System and method for measuring equivalent heat conductivity coefficient

A technology of equivalent thermal conductivity and measurement system, which is applied in the direction of material thermal development, can solve the problems of not being able to obtain the relationship between the thermal physical properties of loose coal with temperature and the inability to obtain the thermal physical properties of loose coal at high temperatures, and achieve infinite The effect of gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

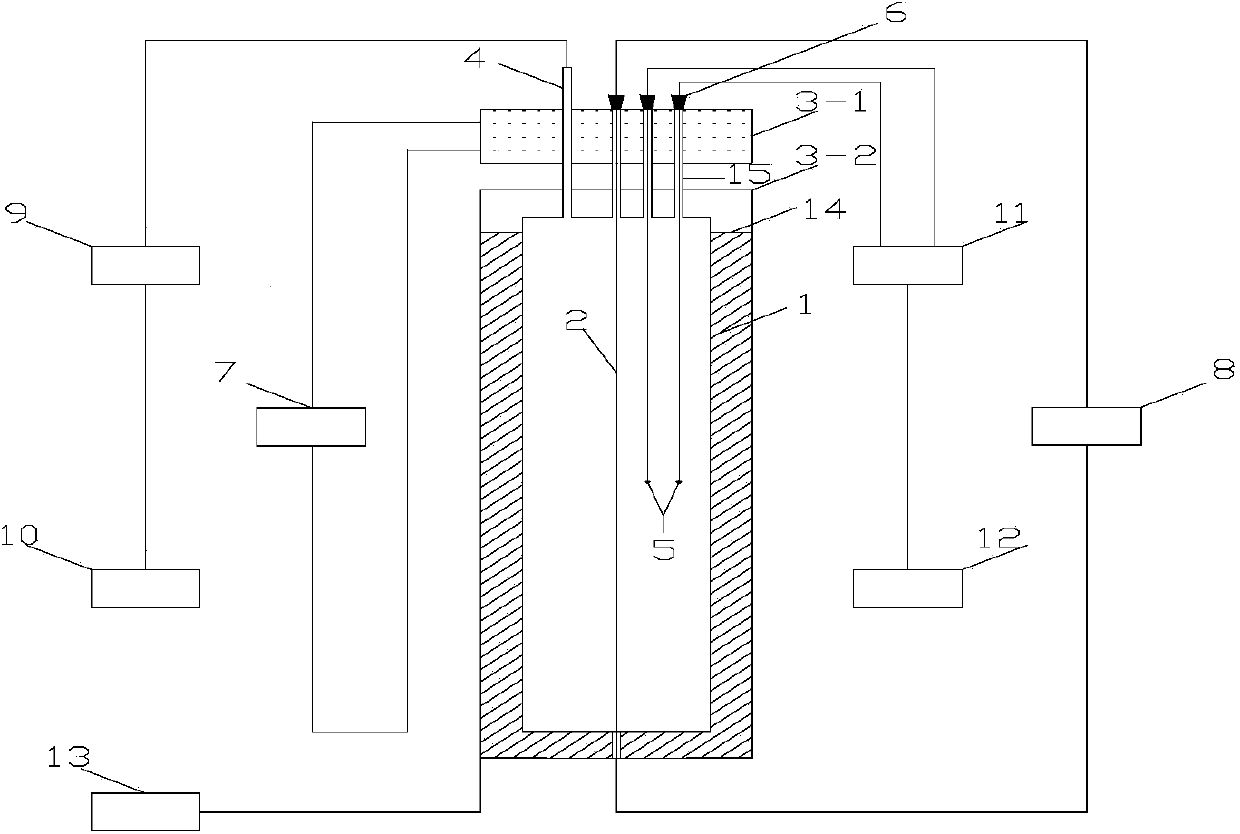

[0075] The best embodiment one: particle diameter is the mensuration of 30mm coal block equivalent thermal conductivity

[0076] 1. Insert a nickel-chromium heating wire with a diameter of 0.5mm on the axis of the sample cylinder, and set two thermocouple measuring points at 3mm and 5mm from the center of the hot wire, and ensure that the two thermocouple measuring points are in the same radial direction. on flat surface.

[0077] 2. Weigh 3.01kg of lump coal and randomly pile them in the sample cylinder, install a graphite gasket on the top of the sample cylinder, cover the cylinder cover, and pass the hot wire and thermocouple through the sealing tube on the cylinder cover, and use rubber The cap seals the sealing tube.

[0078] 3. Connect the gas collection pipe with the gas collection system; the upper part of the cylinder cover is connected with the circulating water device, and the circulating cooling water is introduced; the hot line is connected with the DC power supp...

Embodiment 2

[0084] The best embodiment two: particle diameter is the mensuration of 5mm solid waste equivalent thermal conductivity

[0085] 1. Insert a nickel-chromium heating wire with a diameter of 0.5mm on the axis of the sample cylinder, and set two thermocouple measuring points at 3mm and 5mm from the center of the hot wire, and ensure that the two thermocouple measuring points are in the same radial direction. on flat surface.

[0086] 2. Weigh 2.65kg of solid waste and randomly pile them in the sample cylinder, install a graphite gasket on the top of the sample cylinder, cover the cylinder cover, and pass the hot wire and thermocouple through the sealing tube on the cylinder cover, and use rubber The cap seals the sealing tube.

[0087] 3. Connect the gas collection pipe with the gas collection system; the upper part of the cylinder cover is connected with the circulating water device, and the circulating cooling water is introduced; the hot line is connected with the DC power su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com