Preparation method for low-resistivity low-temperature P type aluminum gallium nitride materials

A low-resistivity, aluminum-gallium-nitride technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as severe acceptor compensation, achieve the effects of improving luminous intensity, low resistivity, and reducing series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

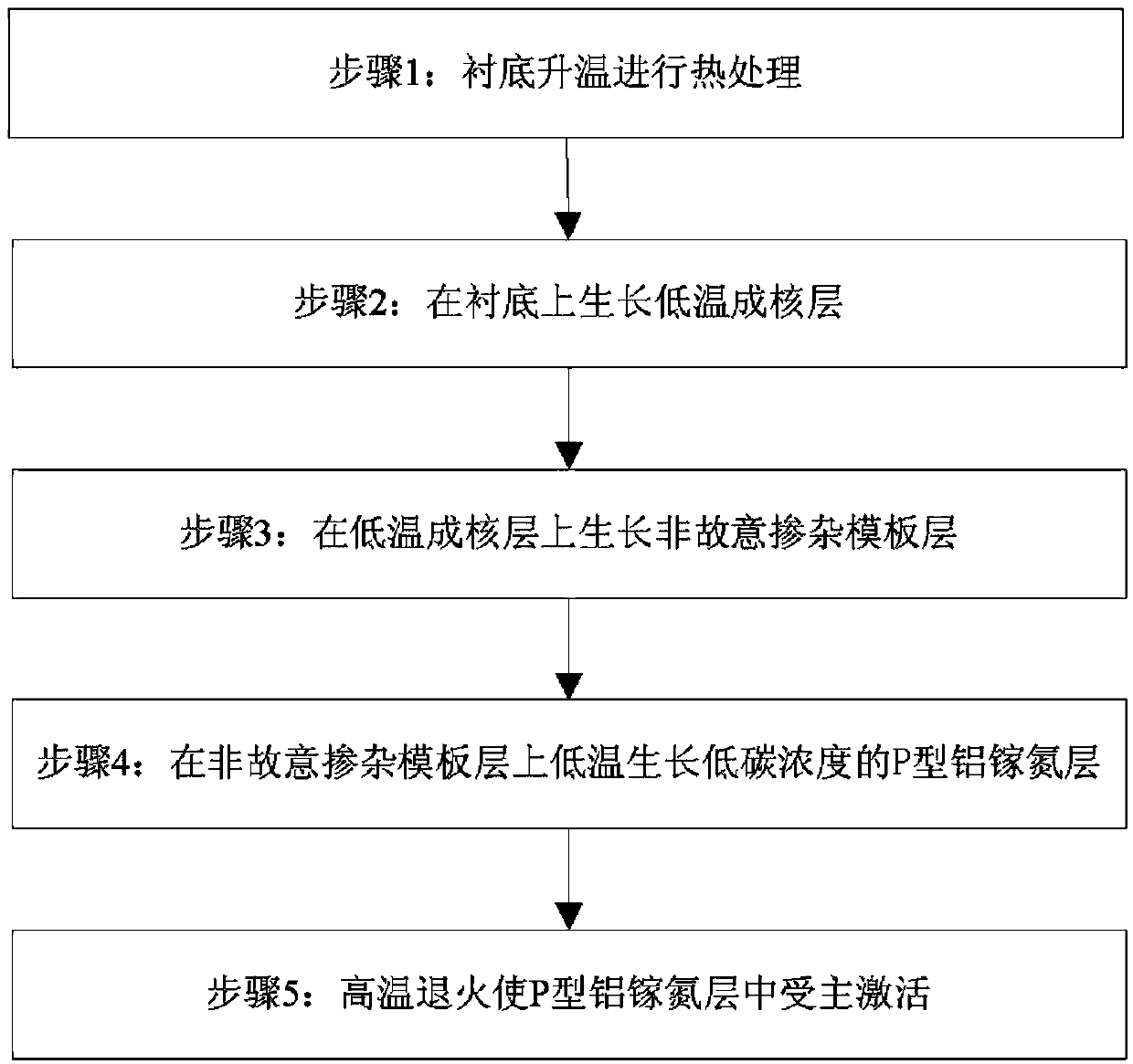

[0016] see figure 1 As shown, the present invention provides a method for preparing a low-resistivity low-temperature P-type aluminum gallium nitride material, comprising the following steps:

[0017] Step 1: heating up a substrate, heat treatment in a hydrogen environment, and removing impurities on the surface of the substrate. The material of the substrate is sapphire, silicon carbide or gallium nitride, and the heating temperature of the substrate is 1050-1080°C:

[0018] Step 2: grow a low-temperature nucleation layer on the substrate, the growth temperature of the low-temperature nucleation layer is 500-600°C, and the thickness is 20-30nm, and the material of the low-temperature nucleation layer is gallium nitride or aluminum nitride , the low-temperature nucleation layer provides nucleation centers for subsequent growth materials;

[0019] Step 3: grow an unintentionally doped template layer on the low-temperature nucleation layer, the material of the unintentionally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com