Nanometer spherical porous weak light photocatalyst for degrading nitrogen oxide, and preparation method and application thereof

A technology of nitrogen oxide and weak light, which is applied in the field of photocatalyst to achieve the effects of high film forming hardness, improved efficiency, and accelerated contact frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

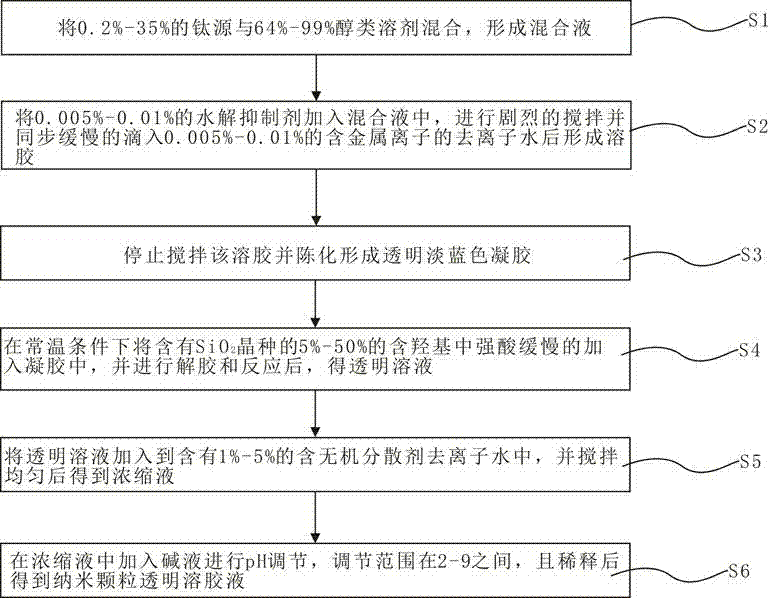

[0061] see figure 1 A method for preparing a nano-spherical porous weak-light photocatalyst for degrading nitrogen oxides provided by the invention comprises the following steps:

[0062] Step S1, mixing 0.2%-35% titanium source with 64%-99% alcohol solvent to form a mixed solution; in this step, the titanium source is n-butyl titanate, titanium tetrachloride, titanium trichloride, Any one of titanyl sulfate or ethyl titanate, the number of carbons in the alcohol solvent is 1-4, and it is absolute ethanol, n-propanol, isopropanol, n-butanol, sec-butanol or isobutanol any of the alcohols.

[0063] Step S2, adding 0.005%-0.01% hydrolysis inhibitor into the mixed solution, stirring vigorously and synchronously slowly dropping 0.005%-0.01% deionized water containing metal ions to form a sol; in this step, the hydrolysis inhibitor The agent is any one of glacial ester, acetylacetone, and concentrated hydrochloric acid, and the metal ion in deionized water containing metal ions i...

experiment example 1

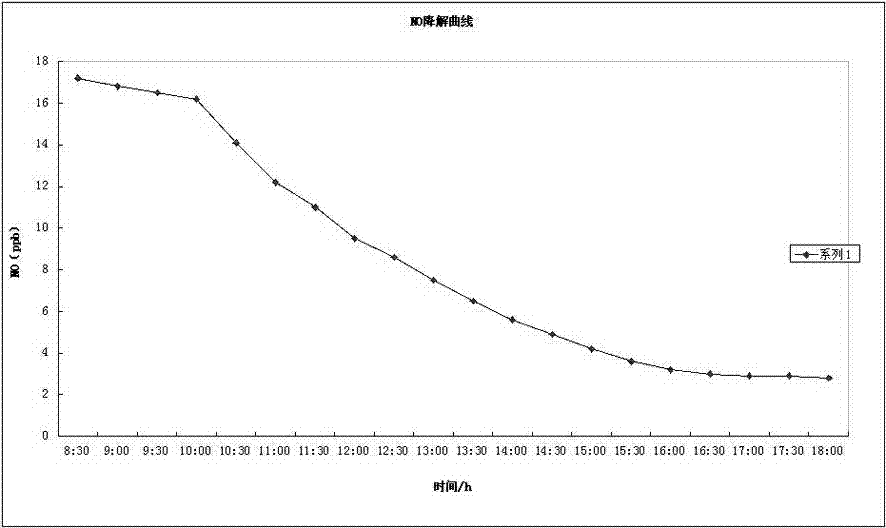

[0078] 1. Experimental method:

[0079] 1. Spray a certain amount of 0.5% nanoparticle transparent sol solution on a glass plate of 1 square meter, place it in a glass experimental chamber of 1.5 cubic meters, and fill it with a certain amount of standard concentration of nitrogen oxides under darkroom conditions Gas, and start the air circulation pump in the chamber, stop filling the nitrogen oxide standard gas when the concentration of nitrogen oxides in the chamber is stable at 160ppb. After the dark adsorption equilibrium (the process time is generally 0.5-1h, when the gas concentration change in the chamber is less than 4ppb / h, it is regarded as the dark adsorption equilibrium), and then test the NO and NO in three times within the next 1.5h. 2 concentration and record it. After the test, turn on the fluorescent lamp (wavelength range 400-800nm) in the warehouse for irradiation. Record NO and NO in the box every half hour 2 concentration.

[0080] 2. Experimental env...

experiment example 2

[0087] 1. Experimental method:

[0088] 1. Spray a certain amount of transparent sol solution with a concentration of 0.2% nanoparticles on a glass plate of 1 square meter, place it in a glass experimental chamber of 1.5 cubic meters, and fill it with a certain amount of standard concentration of nitrogen oxides under darkroom conditions Gas, and start the air circulation pump in the chamber, stop filling the nitrogen oxide standard gas when the concentration of nitrogen oxides in the chamber is stable at 160ppb. After the dark adsorption equilibrium (the process time is generally 0.5-1h, when the gas concentration change in the chamber is less than 4ppb / h, it is regarded as the dark adsorption equilibrium), and then test the NO and NO in three times within the next 1.5h. 2 concentration and record it. After the test, turn on the fluorescent lamp (wavelength range 400-800nm) in the warehouse for irradiation. Record NO and NO in the box every half hour 2 concentration.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com