Puffed hizikia fusiforme processing device

A processing equipment and hijiki technology, which is applied in the field of hijiki (expanded hijiki) processing equipment, can solve the problems of unsuitability for high-quality hijiki processing, time-consuming and labor-intensive quality, and unsatisfactory processing temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

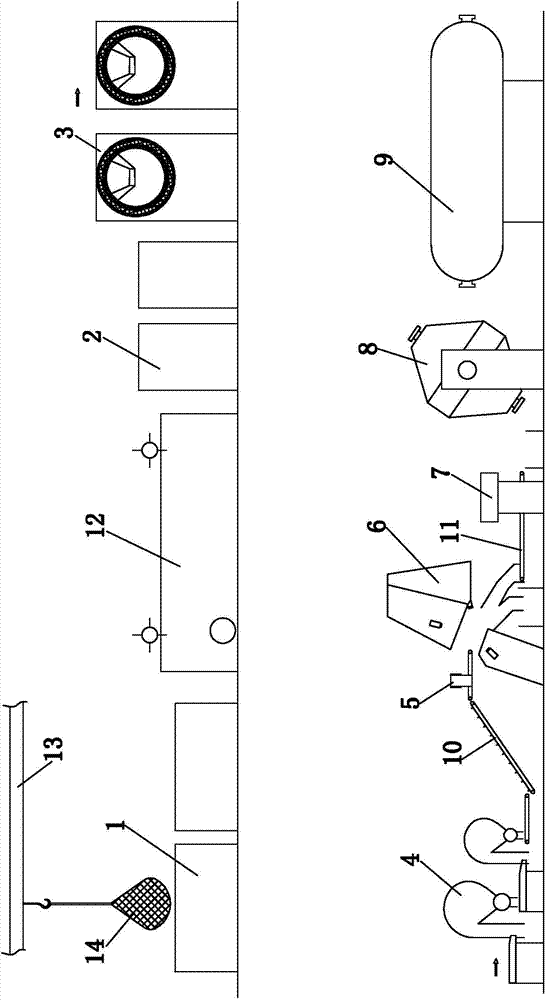

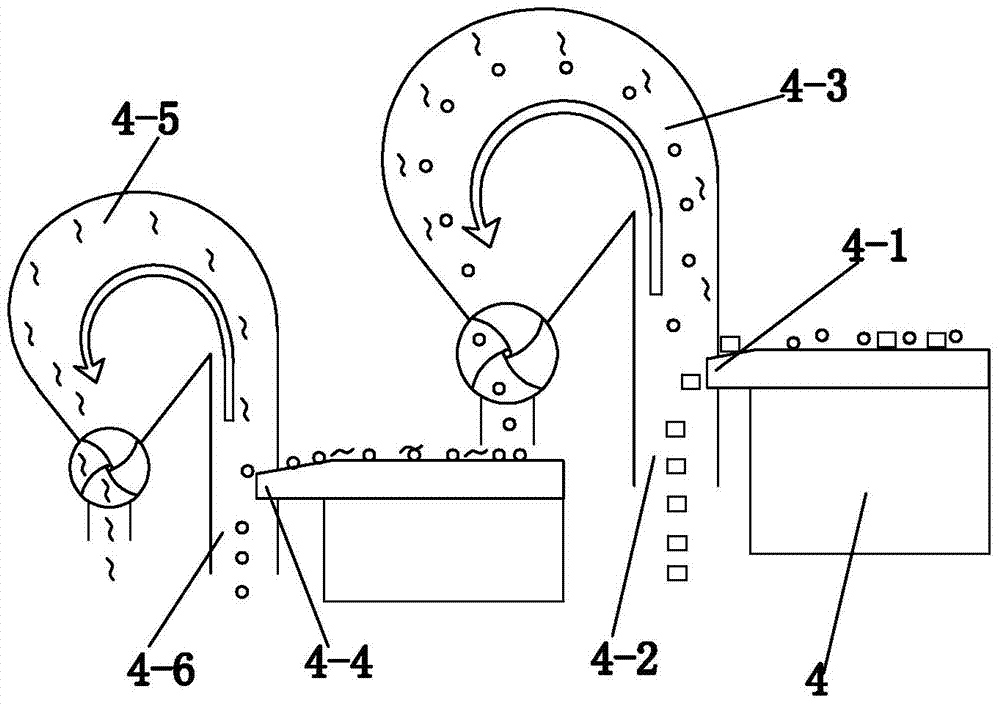

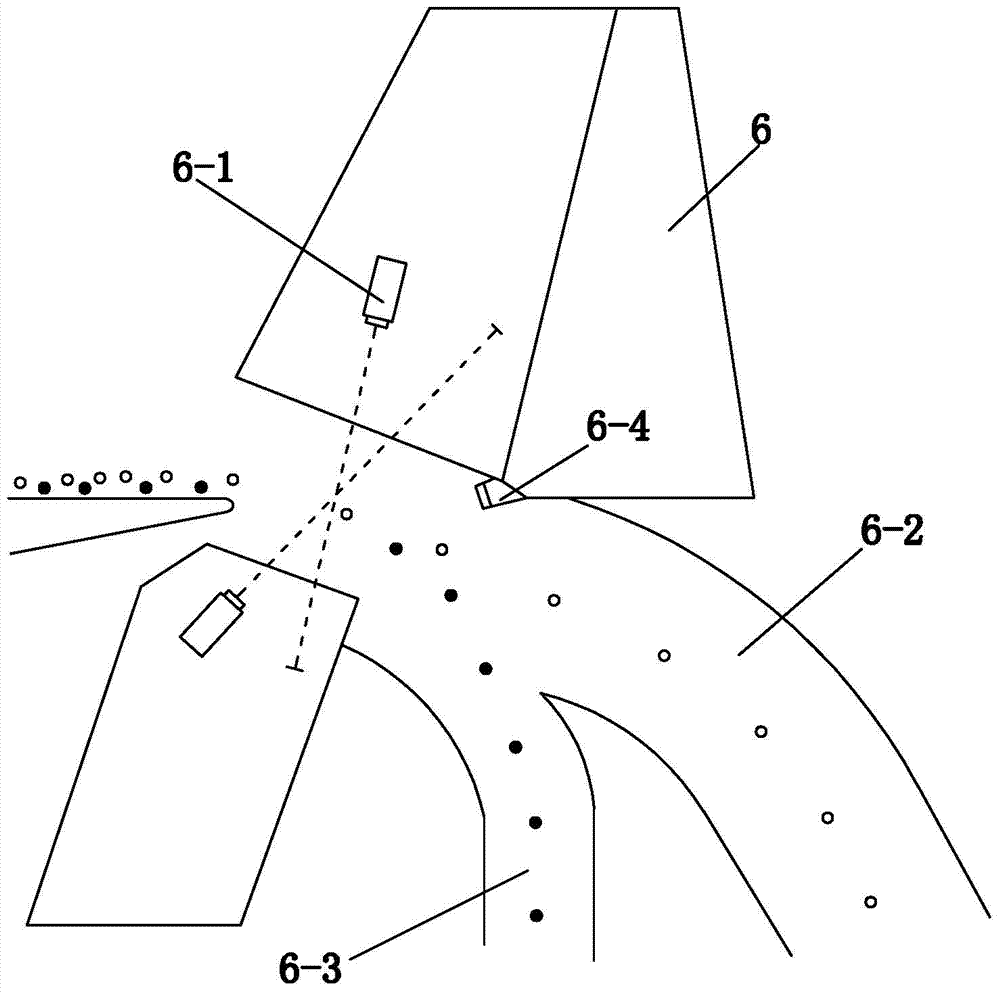

[0019] The present invention will be further described below in conjunction with specific embodiment: rice hijiki processing equipment of the present invention comprises soaking device 1, cooking device 2, automatic sorting device, drying device 8 and sterilizing puffing device 9 successively, arranges between each device The material conveying mechanism 10; the automatic sorting device includes a wind separator 4 that separates the material from impurities according to the weight difference through a blower mechanism, a magnetic separator 5 that absorbs and separates magnetic metals in the material through a magnet, and captures real-time images and presets Image comparison The color sorter 6 that separates the material from the impurities according to the color difference; the sterilization and puffing device 9 includes a silo, a steam conveying mechanism, a vacuuming mechanism, a pressure detection mechanism, a temperature detection mechanism, and detection parameters accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com