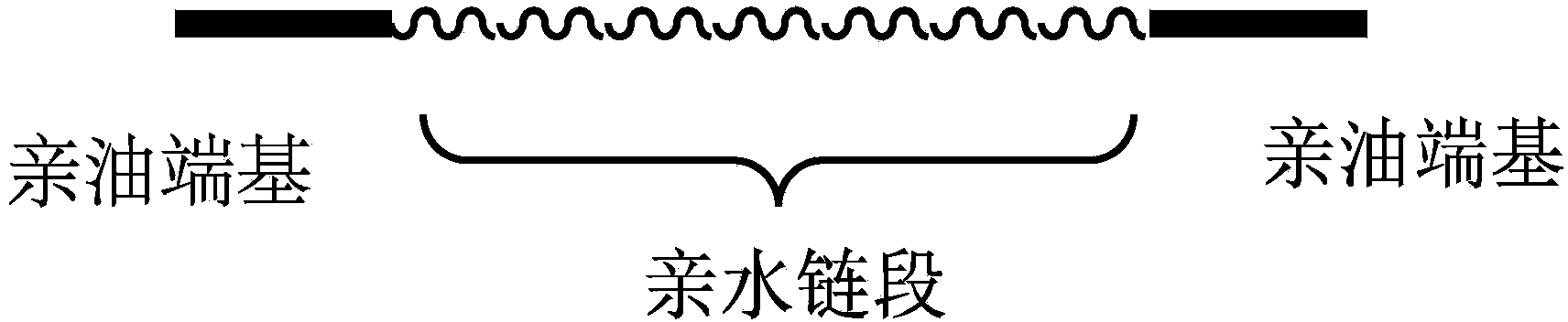

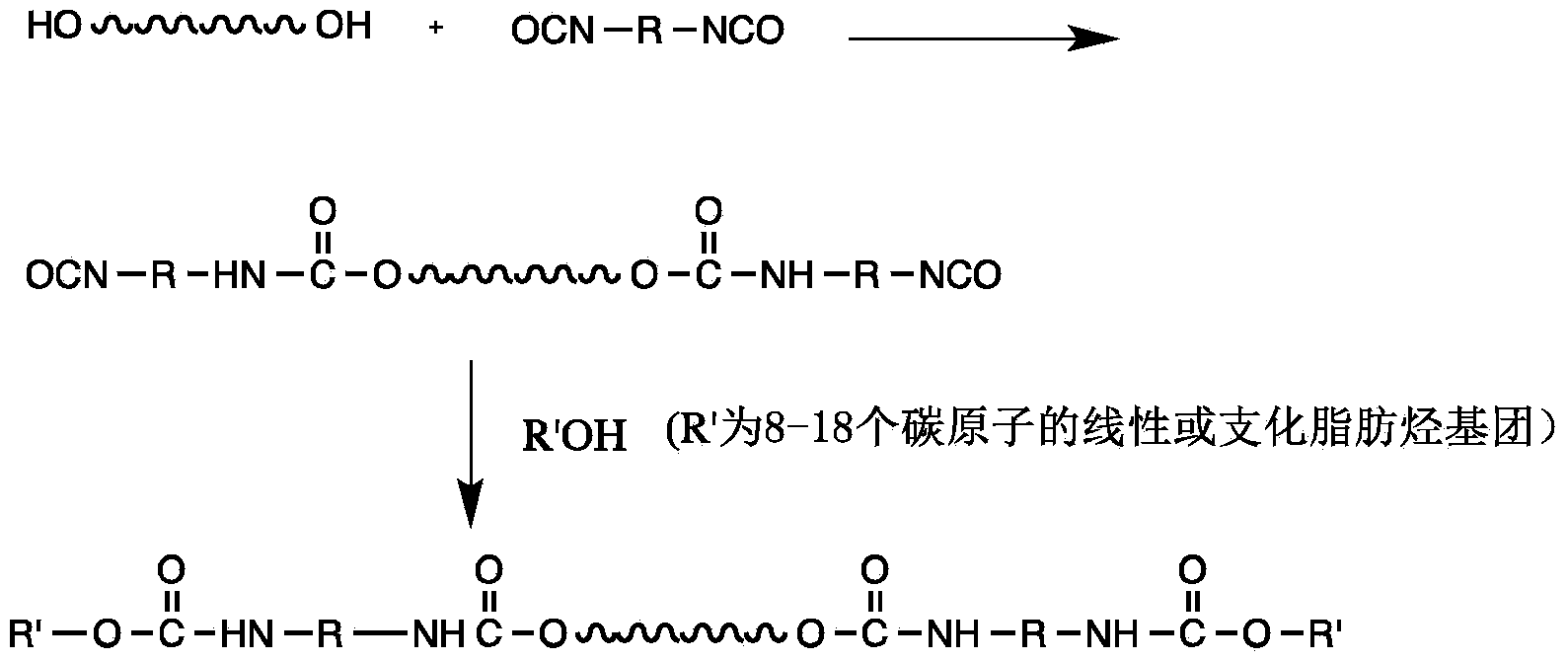

[0032] Synthesis of Linear Polyurethane Associative Thickener

[0033] Add 61 parts of commercially available linear polyethylene glycol 6000 (number average molecular weight 6100) into a reaction flask equipped with stirring, a thermometer and a distillation device, dehydrate in vacuum at 105°C-120°C for 1-3 hours, cool to 80°C and add 6 Part of octadecyl isocyanate, react at 80°C-110°C for 3-5 hours, after the reaction, according to the required final product form, it can be directly out of the kettle, after the material is cooled, crushed and milled to obtain 100% polyurethane associative The thickener is dry powder, and water / ethylene glycol monobutyl ether mixed solvent can also be added to dilute the reactant to obtain various concentrations of polyurethane associative thickener solutions. It can also be diluted with pure water, and non-ionic surfactants such as isooctyl polyoxyethylene ether can be added to control the viscosity of the product to obtain a solvent-free p...

example 2

[0035] Synthesis of three-arm star polyurethane associative thickener

[0036] Add 1.34 parts of initiator trimethylolpropane and 1.7 parts of KOH into the reaction bottle, install a fractionation column, heat in an oil bath, and vacuum dehydrate at 75°C-85°C for 3-4h under stirring to prepare the initiator. Move the prepared initiator into a polymerization kettle that has been dried and heated to 110°C-130°C, vacuum fill N2 for replacement 3 times, and gradually introduce 120 parts of ethylene oxide (EO) for reaction. By controlling the amount of EO feed and The amount of cooling water is used to adjust the temperature of the system to react at 110°C-130°C and 0.4MPa-0.6MPa. After EO is fed, continue to react for 1 hour, ventilate, remove unreacted EO in vacuum, and then discharge at about 95°C. The product was diluted with water, ion-exchanged, and dried to obtain an intermediate product. The hydroxyl value was determined to be 16.0, the molecular weight was determined to be...

example 3

[0039] Synthesis of six-arm star polyurethane associative thickener

[0040] Add 1.82 parts of initiator D-sorbitol and 3.4 parts of KOH into the reaction bottle, install a fractionation column, heat in an oil bath, and vacuum dehydrate at 75°C-85°C for 3-4h under stirring to prepare the initiator. Move the prepared initiator into a polymerization kettle that has been dried and heated to 110°C-130°C, vacuum-fill N2 for 3 times, and gradually introduce 190 parts of ethylene oxide (EO) for reaction. By controlling the amount of EO feed and The amount of cooling water is used to adjust the temperature of the system to react at 110°C-130°C and 0.4MPa-0.6MPa. After EO is fed, continue to react for 1 hour, ventilate, remove unreacted EO in vacuum, and then discharge at about 95°C. The product was diluted with water, ion-exchanged, and dried to obtain an intermediate product. Its hydroxyl value was determined to be 17.1, its molecular weight was determined to be 19500 by GPC, and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com