Method and device for electrodynamically braking a universal motor

A technology of electrodynamics and braking devices, applied in the direction of motor generator control, AC motor control, electrical components, etc., can solve the problems of armature wear, failure, unsuitable speed change, etc., and achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

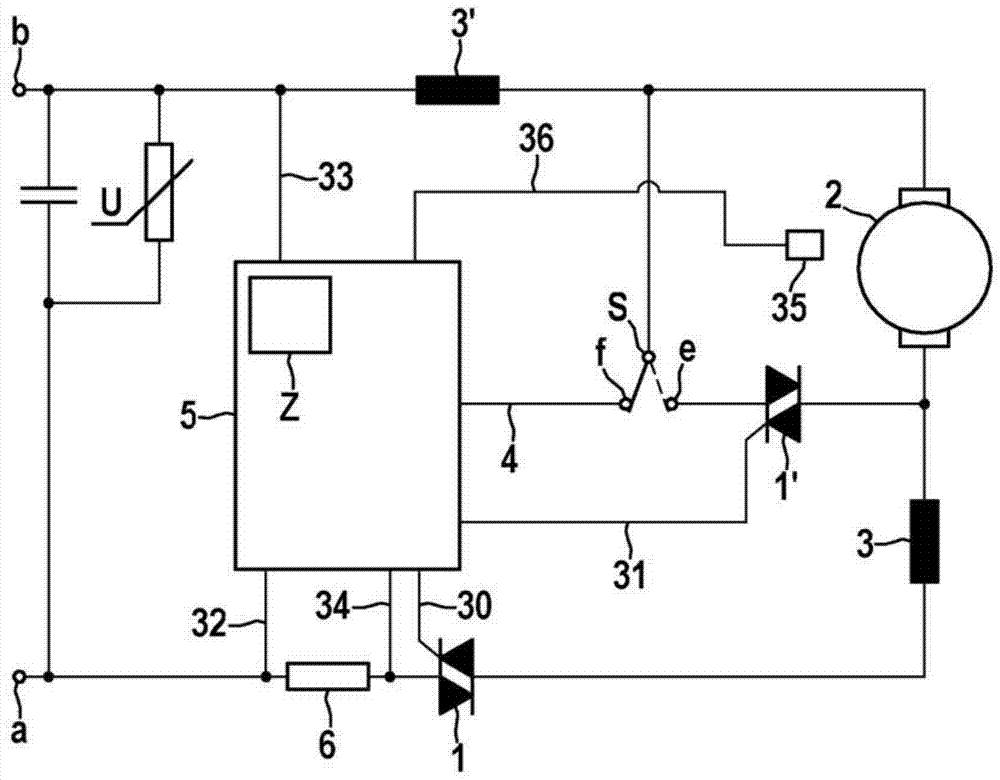

[0022] figure 1 A schematic circuit diagram of an electrodynamic braking device for an electric universal motor is shown. The device corresponds substantially to the assembly disclosed in WO2011 / 076827. The electrodynamic braking device has a command assignment Z within the electronic control unit 5 (which can be designed, for example, as a microcontroller circuit). Here, the assignment Z includes the firing angle of the second electronic semiconductor switch 1' A plurality of combinations of respective rotational speeds of the universal motor which result from the previously ascertained ideal braking operation of the universal motor. The rotational speed sensor 35 is provided for continuously ascertaining the rotational speed of the universal motor during braking operation. about figure 1 Further circuit and functional details of the components shown in are not described in depth as they are already known from WO 2011 / 076827.

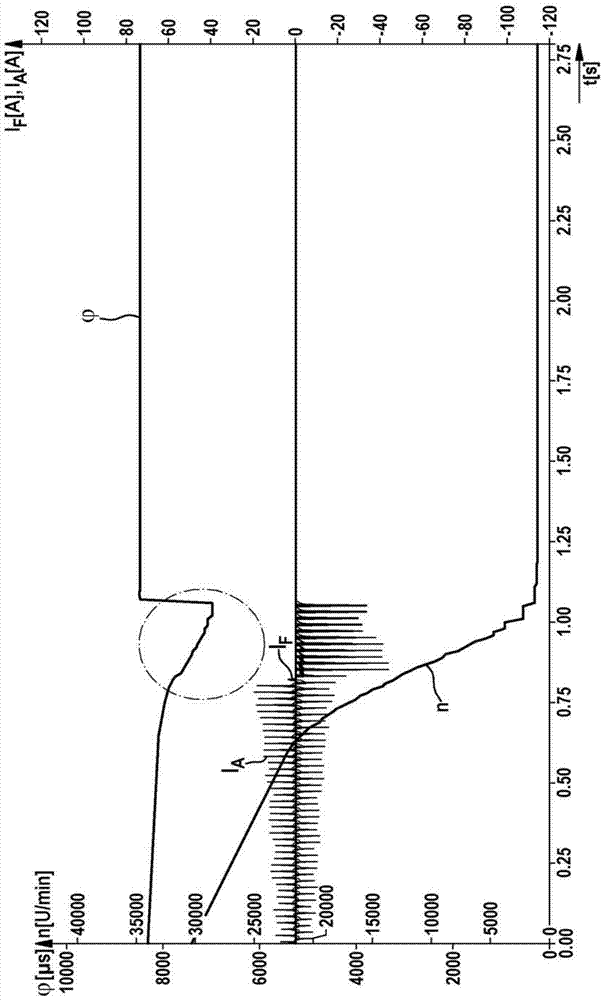

[0023] figure 2 shows a schematic time p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com