A method and system for thickening the whole tailings slurry paste

A technology of full tailings and slurry, applied in separation methods, chemical instruments and methods, solid waste management, etc., can solve the problems of low dense concentration, high overflow concentration, low dehydration efficiency, etc., and achieve reliable operation of equipment, dense High efficiency and high promotional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

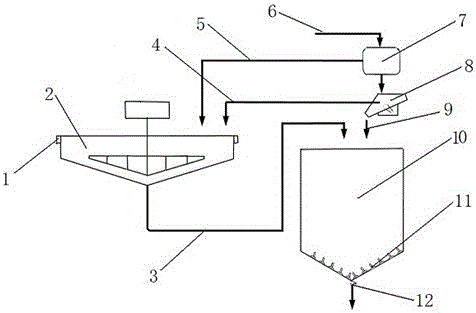

Embodiment 1

[0029]Example 1 This system is applied in a metal mine, the tailings -200 mesh content is 48%, the whole tailings slurry with a concentration of 20% discharged from the dressing plant is transported to the cyclone, and the cyclone generally uses a small-angle cone Or a multi-cone structure cyclone, the classification limit of the cyclone is -19μm, and the whole tailings slurry is divided into fine-grained tailings mortar and coarse-grained tailings mortar, and the underflow of the cyclone is thickened coarse-grained tailings Mortar, with a concentration of 65%, completes the first thickening, and is discharged to the vibrating screen. The vibrating screen adopts a dual-motor self-synchronous vibrator, a sieve plate with dense openings, and the cyclone overflows the fine-grained tailing mortar with a concentration of 3%. To the thickener; the vibrating screen vibrates and dehydrates, and the water and a small amount of fine particles in the coarse-grained tailings mortar fall un...

Embodiment 2

[0030] Example 2 The tailings-200 mesh content of a mine is 61%, and the tailings slurry with a concentration of 18% is transported to the cyclone, and the cyclone generally uses a cyclone with a small-angle cone or a multi-cone structure , the classification limit of the cyclone is -10 μm, and the whole tailings slurry is divided into fine-grained tailings mortar and coarse-grained tailings mortar, and the underflow of the cyclone is dense coarse-grained tailings mortar with a concentration of 60%. For the first thickening, it is discharged to the vibrating screen, the cyclone overflows the fine-grained tailings mortar, and is transported to the thickener; the vibrating screen vibrates and dehydrates, and the water and a small amount of fine particles in the coarse-grained tailings mortar fall to the bottom of the sieve, and the sieve The above is the further dehydrated coarse-grained tailings mortar. At this time, the concentration of the coarse-grained tailings mortar reache...

Embodiment 3

[0031] Example 3 This system is applied to an iron mine in Anhui. The tailings of this mine have a -200 mesh content of 70%, which belongs to fine particle size tailings. The concentration of tailings discharged from the dressing plant is 18%, and the slurry is pumped to the cyclone. The cyclone generally uses a small-angle cone or multi-cone structure cyclone. The classification limit of the cyclone is -19μm. The whole tailings slurry is divided into fine-grained tailings mortar and coarse-grained tailings mortar. The underflow is thickened coarse-grained tailings mortar with a concentration of 65%. After the first thickening is completed, it is discharged to the vibrating screen. The vibrating screen adopts a dual-motor self-synchronous vibrator, a sieve plate with dense openings, and the cyclone overflows fine particles. The grade tailings mortar is transported to the thickener; the vibrating screen vibrates and dehydrates, and the water and a small amount of fine particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com