Method for improving luminous intensity of (Y,Gd)AG:Ce fluorescent powder through modification of bismuth nitrate pentahydrate

A technology of bismuth nitrate pentahydrate and luminous intensity, which is applied in the direction of luminescent materials, chemical instruments and methods, can solve the problems of low color rendering index, low luminous efficiency, and reduced luminous intensity of white light LEDs, and achieve simple and high process requirements. The effect of low emission intensity and synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

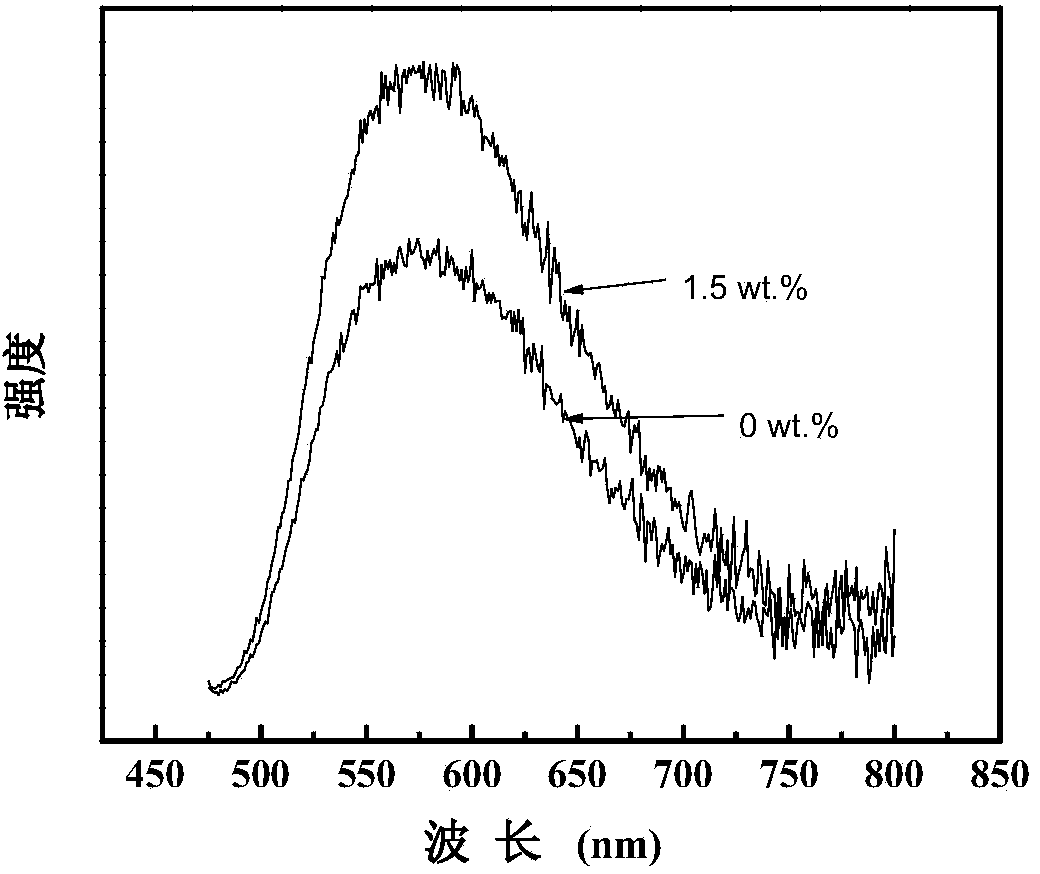

Image

Examples

Embodiment 1

[0029] Step 1. According to (Y 1.94 Gd 1 Ce 0.06 )Al 5 o 12 Chemical formula weighing 0.986g Y 2 o 3 , 0.816g Gd 2 o 3 , 0.117g Ce(NO 3 ) 3 ·6H 2 O and 8.438g Al(NO 3 ) 3 9H 2 O, then put the weighed Y 2 o 3 and Gd 2 o 3 Dissolve in nitric acid solution and stir well to produce yttrium nitrate and gadolinium nitrate, then dissolve yttrium nitrate, gadolinium nitrate, aluminum nitrate and cerium nitrate in 130mL deionized water to prepare 0.067mol / L yttrium nitrate, 0.035mol The mixed nitrate solution of / L gadolinium nitrate, 0.002mol / L cerium nitrate and 0.173mol / L aluminum nitrate;

[0030] Step 2, drop the prepared mixed nitrate solution into the ammonium bicarbonate solution using the back-drop coprecipitation method, wherein the 0.728mol / L ammonium bicarbonate solution includes a mass fraction of 3.5% of the nitrate in the mixed nitrate solution Sodium lauryl sulfate, ensure that the pH value is 7.2 during the titration process, and leave it to age at ro...

Embodiment 2

[0036] Step 1. According to (Y 1.94 Gd 1 Ce 0.06 )Al 5 o 12 Chemical formula weighing 0.986g Y 2 o 3 , 0.816g Gd 2 o 3 , 0.117g Ce(NO 3 ) 3 ·6H 2 O and 8.438g Al(NO 3 ) 3 9H 2 O, then put the weighed Y 2 o 3 and Gd 2 o 3 Dissolve in nitric acid solution and stir well to produce yttrium nitrate and gadolinium nitrate, then dissolve yttrium nitrate, gadolinium nitrate, aluminum nitrate and cerium nitrate in 130mL deionized water to prepare 0.067mol / L yttrium nitrate, 0.035mol The mixed nitrate solution of / L gadolinium nitrate, 0.002mol / L cerium nitrate and 0.173mol / L aluminum nitrate;

[0037] Step 2, drop the prepared mixed nitrate solution into the ammonium bicarbonate solution using the back-drop coprecipitation method, wherein the 0.728mol / L ammonium bicarbonate solution includes a mass fraction of 3.5% of the nitrate in the mixed nitrate solution Sodium lauryl sulfate, ensure that the pH value is 7.4 during the titration process, and leave it to age at ro...

Embodiment 3

[0043] Step 1. According to (Y 1.94 Gd 1 Ce 0.06 )Al 5 o 12 Chemical formula weighing 0.986g Y 2 o 3 , 0.816g Gd 2 o 3 , 0.117g Ce(NO 3 ) 3 ·6H 2 O and 8.438g Al(NO 3 ) 3 9H 2 O, then put the weighed Y 2 o 3 and Gd 2 o 3 Dissolve in nitric acid solution and stir well to produce yttrium nitrate and gadolinium nitrate, then dissolve yttrium nitrate, gadolinium nitrate, aluminum nitrate and cerium nitrate in 130mL deionized water to prepare 0.067mol / L yttrium nitrate, 0.035mol The mixed nitrate solution of / L gadolinium nitrate, 0.002mol / L cerium nitrate and 0.173mol / L aluminum nitrate;

[0044] Step 2, drop the prepared mixed nitrate solution into the ammonium bicarbonate solution using the back-drop coprecipitation method, wherein the 0.728mol / L ammonium bicarbonate solution includes a mass fraction of 3.5% of the nitrate in the mixed nitrate solution Sodium lauryl sulfate, ensure that the pH value is 7.6 during the titration process, and leave it to age at ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com